Editor’s Note: This article was originally published in Overland Journal, Gear Guide 2015.

Air, the simple mixture of nitrogen, oxygen, argon, and a few other gases, is not only elemental to life, it is a fundamental requirement for a vehicle or moto-based backcountry trek. In addition to assisting our internal combustion engines in converting chemical energy into thermal and mechanical energy, it also, under pressure, allows our tires to support the weight of our vehicles and achieve optimum performance in a variety of conditions. When compressed and stored, air can be used for a number of tasks from the banal to the bizarre: inflating an air mattress, powering pneumatic tools, cleaning parts, reseating the bead of a tire, and even spooling up a blender of frothy margaritas. For these reasons, we’re delving into the best options for compressing, managing, and dispensing this overlanding requisite. We can’t see it, taste it, or touch it, but without air…our margaritas could be a bit on the rocky side.

Like many of you, I became aware of the need for an air compressor during one of my first four-wheel drive trips. At the trailhead, a member of the group kneeled down and started letting the air out of his tires. I looked around to see if he was alone in this perplexing act; he was not. If I were quick on the draw I would have said something semi-intelligent, like, “What air pressure do you like to run?” Instead, I blurted out the first thing that came to mind, “Why are you letting the air out… where do you fill them back up?” He said, “I have an engine-air pump,” and produced a long hose with a valve stem chuck on one end and a nifty little piston thingy on the other. Simply pull out a spark plug, insert the high-tech gizmo, crank up the motor, and pump up your tires—albeit painfully slow. I purchased one as soon as I could afford the $25 price tag. A few years later a friend showed up on a run with an engine-mounted, belt-driven compressor. It was an air conditioning compressor plumbed to pump air rather than Freon—another marvel of ingenuity. Monday morning I headed to Pick-n-Pull, and the spark plug thingamajig went into the trash.

In the mid-’80s an array of inexpensive 12-volt compressors began to appear on the shelves of discount auto parts stores. The quality of most was marginal at best, but in the early ’90s a number of dedicated 4WD aftermarket companies started offering products that actually worked. The evolution of these products has resulted in some highly effective vehicle-based and portable air options.

In addition to inflating tires, a good air source will provide two key services: reseating tire beads and running air tools. Although spraying a shot of ether in an unseated bead and lighting a match does work, this method is very dangerous, can be downright scary, and is not suggested. A compressor or air tank is more reliable and much safer.

Reseating a tire bead: I’ve found the second most common use of an air compressor is to reseat a tire bead. During a jungle trek to Angel Falls, Venezuela, our group peeled the beads off of seven tires in the first 24 hours. We had a single, beat-up, 15-year-old ARB compressor. It didn’t produce a high volume of air, but with careful manipulation of the tires it did the job. If you spend much time on the trail, the ability to reseat a tire bead should be a consideration when sourcing a compressor.

Pneumatic tools: A few of you may be scratching your heads at this one, but I can tell you that pneumatic tools on the trail are beautiful things. I’m not referring to impact wrenches (I can spin a spanner by hand), but rather die grinders and drills. On dozens of occasions someone in my group (or someone I’ve met stranded on the trail) has broken a spring perch, shackle, frame, or bumper mount. In this situation, pneumatic tools and a welder are a godsend, but air tools need a lot of air. For this type of trail repair you will also need an air tank.

Belt-driven compressors are an excellent option for extended overland travel, but they have their drawbacks. The challenge with belt-driven compressors is that real estate on the front of the motor is limited, and sacrificing a luxury item such as air conditioning is often required. Another option is a portable source such as the Power Tank. The Power Tank can’t be beat with regard to the volume of air it can produce. It can be trotted from vehicle to vehicle, airs up tires in seconds, and spins pneumatic tools like you are working in a shop. However, they too have drawbacks: their contents are finite, refills come at a cost, and sourcing a shop to dispense refills can be difficult if not impossible in some areas. This leaves us with electrically powered 12-volt options. They are readily available in a wide range of performance levels and costs.

Considerations

Heat dissipation: The mechanics of compressing air is one of physics. In the case of a 12-volt compressor, we convert electrical energy stored in a battery to mechanical energy via the air compressor’s motor and attached piston. That system converts mechanical energy back into stored and thermal energy (compressed air and heat). The thermal energy created is a byproduct of friction and the isochoric process of compressing gas within a closed, or constant-volume system. Some of the thermal energy created is expelled through the air hose, but a fair portion is absorbed by the compressor’s components, which become heat sinks. Heat buildup can be a compressor’s nemesis. It can damage components, reduce performance, and if not managed effectively, will ultimately cause the system to fail. Some compressors have thermal-protection circuitry that will automatically shut the system down if it reaches a certain temperature, and then restart it when it cools to safe operating levels. Others have a manual reset button.

Duty cycle: Duty cycle is the amount of time a system can be active versus the amount of time it must be inactive. For example, a system with a 100-percent duty cycle can run continuously at a given psi (resistive pressure) and ambient temperature, whereas a compressor with a 50-percent duty cycle will operate only half of that time under the same conditions. This sounds simple, but that cycle can be over a period of 10 seconds, 10 minutes, or 10 hours, temperature and psi can vary, and there isn’t an industry standard defining how duty cycle must be tested/advertised. Duty cycle is not a vital consideration if you are inflating a single set of tires, but if three or four of your buddies line up behind you, it could become an issue. Additionally, if charging an air tank to run pneumatic tools is in your future, your compressor will need to run continuously to keep up with demand.

