By Matt Swartz and Scott Brady

Editor’s Note: This article was originally published in Overland Journal’s Winter 2022 Issue.

Few vehicles offer the overland traveler versatility, utility, and flexibility like a pickup truck. But that doesn’t mean it’s the perfect platform. Pickup trucks are kind of like a blank canvas, offering loads of potential in the way of payload, hauling capability, and cargo space in the bed. Until they’ve been properly accessorized, though (not to be confused with excessively), they can leave a lot to be desired. With so many truck accessories available from the leading manufacturers promising to catapult the customer to overland glory, where does one even begin?

For this test, we’ve elected to start where we think you can gain a large amount of utility: with a truck bed rack system. Think of this addition as a foundation, the framing of your overland travel system. A bed rack creates the structure needed to securely mount rooftop tents (RTTs), cargo boxes, recovery boards, or hand tools. It establishes solid lashing points to secure coolers, spare tires, and some even allow you to move your gear onto a tray system, opening up the bed of your truck for a minimalist sleeping platform or even more equipment.

As you might have guessed, not all bed racks are created equal. They come in a variety of configurations, from svelte to supreme. Some feature simple crossbars, like a traditional roof rack, while others have rectangular trays with T-slotted slats that let you bolt on all of the accessories. To give you a good profile of the market, knowing that travelers often have differing needs, we’ve sourced six of the leading pickup truck bed racks and pitted them against each other—building, installing, and taking them into the field. This is by no means a comprehensive list; nonetheless, the following article provides a starting point if you are looking to outfit your truck to venture farther down the trail. (MS)

Testing Considerations

When considering a rack for your truck, there are three primary attributes: convenience, capacity, and configurability. Understandably, there are no racks in this test that completely deliver on all three, and some get closer than others. It is important to note that having all of these attributes would not even be optimal in many cases.

Some users rely on convenience when purchasing a rack and want a model that can be installed and removed quickly and is light enough or easy enough to disassemble by a single person. These racks are intentionally minimalist, serving the primary function of supporting a platform, rooftop tent, or a few accessories. These are also ideal for mounting a stand-up paddle board or a few mountain bikes. These racks tend to be less expensive, offer fewer accessories, and sit lower to the bed height (although some are adjustable).

For other travelers, they are focused on capacity, with the intention to mount a heavy rooftop tent or a large platform with a tent, boxes, and tools. The rack mounting is more complex, with additional supports, robust uprights, and limited (or no) adjustment to height and crossbar position. These are semi-permanent installations designed to be left on the vehicle, have wiring integrated, and even include storage lockers or side panels. They are often rated for high static loads to support multiple occupants of a rooftop tent.

The last attribute is configurability (utility), which becomes the Lego or erector set of the rack world. These models often include a large suite of accessories, adapters, and support components. Configurability is important in many applications, as the pickup’s utility can be retained or even used for commercial purposes during the work week. Increasingly, racks of this type will have MOLLE panels and other plates that limit access from sticky fingers and allow you to mount traction boards, etc.

While there are racks that may emphasize one of these categories, they often overlap, and several in this review satisfy more than one feature set. But a primary use case should first be identified, which can save money and reduce frustration.

For objective testing, we focused on the material quality of the components, the mounting durability, and the deflection of the structure. We used a dial indicator to determine deflection, measuring fore/aft and side/side flex. We tested both a steady deflection load and a dynamic one. The dynamic load was insightful, as it revealed weaknesses in the mounting system, uprights, and connection joints. The dial indicator results were plotted on a bell curve, with the most structurally sound unit achieving excellent, followed by good, average, and poor. It is important to note that we were not looking for the most rigid structure but the most robust. Some deflection is part of good engineering and allows for bed flex.

Subjective testing included installation time and difficulty, rack usability, accessory availability, and overall suitability for overland travel. We used the racks in the field for many nights of camping and utility duties. The Yakima, for example, has lived on both a Chevrolet Bison and a Toyota Tacoma. These prolonged uses on numerous test platforms provided insights into day-to-day functionality and durability and informed how the product best serves the overlander. (SB)

Putco Venture Tec

Putco is a 50-year-old US company specializing in manufacturing premium automotive components, including their new line of overland components. They produce most of the parts in their 140,000-square-foot Iowa facility, servicing the aftermarket and OEM customers like Ford, GM, Mopar, and more.

