Editor’s Note: This article was originally published in Overland Journal, Summer 2017

Click, click, click. We all know the sound, as well as the feeling that comes from having a dead battery—the starter fighting against low voltage with limited amperage to turn the motor. If you are in the parking lot at work, the fix is usually a relatively painless jump or tow. However, when traveling in the remote destinations of the globe, a battery failure can have dire consequences. The least critical outcome would be some warm beer, the worst being a disabled vehicle. During my travels, the most common vehicle maladies have been battery, charging, and electrical issues, resulting in serious frustration and at times extensive repairs. In this modern age, we rely heavily on electronics; not only to run all of our overland systems, but also to operate the numerous computers and solenoids on the vehicle.

Throughout the decades, dual-battery and separator technology has continued to improve, migrating from switches to isolators, and incorporating metal-oxide semiconductor field-effect transistor (MOSFET) arrays. The driver can now monitor the status of both (or many) batteries, and activate manual combining or separation of the various power banks. These kits are becoming increasingly simple to install, with pre-wired harnesses and often every last bolt or connector supplied. The quality has improved as well, with sealed solenoids, heavy-gauge wire, and coated terminals. For this review, we dug deep into the best available options to determine a winner.

SELECTING A DUAL-BATTERY SYSTEM

The first questions to consider are if a multi-battery setup is needed at all, and what attributes and capacities are required for the given application. For many, a high-quality AGM starting battery and a small lithium jump pack might be all that is called for. For others, there are complex accessory and house systems that necessitate multiple power sources and hundreds of amp hours of reserve. One of the simplest solutions is a fully mechanical switch that relies on user intervention to combine or disconnect the inputs. This has several advantages with regard to cost and durability, but requires a fastidious mind to make sure things don’t go flat. The next option is a semi-automatic unit that allows for remote control via a switch and solenoid, sometimes including features that combine sources once ignition-on is present. The most sophisticated are controllers that include microprocessors and logic to join or uncouple batteries based upon a wide range of conditions. Some even provide a manual or mechanical override (or both). These are the most expensive options and the most likely to fail given the complexities and electronic circuitry. All of these products have their place, but we are concentrating on automatic controllers, most of which have remote displays.

TESTING PROCEDURES

We focused primarily on bench analysis and controlled- environment monitoring. Each one was installed on the test rig and connected initially to an AGM starting battery and a lithium-ion auxiliary battery. We evaluated all factory functions and analyzed each of the fault modes for failure conditions. Monitoring included solenoid heat signature under heavy loads and total voltage drop. The extreme load evaluation was done by connecting a 3,000- watt, inverter-powered AC unit and an AGM battery with a compromised cell, resulting in a near 100-amp spike. We also performed more typical inputs like connecting a National Luna fridge. Our primary concerns were with reliability and repeatability of listed attributes. All systems ran for a minimum of 24 hours.

From this evaluation we determined a few key outcomes and considerations. One of the most important being the usability and features of the control unit. This attribute really does separate the wheat from the chaff, as all of the products have a quality solenoid as part of their base offerings. The monitor is what allows the operator to see the condition of the batteries and also activate the remote functions of the relay, like manually combining the sources for winching or jump-starting the vehicle. Some have alarms and other status indicators that help determine the state of charge for all sources, including the alternator. Our findings made it clear which systems were the most thought-out, as only a few are either truly comprehensive or include unique design elements. This comes through in attributes like MOSFET switches and thoughtfully contrived displays.

BLUE SEA SYSTEMS (Value Award)

ML-ACR Automatic

Charging Relay

PROS

PROS

Wide availability and good value

IP66 waterproofing

Manual override switch

CONS

No supplied hardware, harness, or wiring

Lack of battery level display

Blue Sea Systems has been a stalwart of the marine industry for decades, producing high-quality switches, panels, fuse blocks, and electronics that have become a standard for wiring system installations on overland vehicles. eir familiar 12-volt and USB outlets adorn all of my own projects. They have also entered the charger/isolator space with a few new variants, the most notable being their Automatic Charging Relay.

The ML-ACR is a 500-amp magnetic latching (bi-stable) dual-battery system that allows for starting isolation of the house loads, fully automatic function, and manual on/off from the supplied dash-mounted switch. Exclusive to the group, it has a manual and mechanical override knob on the top of the body that provides control with or without power; there is even a lock-off for servicing and vehicle storage.