Output: As is the case with the duty cycle, compressor manufacturers can massage performance data (measured in cubic feet per minute (CFM) or standard liters per minute (SLM) by adjusting testing criteria. The International Standards Organization (ISO) does set parameters, but those parameters do not seem to be required with regard to advertising. Variables that can affect these values are ambient temperature, input voltage, and resistive backpressure. Thus a unit that generates 3 CFM at 20 psi may only produce 1 CFM at 90 psi, with all other factors being equal.

Testing Procedures

Tire Inflation

The tire inflation test consisted of filling a 33-inch and 35-inch tire four times each; duration, amperage draw, noise levels, and input voltage was recorded.

Our initial test simulated the demand put on a compressor during a typical day on the trail—first airing up your own tires, then your buddy’s tires. Test subjects were a 33×12.5R15 Pro Comp XTerrain and 35×12.5R15 Mickey Thompson Baja Claw, which were inflated from 15 psi to 35 psi alternately (deflating one back to 15 psi as the other was inflated) until we had made four passes on each. We recorded the time to inflate, amperage draw, maximum cylinder head temperature, and noise levels (at arm’s length). Vibration, though we had no way to quantify it, was also noted. A pair of vehicle-mounted Odyssey batteries powered all units.

The engine was left running to maintain proper voltage: approximately 13.8 volts, though this varied slightly with amperage draw. We used Viair’s digital air gun to confirm high and low pressures for all units with standard NPT pneumatic fittings. For units with thread-on chucks and in-line gauges, we predetermined the gauge error (these were off by 5 to 6 psi). The equipment used for testing were a Klein Tools True RMS CL2000 clamp-style amp meter, Ideal multimeter, and a Radio Shack decibel meter and infrared thermometer. Compressors were not turned off for the duration of this test, and inflation times were averaged.

Reseating a Bead

For this task, we unseated the bead on the 33-inch tire and mounted it back on the vehicle. We then applied a liberal amount of soapy water to help create a seal, attached the air chuck, and attempted to set the bead like our lives depended on it (as they might on the trail). Short of carrying a Cheetah bead seater (bulky) or a can of ether (dangerous), this is how it’s done. This was a pass or fail test.

Pneumatic Tools

To access how units would perform as an air source for running pneumatic tools, we plumbed each compressor to the tank on my ’82 Hilux (approximately 3 gallons), charged it to 90 psi, and used a die grinder to cut through a .125-inch steel plate 2-inches wide (simulating a vehicle frame). During the charge-up period we evaluated high-pressure performance by measuring the amount of time to raise tank pressure from 50 psi to 90 psi. Each product was allowed 30 minutes to complete the task and a score was given based on the percentage of completion. One compressor, which has an onboard tank, was run with the auxiliary tank configuration and as a stand-alone unit.

Duty Cycle

To assess duty cycle we fitted each unit to a 25-gallon shop compressor tank fitted with a pressure regulator, which maintained a constant resistive force, and ran it at its advertised time and pressure. During this test, we measured amperage draw, maximum head temperature, and noise levels. Ambient temperature was 68°F and data was collected every five minutes. Though all products performed as advertised, the wide range of criteria rendered an apples-to-apples test impossible. Emphasis would be placed on actual field and lab performance.