The Venture Tec is an all 6061 T6 aluminum modular rack that combines a one-piece front and rear structural hoops with full-length extruded lower support tubes. The top tube provides additional support and becomes the load surface for the crossbars. Further support is gained by installing the MOLLE panels. The front and rear hoops make for an exceptionally rigid structure, especially off-road, as side-to-side loads are best managed by the one-piece units. This does come with a compromise, as motorcycles or taller items cannot be loaded into the bed.

One of the more notable advantages of this system is the full range of accessories, which include MOLLE panels for both sides (in two sizes), a full-length-closed mounting plate, rooftop tent brackets, handles, tables, lighting, and even a license plate bracket. The panels are particularly useful since they help to enclose the rack, limiting theft. It would be interesting to see a rear panel for the system, too, making for a full cage.

Installation was straightforward and did not require any drilling, but it does take several hours due to the volume of small Allen head bolts that need to be used. Most interface joints on the rack require four bolts each, with the captive nuts slid down or along an extrusion channel. While not difficult, it does require patience and benefits from a cordless screw gun with a clutch to prevent stripping. Along the same vein, some of the accessories use a thinner gauge sheet aluminum, which results in the bolts bottoming on the rails and not being flush at the bolt head. This did not affect function or testing performance, and I suspect future versions will address this.

In use, the Venture Tec was one of the best racks for utilizing a rooftop tent, being at the perfect level to the GMC cab. The iKamper Skycamp that we installed fit without the rooftop tent brackets and sat at just the right height to optimize trail clearance and aerodynamics. The table is also a practical accessory with a metal surface for camp and repair work duties. The bare rack weighs just over 50 pounds, one of the lighter systems in the test.

Performance and rigidity were good, with the rack deflecting .015 of an inch from side to side, then .022. This is primarily due to the size of the extrusions and the number of supporting rails. The only limitation is at the bed attachment point, which only uses four 7/16-inch bolts that attach to brackets to secure to the bed’s sides via the stake holes. We did note that regular inspection was necessary, and the structure did move around on the bed rails slightly, leaving witness marks on the rail caps. (SB)

$1,865 | putco.com

Load ratings are as follows: 600 pounds on-road, 300 pounds off-road, 1,000 pounds static

Deflection Scoring:

- Rack = Good

- Mounting = Poor

Pros

- Lightweight

- Extremely rigid structure

- Numerous accessories

- Appropriate rack height for fitting an RTT

Cons

- Assembly requires dozens of small screws that need to be checked regularly

- Does not allow for loading a motorcycle

- Attachment to the bed is easy but less robust

EDITOR’S CHOICE: Leitner Design Forged Active Cargo System

Leitner Design began in 2007 as an engineering and R&D company, assisting organizations with developing manufactured products for the motorcycle, automotive, and action sports markets (among others). These learnings resulted in Founder Bernard Leitner shifting the company’s focus to creating their own line of truck accessories, including the Active Cargo System (ACS) tested here. Their products are designed and made in the USA.

The Forged Active Cargo System is an evolution of their classic tubular model, which was proven for nearly a decade in multiple applications. In 2019, Leitner launched the new version, which combined their learnings from the still-sold tubular model to incorporate all aluminum forged uprights and support braces. The rail, top bar, and load bar are all extruded aluminum, installed with fasteners and support brackets. Upon initial inspection, the most notable feature of the Forged ACS is the robust and attractive uprights, showcasing its reinforcing ribs and a premium appearance.

The Leitner was installed on a 2021 Ram 1500 TRX owned by Adventure Imports, who also performed the installation and was interviewed regarding the process for this article. The undertaking was described as intermediate in time and difficulty, with numerous brackets and fasteners. It is necessary to drill into the interior sides of the truck bed and install several rivet nuts. This all takes a few hours and a measure thrice philosophy. The rack’s installation is well-documented with a comprehensive PDF instruction manual and accompanying YouTube video.

