Traveling safely isn’t just about navigating challenging terrain—it’s also about ensuring your gear is secure throughout the journey. The NHTSA and CPSC report that unsecured loads alone are responsible for nearly as many US deaths on-road as all off-highway vehicle (OHV) recreation-related fatalities.¹𝄒² Remote wilderness travel usually involves some highway miles to get there. That combination of washboards, rutted roads, and high-speed highway travel makes securing loads especially important in the overland community.

Just as you wouldn’t neglect a first aid kit, your tie-down strap deserves careful consideration. Not only should you select the right one for the purpose, but you also need to use it correctly and ensure its purpose suits the vehicle. Scott Brady covered the latter topic well in the Spring 2018 issue (see sidebar below).

Using Your Tie-down Correctly

Traveling on uneven terrain and highways can cause loads to shift and straps to loosen. That’s why it’s crucial to ensure your gear is not only strapped down securely but also in a way that prevents vibration from loosening the straps.

Key Considerations

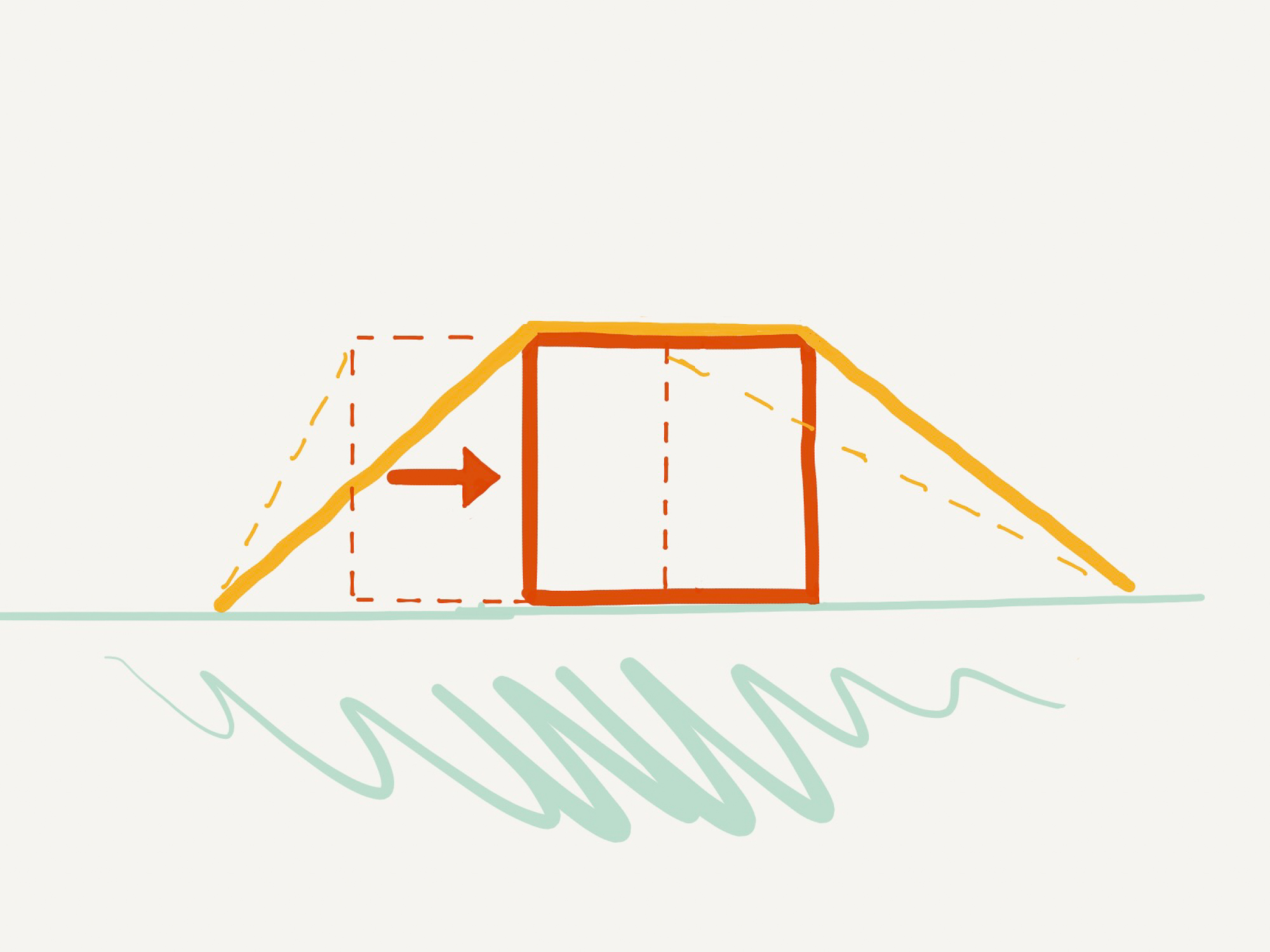

Center Your Load: Always ensure your load is centered between secure tie-downs close to its base. To illustrate this point, imagine strapping a 12-inch square box that is 8 inches tall to your vehicle’s roof. Movement induced by road vibration can result in an 85 percent loss of tension if it is strapped 5 inches off-center. Similarly, the geometry of a strap attached to a tie-down point 20 inches away from that box results in an additional 60 percent reduction in holding force. Even if you applied 100 pounds of tension to the strap, by the end of the trip, only 6 pounds is holding that load to the vehicle.

Secure the strap: Attach the strap with a girth hitch or gated carabiner instead of an open hook. When using a cam strap, manage the slack with a half-hitch to ensure the wind does not whip the cam loose.

Recheck: Recheck tie-down tension after a short drive to ensure no shifting happened during initial movement.