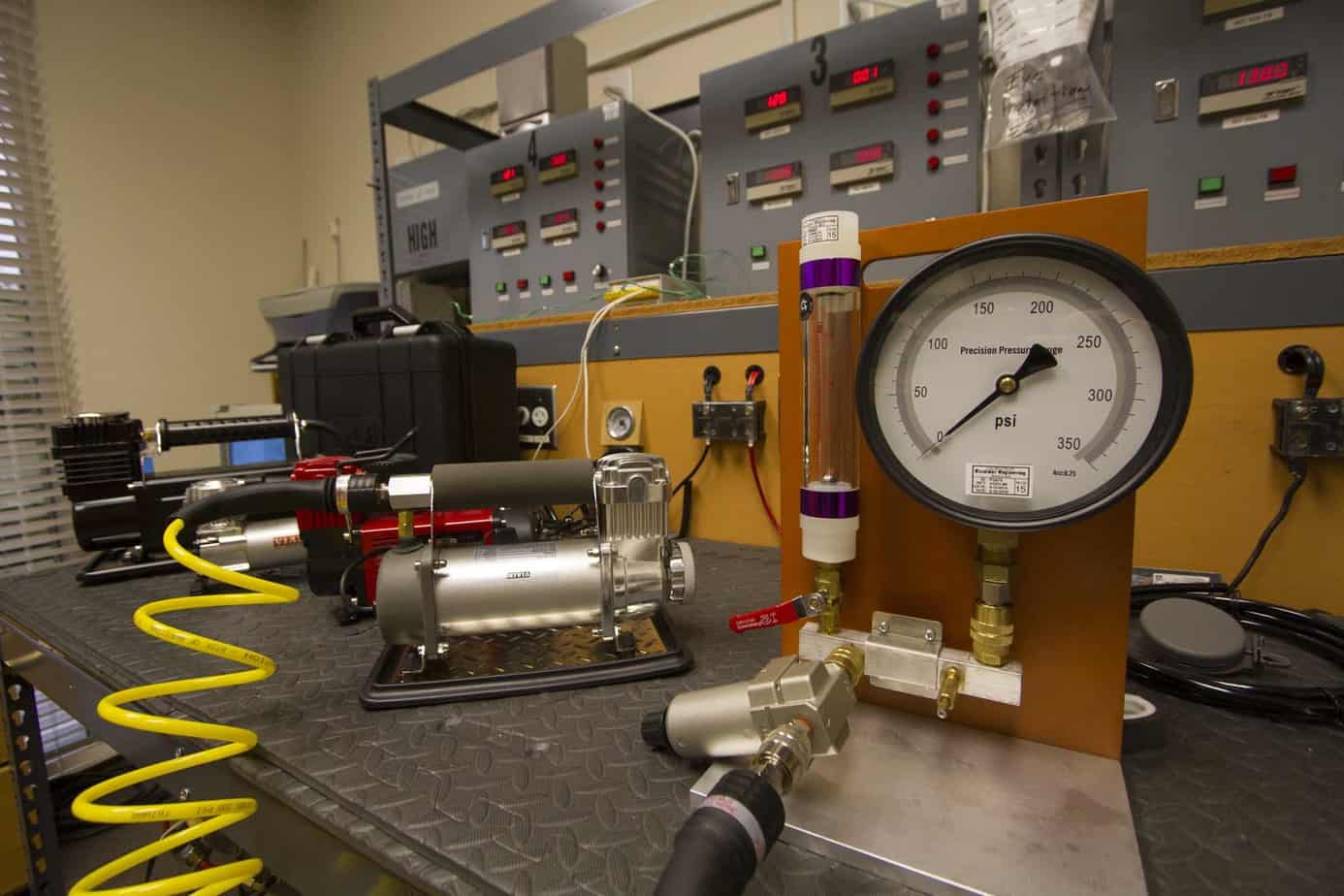

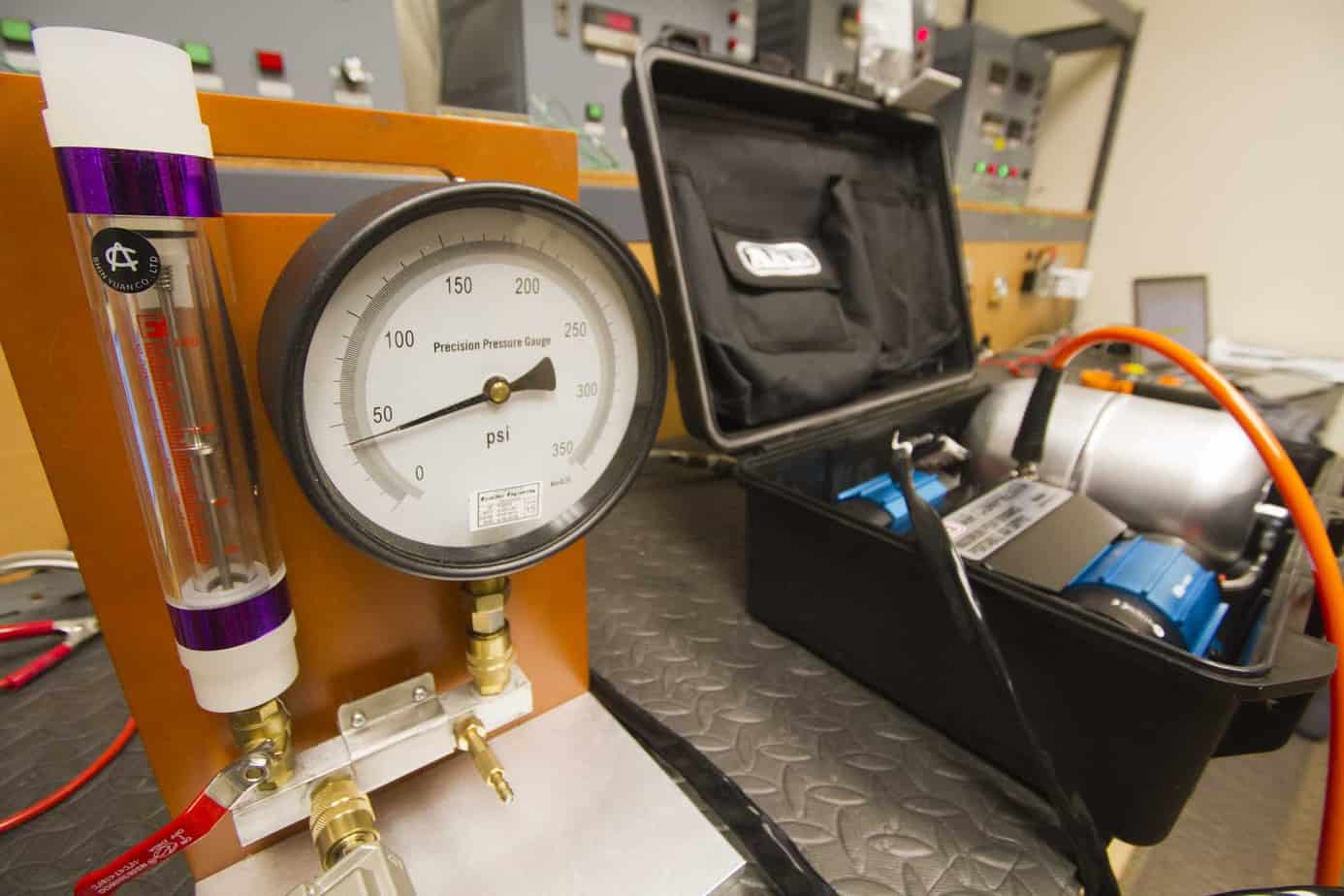

Below: Field data was recorded with Klein Tools True RMS CL2000 clamp-style amp meter, Ideal multimeter, and a Radio Shack decibel meter and infrared thermometer.