Once installed, the merits of the Leitner ACS are immediately apparent, with an 85-pound superstructure of forged and extruded aluminum. It is not only rigid but can be adjusted and configured to the needs of the traveler. The load bars can be quickly removed to allow loading of a motorcycle, and other accessories can be installed to support the fitment of MaxTrax, awnings, a Hi-Lift jack, and even their 2nd-generation rotomolded GearPod storage lockers.

Testing conditions showed limited deflection from side to side, never exceeding .044 of an inch even under dynamic inputs. There was more fore and aft deflection, approaching .052 of an inch with dynamic loading. We did not experience rattling or failures of the rack structure, but we did note cracking from metal fatigue on the MaxTrax mounting bracket; however, the truck was used for a rally competition, which would exceed the vibration and impact conditions of most persons.

The Leitner ACS forged rack has several key attributes, including the overall rigidity and durability of the structure and the ability to easily reconfigure it for multiple uses. When the test-exclusive GearPod storage units and their new HydroPod shower system are also considered, this rack is one of the test’s most comprehensive solutions. (SB)

$1,950 | leitnerdesigns.com

Load ratings are as follows: 800 pounds on-road, 400 pounds off-road, 1,400 pounds static

Deflection Scoring:

- Rack = Excellent

- Mounting = Excellent

Pros

- Premium design and materials

- Rigid and durable structure

- Wide range of accessories, including the GearPod

Cons

- Requires drilling the truck bed

- T-slots can be challenging to move

- Requires regular fastener inspection and torquing

BajaRack

BajaRack manufactures gear to take adventurers beyond the trail that can survive the rigors of the Baja Peninsula and, ultimately, the infamous Baja 1000.

They are headquartered in San Diego, California, and manufacture their racks in, Ensenada, Mexico, using US-sourced cold-rolled steel (although the model we reviewed is made from aluminum). Baja’s affordable yet rugged racks are designed with the latest CAD technology and always take into account customer feedback in an effort to provide the best possible end product.

For our bed rack test, we sourced and installed Baja’s 3rd-Gen Toyota Tacoma bed rack on a short bed 2020 TRD Off-road model. Prospective buyers should note that bed track hardware is specific to the vehicle, so be sure to procure the correct hardware when ordering.

Upon initial unboxing and inspection, the powder-coated BajaRack components appeared very robust. I especially liked that the rear cross member of the rack had an integrated brake light.

Installation was accomplished using a wrench and socket and didn’t require any drilling or vehicle modification. When installing, I initially made the mistake of using the wrong hardware, resulting in the rack sitting about a half-inch above the Tacoma’s bed rails. This mistake was quickly remedied by using the correct hardware.

The C-shaped structural components of the BajaRack inspired confidence in their structure, especially once all bolts were fully tightened. Their open nature lends to easy wire routing for auxiliary components requiring power. However, there is limited flexibility regarding the placement of the upper crossbars, which only come in one width. Only the middle of the three can be strategically placed in multiple places along the upper portion of the rack. Most users will want to locate it in the center of the rack to evenly distribute the load of a rooftop tent or other cargo; putting it anywhere else may affect the rated cargo capacity of the rack. The crossbars are not easily removable, a quality that is important to know about for those who may need to haul a motorcycle in the bed of their trucks.

Thanks to the height of the upper crossbars, which sit just above the cab of the vehicle, the BajaRack can support cargo that extends forward above the truck’s cab, such as lumber and kayaks. For trucks that are utilized for work and play, this design element may be appealing. Given that the rack is designed with overland travel in mind, many bolt-on brackets are available, including mounts for traction boards, a Hi-lift jack, hand tools, awnings, and more. Thanks to many bolt holes distributed evenly throughout the structural members of this rack system, attaching additional hardware from other manufacturers seems like it would be relatively easy.