Installation was easy and only took 15 minutes on the bench test, one cable going to the starting unit and the other to the house system. There are six signal wires, one serving as a remote for manual override, and the others a combination of power, ground, and isolation signals. In use, it performed flawlessly and quickly combined or disconnected the AGM and lithium batteries. A quality rocker switch is provided that allows driver intervention for on, off, and auto; these settings are also shown on a small schematic. The factory logic worked as expected, automatically combining loads once the starting circuit reached 13.5 volts for 30 seconds. The magnetic latching is a unique technology in this test, using less than 40 milliamps when in the combined state. Power is really only used when the magnet changes state, pulling 7 amps.

$275 | BLUESEA.COM | 800-222-7617

INTELLIGENT BATTERY SYSTEM (Editor’s Choice)

IBS-DBS

PROS

PROS

Class-leading display and controller

Status displayed for all major functions and systems

All wiring and connectors supplied

Extensive computer-controlled logic

CONS

Modest amperage capacity

Relay boost module required for heavy loads

Intelligent Battery System (IBS) GmbH is a specialty electronics engineering firm in Switzerland. They focus on mobile power systems from solar and inverters to remote mapping computers designed for the harshest conditions. Founder Beat Wyss is a passionate overlander and his experience influences every item the company produces. Their dualbattery system was introduced in 2008 and has won several awards along with the loyalty of many.

The IBS-DBS is one of the more sophisticated offerings on the market, using a micropower RISC processor to control the components. It is comprised of two modules: a relay and monitor. Also supplied is a comprehensive assortment of cables, wiring, and connectors. What makes this product different is the degree of functionality and display that is available to the driver, including manual override and fully automatic control. The voltage of the main and auxiliary batteries are both shown in LEDs along with the current charge from the input, alternator, or solar.

Installation is straightforward, requiring connection of the two main charge cables, three signal wires, and a ground. A status wire monitors both of the batteries and provides the computer with voltage conditions. The relay is smaller than that of all of the others, constructed from fiber-reinforced plastic with a single molded mounting tab. The most time-consuming part of the install is to determine the best location to mount the display for accessibility and line-of-sight to the indicator levels. Three membrane switches control all functions, including manual linking, automatic, and alarm silence. Quality weatherproof connectors are supplied for the signal wires. The last step of the install is to integrate the relay boost module to allow for higher current during link-up for jump-starting and winch use.

$379 | IBS-TECH.CH | 41-33-221-0616

NATIONAL LUNA

Intelligent Split Charge System

PROS

PROS

Complete installation kit

Extensive status indicators

Bright, easy-to-read display

CONS

The 85-amp solenoid limits winching and jumping

Harness connection on display is fragile

Display can be too bright during nighttime use

National Luna is a South African company that lives and breathes electronics made for severe-duty use. Known for their class-leading fridges, they also produce lighting and dual-battery products. We have used their 12-volt system on our own project vehicles, and they won the Editor’s Choice Award in our first dual-battery review (Winter 2008).

This is the most comprehensive kit in the test, and includes every possible connection and terminal, along with over 20 feet of positive and negative cables. Thoughtful details include two high-amp fuses and a fully assembled controller harness. This kit is made with the overlander in mind, featuring a bright and easy-to-read display and manual override to combine the batteries. The controller logic is heavily biased toward the starting battery, including a 5-minute priority charge once 13.1 volts (or more) are detected. It will also disconnect the starting battery when 12.7 volts or less are measured, isolating both banks.

The installation of the National Luna was the easiest, with comprehensive instructions and a full complement of installation parts. The Intelligent solenoid mounts near one of the batteries and is appropriate for engine compartment conditions. It also displays a few important indicators, like an active timer, solenoid engagement status, and if the internal fuse is blown. The controller installs near the driver and utilizes a pre-assembled harness. In use, this kit is feature rich and has proven to be quite reliable. The only issue we have experienced is with the connector terminals failing on the bottom of the display. The other notable concern is the continuous duty rating of the solenoid, which at 85 amps may be less than the alternator output of many modern vehicles. That rating also limits winching and jump-starting amperage.

$395 | NATIONALLUNA.COM | EQUIPT1.COM | 866-703-1026

PERFECT SWITCH

Power-Gate Dual Rectifier

PROS

PROS

MIL-STD construction

MOSFET switch

Low current loss

CONS

Higher cost

Connecting to alternator regulator can be complicated

Display and control unit not currently available

The Power-Gate is a MOSFET dual rectifier designed specifically for extreme military and field work. Perfect Switch was founded by Scott Stolper, a Land Cruiser enthusiast and backcountry explorer; his time in the field inspired the product. Years of R&D resulted in this offering, the most innovative in this review.