Lab Testing

Viair was kind enough to allow us the use of its lab in Irvine, California. To measure true airflow, or CFM, at various resistive pressures, we fitted each unit to a mass airflow meter. Three pressure levels were set at zero, 40, 60, and 100 psi, and again at their maximum advertised pressure. Data was collected for CFM and amperage draw.

Depending on your individual needs and budget, a high-dollar compressor may be overkill and a strain on your kid’s college fund. The important thing is to purchase one that is reliable and will hold up to your individual demands. Products in this review are from ARB, Viair, Smittybilt, and Q Industries. We pushed this test back six months in hopes of including Extreme Outback Products’ new portable, but it was unfortunately not available as of our final Gear Issue deadline. Warn has discontinued their air compressor line, Sun Performance is no longer in business, and we contacted Air-Zenith but they chose not to participate.

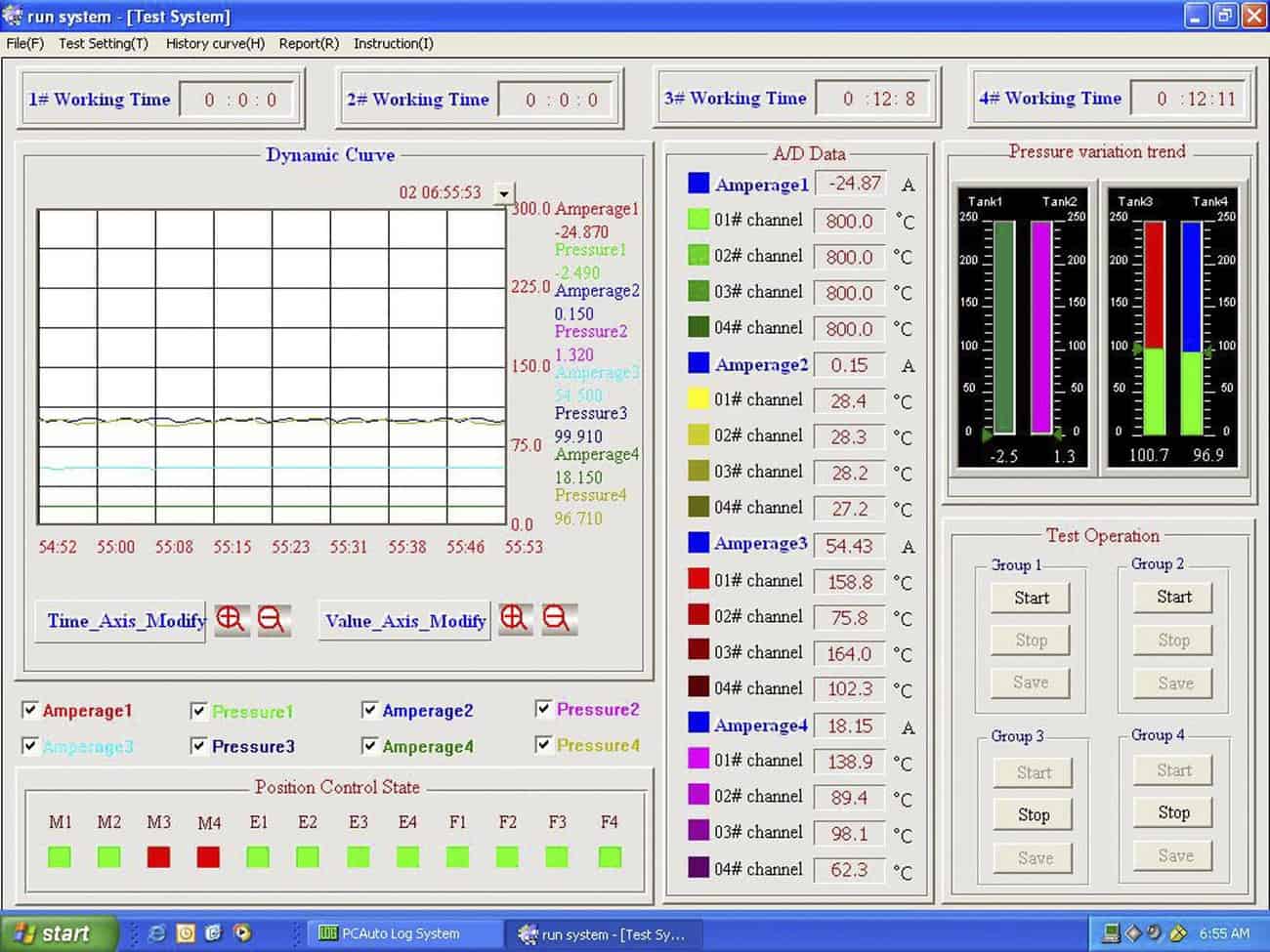

Below: We used Viair’s proprietary analytics software and four-probe thermal system to determine performance and thermal management at various operating pressures.