Taking the BajaRack through our test course, no rattling or notable driving noises were noted. (MS)

$1,490 | bajarack.com

Load ratings are as follows: 850 pounds static, 600 pounds dynamic

Deflection Scoring:

- Rack = Excellent

- Mounting = Average

Pros

- Easy to assemble

- No vehicle modification needed for install

- Integrated third brake light

Cons

- Crossbars are not easily removable

- Fixed height

VALUE AWARD: Front Runner Slimline II Load Bed Rack Kit

The genesis of Front Runner Outfitters is not dissimilar to other overland equipment companies. A group of traveling friends was sick and tired of their overland gear breaking. Given their backgrounds in engineering, design, manufacturing, and off-road racing, they knew that they could come up with better solutions. Their proving grounds would be the African bush, so their gear needed to be “stronger than the elephants at the watering hole 1 klick over.” Currently, Front Runner’s manufacturing facility is located just outside of Johannesburg, South Africa, and features laser cutting, bending, and powder-coating processes.

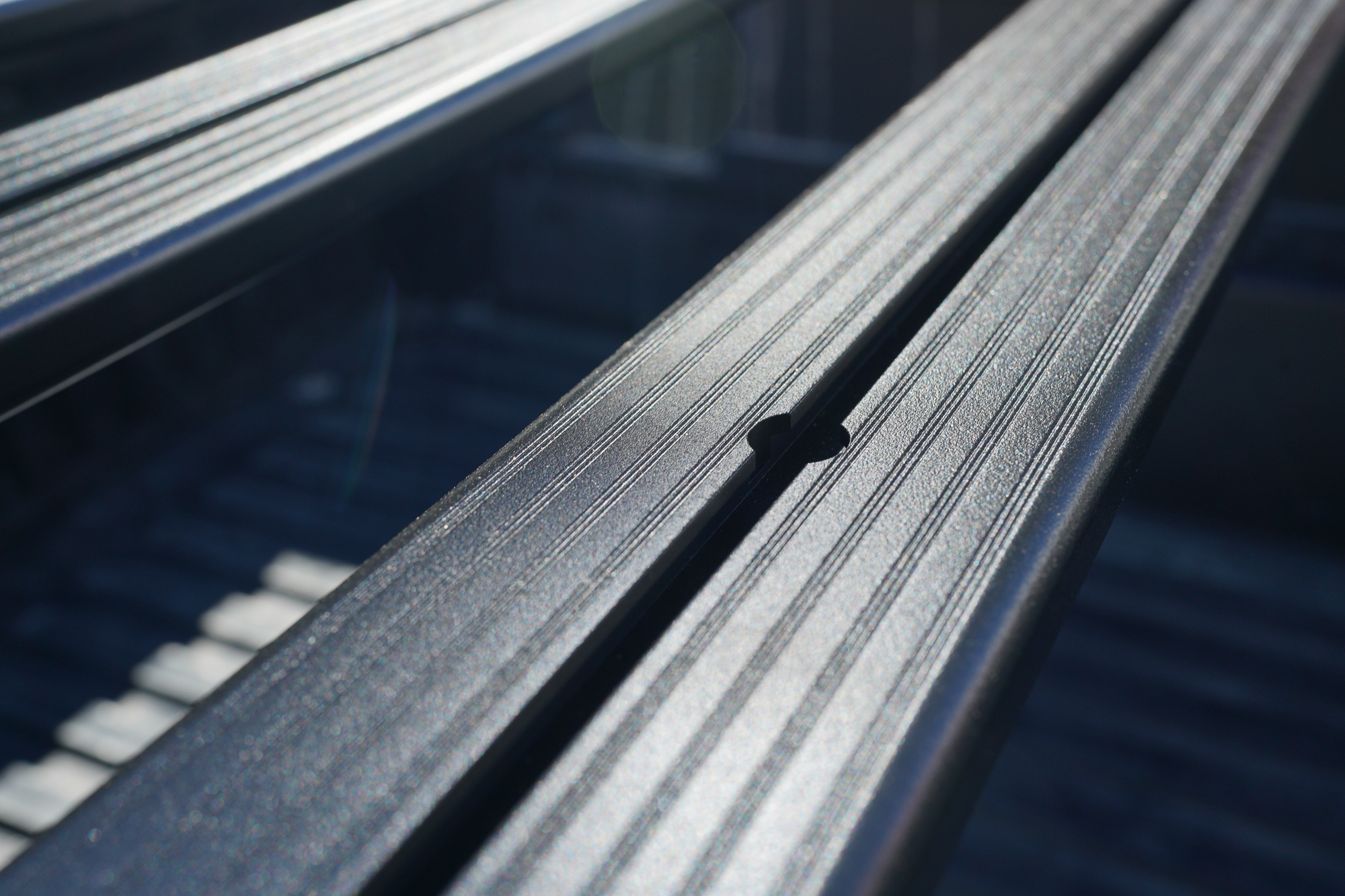

For our test, we sourced Front Runner’s flagship cargo tray system, the Slimline II Load Bed Rack kit, and installed it on a 2010 double-cab four-door Toyota Tacoma. The Slimline II tray is basically a rectangular platform constructed from extruded aluminum slats that feature T-slots for bolting all manner of accessories almost anywhere you could want.

Putting the tray together in the Overland International shop was relatively straightforward, but some steps of setup felt much easier with the help of a second person. Fitting the Slimline to the bed of the Tacoma with the included towers was a little bit challenging. Once everything came together and was tightened down, though, the entire system felt surprisingly rugged. Despite this apparent solid construction, I find myself wondering why Front Runner doesn’t utilize a third tower on each side to help distribute the load of the tray. It’s conceivable to think that this small addition might help augment the suggested 150-pound load rating of this product (more on this below).

The overall appearance of the Slimline II system is handsome yet minimal, and there are an incredible number of accessories and mounts available directly from Front Runner. One that we found especially appealing allowed us to integrate Front Runner’s stainless steel prep table underneath the tray. The execution of this table mount was nearly perfect, but the tolerances could be a little bit tighter to prevent vibration of the table in the mounts. We also tested Front Runner’s recovery device-side mounts with a set of MaxTrax, and it worked perfectly.