Essentially a giant diode, the system controls the input to the alternator anode and the output to the main and auxiliary cathodes. The presence of charging voltage opens the arrays and allows for minimal voltage loss as both batteries receive full current. Being a dual rectifier, the batteries are never connected unless the manual override is activated. This item also differs from the rest in that it is integrated to the vehicle, the input coming from the alternator, and the Power-Gate serving as a signal to the voltage regulator (for internal regulated alternators). The isolator is of extremely high quality, with a durable case and massive cable studs. It is filled with Dow Corning Dielectric Tough Gel to protect the electronics, and a four-layer circuit board controls all functions.

Installation is easy, with only a few wires and cables to connect. The system is not delivered with any wiring, cables, connectors, or switches, so they must all be sourced by the buyer. This reflects the intended military application, rather than a DIY consumer. The most complicated part of the install is to ensure that the alternator excites properly and that output only goes to the anode post. This requirement may necessitate a call to the excellent tech support staff at Perfect Switch. There are several integrated LEDs, including power and fault status for both outputs. There is also a blown fuse and excite LED. They are working on two styles of display and control units that will be available before the end of 2017.

$433 | PERFECTSWITCH.COM | 858-720-1339

PAINLESS PERFORMANCE

Waterproof Dual Battery Current Control System

PROS

Good value

Waterproof construction

Quality components

CONS

No logic control

Risk of user error

Limited status indicators

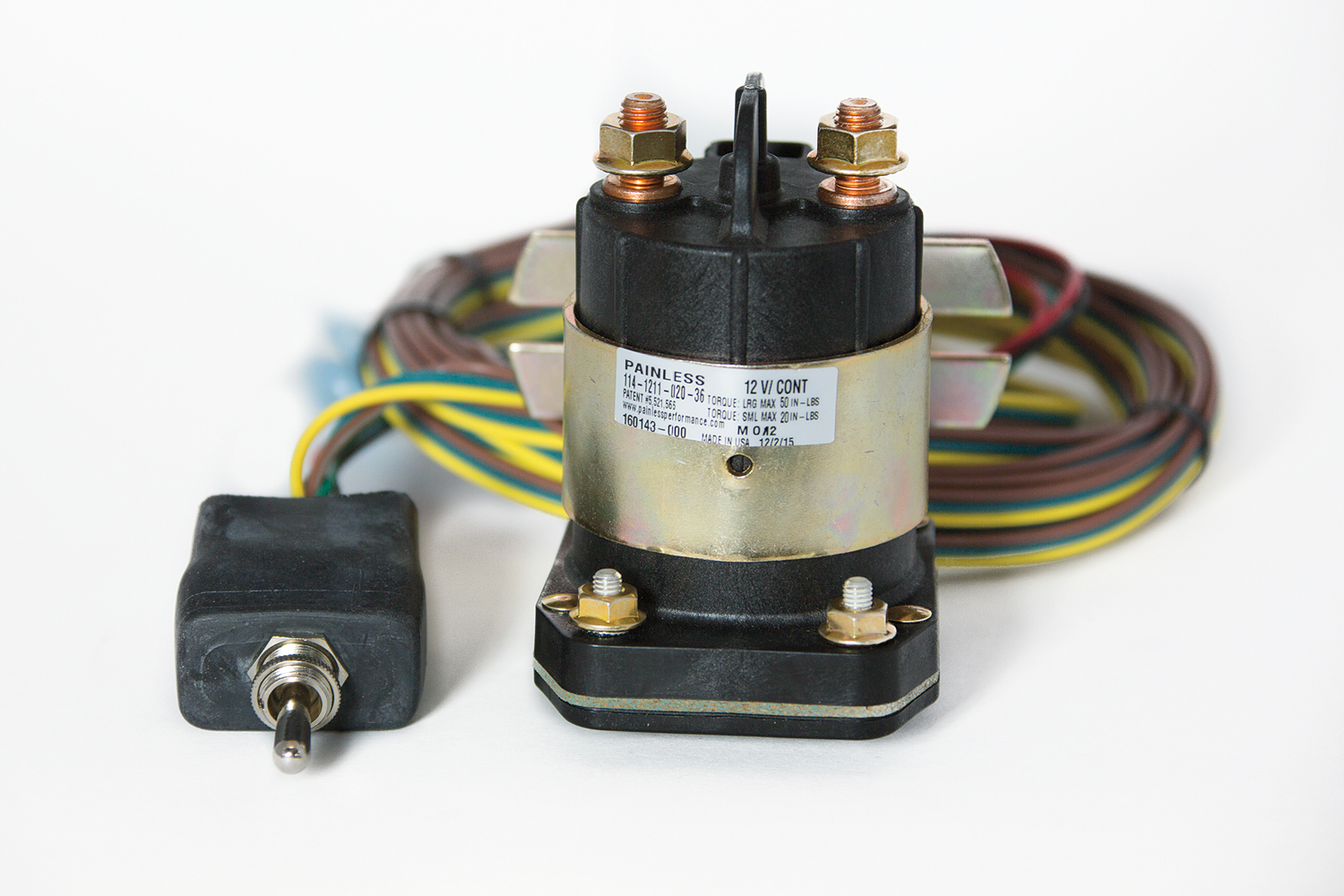

Painless has been around forever; my earliest memories of the brand being a fuse block and harness for my 1953 M38A1 Jeep. Their entire lineup is designed and made in America, and they have a long history of supplying harnesses for vintage vehicles and other applications. Their electronics are known for production quality and easy-to-identify wiring labeling and colors that improve serviceability and repair. This particular item is no different, and ships as a nearly complete kit.

This was one of the more elementary systems, eschewing new technologies and even a basic display. It relies on a heavy-duty 250-amp mechanical solenoid/relay, harness, waterproof three-way switch, and two LEDs. Position one isolates the auxiliary battery and turns off the LEDs. Position two connects the auxiliary only when the ignition is on, activating a green LED. Position three keeps the main and auxiliary batteries connected at all times, displaying a red LED. It is a somewhat hybrid system, with the only semi-automatic function being key on. I see it as more of a remotely controlled separator, which is often what people want. However, the real risk comes with forgetting to disconnect the house system and draining starting voltage.