Individual Product Reviews

Q Industries SuperFlow MV50 $74

The SuperFlow MV50 has been around for years, and in that time has raised a fair amount of discussion amongst the airhead crowd. As the least expensive unit in this comparison, and with online forum comments ranging from cheap to amazing, we needed to find out at what level this low-dollar option is appropriate for overland travel. Build quality, finish, and components are what we’d expect for a budget import option. The kit includes a carrying case with quick-release buckles and a separate pocket for the light-duty air hose, but it is very light-duty and would probably need to be replaced with any regular use. There is a rubber-coated carrying handle above the cylinder head, which doubles as protection for the 150-psi gauge. Interestingly, the gauge face is printed with a disclaimer of a deviation of plus or minus 10 percent (gauge accuracy was found to be 82 percent at 35 psi). Fittings are NPT, which will allow use with any standard pneumatic fitting.

Above: The MV50 kit includes a carrying bag, 16-foot coil hose, and inflation kit.

The on/off switch is on the end of the motor and is covered with a clear plastic cap that seems fairly well sealed. The unit does not have an automatic pressure shut, nor does it have a pressure relief valve. It also lacks a reset button. If it shuts down, check the fuse and let it cool for 20 minutes. Battery cables are a reasonable gauge, have an in-line 30-amp automotive-style fuse, and large, plastic-covered clamps. There is a rather flimsy plastic filter on the cylinder head, but it should be removed when the unit is stowed to avoid damage.

Below Left: The air gauge, filter, and output fitting mount directly to the cylinder head. A rubber-coated handle allows for carrying when hot.

Below Right: Components are stored in a light-duty canvas bag with a separate pocket for the 16-foot coil hose.

The manufacturer states the MV50 will fill a “full-size truck tire from 25 psi to 35 psi in less than three minutes.” However, reducing pressure to 25 psi will provide little benefit on the trail. In our more realistic exercise it actually performed better than advertised, 3 min. 27 sec. for the 33-inch tire and 4 min. 23 sec. for the 35-inch tire. Current draw was 21.65 amps and head temperature peaked at 221°F. During this test, we noticed a knocking sound (like a rod knock) but it didn’t present itself as a problem during testing. It took no issue when reseating the tire bead, and motivated the die grinder through 56 percent of the .125-inch steel plate in the allotted 30-minute time. In the lab, the MV50 produced 1.41 CFM at zero psi (far short of the advertised 2.54 CFM), but was reasonably consistent through the 60-psi range. The manufacturer indicated a 50-percent duty cycle but does not state the ambient temperature or resistive pressure. I didn’t expect much from this economy import, but it did very well in all categories. Made in China. northerntool.com, 800-838-0516

Pros

- Cost

- Uses NPT fittings

- Includes carrying case

Cons

- Flimsy carrying case

- Internal knocking sound

- Gauge inaccurate

Below: The MV50 uses standard NPT fittings, has a thread-on valve stem chuck, and light-duty but insulated battery leads.

Viair 88P $70

The 88P is Viair’s entrant into the economy throw-a-compressor-in-your-truck-just-in-case market. Having said this, the quality of construction seems reasonable. A comfortable plastic handle spans between the cylinder head and output module, power leads are suitable for its 20-amp maximum current draw, and battery clamps, though a bit small, are fully insulated, have a grippy feel, and are of good quality. A 120-psi gauge is permanently mounted to the output module, though it was off by 5 pounds at 35 psi. The on/off switch is on the motor end cap but it lacks any type of weather protection. As with the SuperFlow unit, the 88P doesn’t offer an on/off cutoff or pressure relief valve.

Above Left: A tough and inexpensive lightweight compressor option, the 88P is well built and has a quality feel.

Above Right: The unit rides on rubber insulators to reduce vibration and has an integrated handle that stays cool.

Battery leads are 9 feet in length and the air hose is 12 feet, enough to reach around most vehicles but probably not to a trailer. Unfortunately, the air hose is directly plumed into the compressor (rather than with an NPT fitting), which excludes the option of replacing it if damaged, and eliminates the possibility of filling an air tank to run pneumatics. I would probably opt to splice in an NPT fitting to the provided line to allow the use of a proper clip-on tire chuck. A carrying case is not included, but the handy little LED work light on the handle would be helpful at night.

Above: A built-in air gauge (though inaccurate by 5 psi), integrated air hose, LED light, and on/off switch ride on the output end of the compressor.

With a price point of $70, we didn’t expect the 88P to keep up with the higher cost units. Inflation rates, at 5 min. 15 sec. and 6 min. 57 sec., were the slowest in the group. Maximum operating temperature, at 205°F, was among the lowest, and it sipped a mere 15.95 amps. Noise levels were average and vibration was not excessive. Seating the tire bead didn’t break any time trial records, but the 88P chugged away and got the job done. I was quite impressed considering its diminutive size and low output volume. Due to its thread-on tire chuck and integrated air hose it was unable to participate in the pneumatic tool or duty cycle exercise.With regard to true output, lab results (1.09 CFM at 40 psi) were lowest in the group. However, it was again the coolest, lightest, quietest, and drew the least amps. The 88P doesn’t boast of being a tornado-inducing dynamo, but rather an inexpensive and reliable option for airing up a tire; it is just that. Made in China. viaircorp.com, 949-585-0011

Pros

- Cost

- Compact and lightweight

- Good construction

- Low amperage draw

Cons

- Low output

- Gauge inaccurate

- Limited to tire inflation

Below: Battery leads are insulated and of reasonable quality; tire chuck is the thread-on type.