The only thing that had us scratching our heads in regard to the Slimline II system was that Front Runner doesn’t recommend exceeding 150 pounds of cargo on the tray. They provide the following explanation on their website:

“Due to load limitations of the factory bed tracks, we do NOT advise loading more than 150 pounds (68 kilograms). While Front Runner racks and mounting systems have been engineered and built to hold 660 pounds/299 kilograms, this may exceed your vehicle manufacturer’s recommendations. Until all vehicle components are made as off-road tough as Front Runner’s, we suggest contacting your vehicle maker to check load limits before aggressive loading of the rack.” (MS)

$1,195 | frontrunneroutfitters.com

Load ratings are as follows: Front Runner states that although this rack is engineered to support 660 pounds of cargo, it should not be loaded with more than 150 pounds if installed via the OEM bed track system.

Deflection Scoring:

- Rack = Average

- Mounting = Average

Pros

- Affordable (in our range of test products)

- Many accessories and mounts

Cons

- Ambiguity of load rating

- Fixed height

Rhino-Rack Reconn-Deck Pioneer Platform Truck Bed System

Rhino-Rack got its start back in 1992 when Founder Rich Cropley began selling his first products in Haberfield, New South Wales, Australia. Like many companies in the overland space, Rich was unimpressed with what the market had to offer and knew he could improve on it. To make a long story short, 30 years later, Rhino-Rack was purchased by Clarus Corporation for close to $200 million, a testament to the quality and popularity of the company’s offerings.

Regardless of the Rhino-Rack’s successes, conservation and giving back have always been a meaningful facet of their overall business model. They have been ongoing supporters of rhinoceros conservation in Africa and support cancer research and studies via a portion of their awning sales.

For our test, I had the pleasure of installing Rhino’s lightweight aluminum Reconn-Deck system on a 2019 Toyota Tacoma double-cab long-bed pickup. The installation process was fairly straightforward and didn’t require any vehicle modification. Having a second person to help was appreciated, especially when assembling the tray.