Installation is slightly more time consuming than the others, with most of the components and connectors supplied, excluding the main cables (reflected in the price). The heavy-duty solenoid can be mounted in any position and is waterproof, and the body is constructed from fiber-reinforced plastic. The switch and LEDs install within reach of the driver and take minimal real estate. This is a robust system, but it lacks any logic control, so the fate of the batteries is squarely in the operator’s hands.

$263 | PAINLESSPERFORMANCE.COM | 817-244-6212

Conclusions

Testing dual-battery systems may seem as exciting as a trip to the dentist, but this evaluation has shown that there are only a few leading contenders in the field. We considered over a dozen different units and ended up with five of the most popular on the market. For our Value Award, it came down to the National Luna and the Blue Sea ML-ACR systems. Both have their advantages. The NL is the most comprehensive DIY kit in the review with every last cable and part needed for installation. It is also feature rich with a remotemounted monitor. The negatives are primarily focused on the limit amp capacity of the solenoid for winching and jump starts. The ML-ACR is not only high-capacity, but also has low draw with the magnetic latching relay. This makes parasitic loss one of the lowest in the test for both open and combined states. I also appreciate the manual override switch that allows for a mechanical disconnect of the auxiliary battery. The installation is simple and includes a quality (and discreet) rocker switch. These factors and the low cost earn the Value Award for the Blue Sea ML-ACR.

The Editor’s Choice Award also came down to a head-tohead, in this case between the Perfect Switch Power-Gate and Intelligent Battery System units, solutions unique in the field but for different reasons. The Power-Gate is a MOSFET switch that provides the highest standards of durability and low voltage loss. It is produced from high-quality materials designed to endure the most extreme conditions found in military and commercial applications. As a result, it is expensive and also lacks features (like a monitor) found on consumer models. A display and remote control is planned for the future, but was not available during our evaluation period. The IBS model is one of the most comprehensive in the test and was delivered with cables and heavy-duty battery post terminals. The relay is compact and of sufficient capacity, allowing 200 amps under continuous use. The control unit displays the condition of both sources and the alternator charging voltage. Manual linking and an alarm are also possible to initiate from the display. Given the thoughtful design and wealth of functions, along with a decade of proven performance, the IBS gets our nod as the Editor’s Choice.