Smittybilt 2871 $150

In the past decade Smittybilt has focused on offering a price point option for nearly every category in the four-wheel drive market. Though the 2871 is physically as large as the full-size units in the test, it carries a price tag of only $150. It comes in a light-duty canvas bag that has sufficient room for cables, an air hose, and accessories. However, I’d probably not add much to the 15.5-pound burden of the compressor. The 2871 has a solid feel, and construction of the base unit appears to be good. It is mounted via rubber anti-vibration posts (or insulators) to a base platform. A perforated metal handle spans between the cylinder head and output module, and on one end is a brass pressure release valve. A thermal cutoff switch protects the motor from overheating, and a reset button rides on the end of the motor next to the on/off rocker switch. The weatherproof rubber switch cover on the unit was partially dislodged but we were able to remove the switch and properly seat the cover without issue. Battery leads are of reasonable quality, have insulated alligator clips, and are 8 feet long.

Above: The Smittybilt 2871 comes in a canvas bag and includes a 24-foot coil hose.

Concerns began when we attempted to hook the quick-release fitting to the test system. For some reason, Smittybilt chose a non-standard air fitting rather than the ubiquitous NPT. In an attempt to adapt the unit for the test I wasted half a day at various air tool shops. The common response was, “Never seen one of those before.” If you buy this compressor, save yourself some grief by cutting the feeder hose off and install a proper NPT quick connector, new air hose, and valve stem chuck. The problem with a non-standard connector is that if it fails in the backcountry, you’re up the creek (trail) without a compressor. We also found the gauge to be off by 6 pounds at 35 psi; it’s not an issue if you throw the hose away and convert the system to NPT. The manufacturer states the duty cycle to be 66 percent at 40 psi (40 min. run time with a 20 min. cool down).

Above Left: The Smittybilt 2871 comes in a canvas bag and includes a 24-foot coil hose.

Above Right: The tire chuck is a thread-on style and the filler hose has an in-line gauge.

Inflation times were in the middle of the pack at 3 min. 44 sec. and 4 min. 47 sec respectively. It drew 37.7 amps and had a maximum head temperature of 261°F, and noise levels of 86 decibels. Vibration was considerable, enough for it to dance off our test table; the plastic air filter cover, which sets directly on top of the cylinder head, popped off and could not be reseated. The Smittybilt reseated the tire bead without issue, but it only completed 19 percent of the grinding exercise. After the first pass it took the remaining time, about 29 minutes, to recharge the tank. At higher pressures (50 to 90 psi) it was painfully slow. Though nowhere near the advertised output of 5.65 psi, lab results were good (2.72 and 2.22 CFM at zero and 40 psi respectively) though it faded off steeply at maximum pressure. Made in China. smittybilt.com, 888-427-2872

Pros

- Cost

- High output at lower pressures

- Includes carrying bag

Cons

- Non-standard air fittings

- Excessive vibration

- Air filter popped off

- Carrying bag is light duty for weight

- Steep decline in output at maximum pressures

Below: A weatherproof on/off switch and reset button sits on the end of the motor housing.

Viair 400P-A $250 Value Award

Viair is a worldwide household name in the air compressor segment for good reason; they’ve been providing the commercial, automotive, and military industries high-quality, reliable products since the late ’90s. The 400P-A is a good example of a product that has weathered the storm of competition, and they recently revamped it with an automatic shut-off feature.

Above: The 400P-A is a well-constructed kit that includes a durable canvas bag, air gun, and 35-foot coil hose.

They call their carrying bag “deluxe,” and it is. It is crafted from sturdy canvas, has a quick release cover flap, quality zippers, separate pocket for the air hose, and two Velcro-sealed side pockets. In one pocket are comprehensive instructions that include operating, troubleshooting, and maintenance suggestions. The cast metal thread-on air filter is a dual-element design and comes with two sets of replacement inserts. All components invoke a feeling of confidence and are of superior construction. The unit rests on four rubber insulating posts, or feet, that are attached to a wide diamond-plate sand tray. Air exits on the opposite side of the unit from the cylinder, and a cushy foam handle insulates the user from vibration and heat. The on/off switch is a commercial-grade sealed unit, and battery clamps and cables are of equal quality. There is a 40-amp in-line, blade-style fuse on the power cord.

Above: The air hose is a high-quality, 200-psi coil type with insulated NPT couplers. Battery leads have sturdy insulated alligator clamps.

Internal electronics include a factory preset cut-off on/off switch that maintains a line pressure of 115 psi to 145 psi. This feature, which worked perfectly, allows for short cool-down periods between air-up duties. It also features thermal-overload circuitry that automatically resets when the temperature drops to operable levels. It comes with a durable 35-foot, 200-psi hose fitted with high-quality NPT quick disconnects. Anticipating the heat associated with compressing air, each end has a heavy-duty insulated heat shield…a nice touch. The 400P-A also includes Viair’s tire gun kit. This handy little unit has an in-line rubberized 200-psi gauge, sturdy rubber hose, and quick-connect valve chuck; when inflating tires simply release the trigger and the gauge indicates tire pressure. Another nice feature, as is the case with the other Viair units, is the use of roller bearings (rather than bushings) on the motor and piston rod.

Above Left: Viair’s inflator gun features an accurate 200-psi gauge and clamp-on valve stem chuck.

Above Right: Attention to detail includes a vibration-resistant diamond plate base and a quality metal air filter with two replacement cartridges.