Of the three rack systems I installed for our review, the Pioneer had the most nuts and bolts to tighten down. Its tray had more structural members than similar products, a quality that I suspect was responsible for its above-average performance in our deflection testing. This may have also been partially due to its wider towers, each of which had three integrated clamps for a total of 12 clamp points along the Tacoma’s bed track.

When it comes to accessorizing the Pioneer, Rhino-Rack has designed the Pioneer with multiple T-slot tracks—on the towers, as well as on the top and bottom of the tray slats. This allows users to attach a wide selection of accessory brackets for mounting shovels, lighting, antennas, awnings, and more. Non-Rhino aftermarket accessories should easily integrate, thanks to this versatile design. Even without having Rhino’s recovery board mount on hand, we were still able to secure a pair of MaxTrax using bungee straps.

The fit and finish of the Pioneer tray system were excellent, although we thought that covers for the inside of the towers might improve the overall visual appeal and prevent anyone from tampering with the rack’s hardware. For those who plan to haul additional cargo in the bed of their trucks, be aware that the clearance to the bottom of the tray is sufficient for hard-sided containers but won’t allow for larger items like motorcycles.

$1,481 | rhinorack.com

Load ratings are as follows: 660 pounds static, 264 pounds dynamic

Deflection Scoring:

- Rack = Good

- Mounting = Good (quality of uprights is notable)

Pros

- Rigidity of load towers was excellent

- Versatile design compatible with non-Rhino accessories

Cons

- Lower dynamic load rating

- Limited bed clearance presents some cargo-hauling limitations

Yakima OutPost HD System

Yakima is one of the most widely recognized and well-established manufacturers of vehicle roof rack systems, which they’ve been offering for close to 40 years. And while they initially got their start as a machine shop, Yakima has expanded significantly, manufacturing everything from bike racks, cargo boxes, rooftop tents, and, you guessed it, truck bed racks.

When it came to testing a Yakima product for this article, we were fortunate that one of our team members, Lisa Williams, already owned the Outpost HD bed rack system and had it installed on her double-cab, long-bed 2019 Toyota Tacoma. However, this meant we didn’t have the opportunity to install the system ourselves. Lisa reported that the original product installation was straightforward and didn’t propose any significant challenges for her. The process did not require any vehicle modifications and utilized her truck’s OEM bed track system. Additionally, Lisa’s system incorporated Yakima’s OutPost HD crossbars, SideBars, recovery track mounts, and bed track kit (optional equipment).

While I can’t comment on the entirety of the OutPost build and installation, I did take it off to test another bed rack; the task required removing eight bolts. It’s worth mentioning that those bolts are theft-proof and require a Yakima-branded hex tool that is not readily available and may need to be special-ordered if lost.

Accessorization of the OutPost is unnecessary but will provide added structure and mounting points for gear like recovery boards, hand tools, and more. We tested this rack with a set of MaxTrax, an awning, and a rooftop tent mounted.

Although the overall build of the OutPost appeared to be robust, and there was a limited amount of movement/vibration on the trail, upon inspection, we noted several bolts which had vibrated out of various parts of the rack. This observation did not necessarily lead us to believe that there are any design issues with this product; instead, it reminded us that regular use of equipment in off-highway terrain might dictate frequent inspection of bolt torque values. It may justify the use of threadlock to prevent unwanted loosening of hardware unless it is expressly discouraged by the manufacturer.

The main limitation of the OutPost system is its fixed 13-inch heigh, which poses a problem if you want to haul tall items like a motorcycle. The crossbars could be removed from the towers to provide more vertical clearance, but it may be easier to simply remove the entire rack for these special situations. Despite this design, the rest of the rack had some thoughtful elements, like T-slot channels on the side bars, a quality powder-coated finish, rubber padding on the HD crossbars, and integrated locking mechanisms to deter theft of the various parts of the system.

$899+ ($1,397 as tested) | yakima.com

Load ratings are as follows: 500 pounds on-road, 300 pounds off-road

Deflection Scoring:

- Rack = Average

- Mounting = Good (quality of the uprights is notable)

Pros

- Well-established manufacturer

- Intelligent design and details

Cons

- Specialty installation tools can be difficult to replace if lost

- Fixed height

Conclusions

The popularity of mid-size and full-size trucks has redefined the overland market, and with it, we have a wide array of new products to modify these trucks to our needs. The truck bed changes everything, and these racks allow us to bring nearly everything. However, our testing did reveal significant characteristics and usability requirements that helped several models rise to the top.