The 400P-A was the second fastest in the inflation test, filling the two tires in 2 min. 44 sec. and 3 min. 36 sec. Current draw was a reasonable 22.3 amps, maximum head temperature was 241°F, and noise levels, at 79 decibels, were amongst the lowest. Vibration was minimal. This unit ranked second with regard to the ease of reseating the tire bead, just behind the ARB Twin Portable. It also powered the die grinder through 84 percent of the steel plate in the 30-minute window; again, second to the ARB. Lab results were respectable as well. It was right in line with the Smittybilt at lower resistive pressure, but was much more consistent through the various pressures tested. This included maintaining 1.05 CFM at a maximum operating pressure of 145 psi. Made in China. viaircorp.com, 949-585-0011

Pros

- Quality components

- Fast inflation times

- Good high-pressure performance

- Quiet

- Heavy-duty carrying case

Cons

- Lacks 100% duty cycle

Viair 45055 ADA $390

Viair’s 45055 ADA is the only compressor in the test that is not a dedicated portable unit. We included it because of its 100-percent, or constant duty rating (at 100 psi), bulletproof design, and internal electronics. This unit is compact and solid, and picking it up is akin to grasping an ataxite iron meteorite. However, it’s more than just a celestial hunk of iron and nickel. The small internal tank is wrapped in extruded aluminum capped by machined-aluminum end caps, and the piston cylinder looks like it should be on a high-performance RC aircraft. Mounts are chrome-plated steel, have anti-vibration pads, and all pneumatic fittings are industrial quality. Delphi electrical leads are wrapped with an abrasion-resistant insulated sleeve, and connections are weatherproof automotive grade.

Below: The 45055 ADA includes a wiring harness, air hose, air gun, and accessory kit.

The kit includes a premium 30-foot coil hose, spare cartridges for the air filter, and Viair’s new digital 200-psi shop-style inflator gun, which allows for the selection of psi, bar, kg/cm, and kPa. I’d advise not using the hose on a compressor with direct output from the cylinder head, as it is not suited for high temperatures. We found this out the hard way. The pressure cutoff switch functioned perfectly, regulating line pressure between 85 and 105 psi. Safety features include a pressure cutoff switch, air tank drain cock, over-pressure release valve, and thermal protection circuitry.

Below Right: The remote-mount plastic air filter includes two dual-element replacement cartridges.

Below Left: The wiring harness has an abrasion-resistant sleeve and 40-amp in-line fuse. The pressure release valve and NPT output coupler attached to a beautifully machined aluminum air tank cover.

Built to run indefinitely at 100 psi, this is not a high-output compressor. It was the second slowest in the tire inflation exercise, taking 4 min. 44 sec. and 5 min. 13 sec. respectively for the two tires. The positive side of this is that the 45055 was the smoothest, coolest, and quietest unit in the group. Head temperature, which peaked at 201°F during the tire inflation test, was the lowest in the group, as were noise levels, at a relaxing 75 decibels. Seating the tire bead was successful, though a bit on the slow side. When matted to our test tank the 45055 raised the pressure from 50 psi to 90 psi in 3 min. 39 sec. (middle of the pack) and provided enough oomph to cut through about 68 percent of steel plate in the 30-minute window. Interestingly this was the only compressor that held up to its advertised CFM claims (1.66 CFM) Though lab results didn’t break any records, the 45055 had one of the lowest falloff rates, as a percentage, at higher pressures. Made in China. viaircorp.com, 949-585-0011

Pros

- Excellent construction

- Minimal noise and vibration

- Thermal protection

- True 100-percent duty cycle

- Digital air gun

Cons

- Cost

- Flimsy plastic air filter

- Low output

Below: Viair’s new digital air gun features a clamp-on valve stem chuck and lighted display. The 30-foot coil hose is fitted with premium brass NPT couplers.

ARB CKMTP12 $875

It is overwhelmingly evident that ARB put a lot of time and consideration into the development of the CKMTP12 Twin. From the purpose-built weatherproof carrying case to the industrial-quality battery clamps, it exudes rugged quality. Though it may appear as if two of ARB’s single-piston units were simply matted together, further inspection reveals significant engineering considerations and attention to the little details that make a difference in the backcountry.

Above: The ARB CKMTP12 is packaged in a heavy-duty weatherproof case with sturdy, one-piece aluminum latches and a pressure valve for air travel.

Each of the two water-sealed motors feature hard-anodized cylinders and Teflon impregnated carbon fiber piston seals, real roller bearings and ball bearings (rather than bushings), and a linear brush preload system for extended life. The key to the “twin” aspect is a carefully designed cooling system that allows the unit to operate in ambient temperatures that will both boil water or turn it into an ice cube. Each unit has a thermal cutout protection switch, and a pressure cutoff regulates tank pressure between 135 psi (on) and 150 psi (off). There is also a 180-psi over-pressure safety valve in the case of switch failure or the operator connecting it to an external high-pressure source.

Above: The twin compressors feature hard-anodized cylinders, Teflon impregnated carbon fiber piston seals, and a linear brush preload system for extended life.

The Pelican-style case is military grade, has one-piece aluminum latches, is fully weatherproof, and has an equalizer port for air travel. Though the case and components are bulky and heavy (33 pounds), the kit will actually float. All internals are securely fixed in place and there are handy pouches on the lid for the air hose and accessories. An illuminated rocker switch and quick-release NPT connector ride between the compressors and the 4-liter aluminum air tank. The kit includes a high-quality 20-foot, 200-psi straight hose (which I prefer to a coil hose), air gun, and 7-foot battery leads with a durable protective sleeve. ARB states this unit will function, albeit at a lower duty cycle, at 212°F and down to -15°F. We used its brethren (ARB’s single) in temperatures down to -30°F during the Antarctica leg of Expeditions7 and can attest to this lower threshold.

Below: Insulated battery leads, large alligator clamps, and a 20-foot air hose are all premium quality.

This compressor was an animal when it came to inflating tires. Times were so short we had a hard time keeping up with data collection and deflating the next tire: 1 min. 36 sec. and 2 min. 1 sec. respectively for the two tires. This is in part due to the onboard air tank, which will fill while you move from tire to tire. The cost of these impressive figures was a current draw of 53.4 amps, 90-decibel noise levels, and high cylinder head temperatures. The tank is a big benefit when reseating a bead; our test tire literally jumped onto the rim in less than 15 seconds. When it completed the die grinder exercise in 21 min. 50 sec. (the only unit to complete the task), we reran it again as a stand-alone unit—it shaved more than 9 minutes off its original time. It also charged the tank from 50 to 90 psi in a blistering 1 min. 41 sec. Maximum temperature was 268°F, the highest in the group. In the lab, it was 32 percent higher than the closest competitor. These figures definitely contributed to its success in the tire inflation and die grinder tests. In the end, I was nothing less than impressed with this 33-pound, pick-up-and-carry mobile shop. Made in Australia. arbusa.com, 866-293-9083

Pros

- Premium construction

- High volume output

- Weatherproof case

- 4-liter tank

- Excellent high-pressure performance

Cons

- Weight and size

- Cost

- High current draw

- Runs hot

Below: An NPT coupler and lighted rocker switch sit between the compressors and a 4-liter aluminum air tank.

Conclusions

Though we didn’t expect much from Q Industries’ MV50, its inclusion was based on the fact that is widely used and very inexpensive. I quite honestly expected it to seize up at any moment, but it just rattled along like a trooper, inflating tires and setting beads without complaint. It even bit off a good chunk of the pneumatic die grinder exercise. Performance in all tests—output, head temperature, and amperage draw—was in the middle of the pack, and while I might not pack it for a trek to Central America, I was quite impressed with this low-buck import.

The 88P, Viair’s price point offering, struggled, as anticipated, to keep up with the higher cost units. Though it didn’t set any time trial records inflating tires, was not suited for the pneumatic tool test, and output dropped of severely at maximum advertised pressure, it was able to reseat the tire bead, was quiet, and reliable. And construction, while not to the level of Viair’s performance compressors, is good. This would be a reliable, low-cost, toss-in-your-trunk option for a second vehicle—I’ll probably put our test unit in my wife’s Toyota 4Runner.

The Smittybilt 2781, at $150, falls in the middle of the cost category. Though it didn’t support its “most powerful compressor in its class” claim, inflation times, current draw, and noise levels were in the middle of the pack, and it reseated the tire bead easily. However, it gravely struggled with output at higher psi, falling off steeply at above 100 psi. The fact that it comes with non-standard air fittings is a big deal, and not acceptable. Other concerns were the air filter cap popping off, inaccurate gauge, and a dislodged cover on the switch. The unit ran just fine throughout the test, but a few attention-to-detail items could definitely use a revamp by the manufacturer.

Value Award

The Viair 400P-A has been a standard go-to compressor for a number of years. In our spring 2008 comparison it received the Value Award for good reason. It is solidly built, runs cool, is quiet, and performed near the top in all categories. The canvas carrying case is durable and suited for long-term use, pneumatic hose fittings are high quality, and Viair’s air gun is superior when it comes to inflating tires. For these reasons, though it was edged off of the Editor’s Choice podium, it is a worthy, reasonably priced option for any extended backcountry trek, and will again go home with the Value Award.

Though not intended as a high volume or high output compressor, Viair’s 4055 ADA is, in my opinion, one of the most well-constructed units in the test. Everything from its sleeved wiring harness and flexible coil hose to its professional-grade brass couplers and machined aluminum casing suggests aerospace quality. It ran the coolest and quietest, drew minimal amperage, and didn’t skip a beat when subjected to high-pressure conditions. One of its more redeeming traits is its true, 100-percent, 100 psi duty cycle. Though a bit on the pricey side, this would be a worthy vehicle-mounted unit to pair with an air tank on a round-the-world expedition vehicle.

Editor’s Choice

And this brings us to the Editor’s Choice winner. Though ARB’s Twin portable may put a dent in your children’s college fund, spooling up a 5-second blender of margaritas will ease the pain. It performed at the top of every category, inflated tires a minute faster than any competitor, had excellent high-pressure output, and was the only unit to complete the pneumatic tool test. Though it did have the highest operating temperature, decibel readings, and amperage draw, the components are of premium quality and should be able to withstand the heat during long-term use. With ambient operating thresholds of below zero to 212°F, heat buildup shouldn’t pose an issue. The durable waterproof case is a big plus, and its 4-liter air tank renders the ARB Twin Portable a pick-up-and-go mobile shop.

2 Comments

Mike

August 5th, 2018 at 3:22 pmGreat read and informative article.

There’s one detail I wish you had covered though. While many of these compressors work great 90% of the time, high altitude will often substantially degrade the performance. I replaced the MV50 the first time I really needed it over 10k feet. I’ve been using the Viair 400P-A for a while now. I usually love it, but even that one struggles at higher elevation. Maybe tankless compressors aren’t ideal for high elevation use. That’s something I would have liked to seen tested.

Bob Temple

August 25th, 2018 at 3:45 amThanks for all that information in making me feel confident in selecting the Viair 400P-A for my Jeeps. A pleasure to see just how well it rates with others.