Editor’s Choice Award

For the Editor’s Choice, Matt and I focused on the key overland attributes of durability, capacity, and supportive accessories, and it came down to the Front Runner, Leitner, and Putco. The Front Runner has the best platform in the test and one of the most comprehensive accessory offerings in the industry. It will be the best choice for overlanders looking to keep their weight down and their load low. With the supports being one of the lowest in the test, this subsequently restricts the type of tent (for example, a hard shell will not work) or adventure toys you can bring along. It would need to be removed to load a motorcycle, and the dynamic load ratings are some of the most conservative in the review. The Putco has a comprehensive accessory list, including several unique offerings like a table and MOLLE panels. The structure is impressively rigid once all of the support bars are installed, and it sits at the perfect height to install a full-size hard-shell rooftop tent, kayaks, or stand-up paddleboards. Our two concerns with the rack are the attachment points, which rely entirely on four modest bolts to keep the rack attached to the bed. The rack is bomber, but the attachment allows for movement. For me, the permanent rear crossbar of the Putco also restricts loading a motorcycle or other larger items in the bed. In this test, only the Leitner that rose to the top of every category, being light enough, robust enough, and configurable enough for nearly every overland scenario. The structure is impressively sturdy, including additional bed supports (which require drilling) and heavy-duty cast uprights. The Leitner is intentionally designed for overlanding, with storage boxes, rooftop tent mounts, fluids mounts, and even a new shower module. With all that capability, the Leitner wins our Editor’s Choice.

Value Award

While the Editor’s Choice is always a pleasure to award, it is the Value Award that helps to serve so many readers. For this, it comes down to the Front Runner and Yakima, with an honorable mention to the BajaRack. The BajaRack is one of the most rugged units in the test and sits at cab height. Their support accessories are minimal, and it is only available for the Tacoma at present. The Yakima racks have evolved rapidly in recent years, becoming excellent tools for the overland traveler, and include rooftop tents, awnings, shower systems, and brackets. And, of course, the Yakima has the best bike and boat mounts in the industry. The only issue that kept it short of the prize was a regular issue with bolts loosening and even going missing. Locknut, lock washers, and other solutions will need to be considered. This puts Front Runner as the Value Award. The platform is the best in the industry; it is lightweight and offers the most comprehensive accessory list. Trucks are the multi-tool of overland transportation, and a bed rack serves to make them even more so. (SB)

Understanding Load Ratings

Throughout this test, we make many references to the load ratings of the racks, but this is a complex and varied attribute. Unfortunately, there are no standards bodies that certify rack ratings, and there are not any universally accepted definitions for how to test or communicate the outcomes. However, we can describe them here.

Static Rating: The static rating of the rack is defined by its maximum recommended load at the highest point of the unit. This rating is on a stationary vehicle, perhaps with a roof tent attached and multiple occupants sleeping in the tent.

On-road Rating: This may also be called a dynamic rating, which is determined through a combination of a vibration table, finite element analysis (FEA), and computer modeling. The rating will also be influenced by the vehicle’s payload and attachment limits. This rating takes into consideration changes in road surfaces, bumps, impacts, and other reciprocating forces.

Off-road Rating: If the manufacturer lists an off-road rating, it will include higher force values and more stringent vibration table testing. Unfortunately, this rating is not provided by all manufacturers, but it is the most important of the test.

Factory Limits: In addition to the limitations of the rack designs, there are also constraints on the factory attachment points (often the channels mounted to the bed), OEM payload, and roof load limits. For example, Front Runner limits the dynamic load rating of the entire rack due to the Toyota accessory rail limits.

Our No Compromise Clause: We carefully screen all contributors to ensure they are independent and impartial. We never have and never will accept advertorial, and we do not allow advertising to influence our product or destination reviews.