Choosing the Right Tie-down Strap

When it comes to selection, many good options are available. The contenders in this test include the tried-and-true NRS cam straps alongside newer, innovative solutions like the RhinoUSA retractable ratchet strap and Front Runner’s Stratchit. We also assessed the lightweight Rok Straps, known for their motorcycle-touring pedigree, alongside heavy-duty models like Bihlerflex’s ShockStrap, with a tested breaking strength of over 2,000 pounds. Each of these products serves a slightly different purpose, but all must meet the core requirements of durability, ease of use, and reliability over the long haul.

When evaluating for “ease of use,” we used the straps over the summer season, assessing for ease of tensioning, untensioning, and the likelihood of unexpected failures due to user error (e.g., an un-centered load). It’s worth noting that many of these straps include excellent tensioning systems that are more forgiving when loads shift after being improperly secured. To test the strap’s capability, we tensioned an off-center load and then centered the load by 5 inches (15 percent of the distance between the tie-down points, with the force meter installed inline at one anchor point), measuring the drop in the strap’s tension. This represents a common failure scenario: an off-center load is centered a few inches through vehicle vibration, resulting in a complete loss of tension. Indeed, tension losses in this test ranged from more than 80 percent to less than 5 percent.

When evaluating durability, we subjected straps to a direct-pull test, gradually increasing tensile load until a single point of failure. This test represents the worst-case situation (since the load’s force is typically distributed between multiple components, such as two strap hooks attached to two vehicle attachment points). Not all manufacturers define their breaking strength ratings this way. NRS, with its 1,500-pound breaking strength rating, assumes straps will be looped back and the load evenly shared between two parts of the strap. Others, like Rollercam with a 950-pound rating, assume a higher bar: the direct-pull test. In reality, both NRS and Rollercam straps performed similarly despite their different ratings. We also subjected the straps to accelerated corrosion weathering, exposing the straps to a highly saline (115,000 ppm) mildly acidic (pH5) spray 12 times over 96 hours in a humid environment at 125°F. Nearly every strap with metal hardware exhibited some corrosion, some substantially so.

Many straps lost significant tension when our test load was shifted 5 inches.

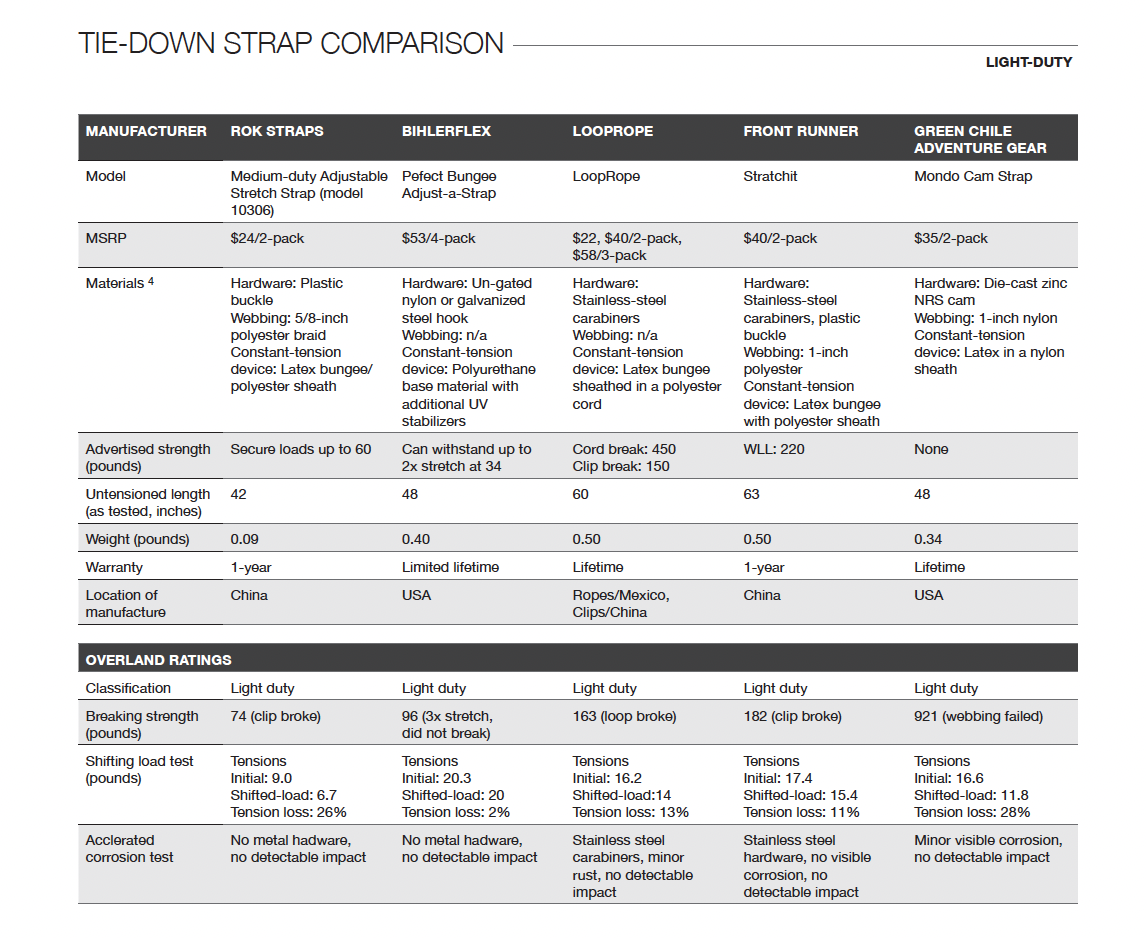

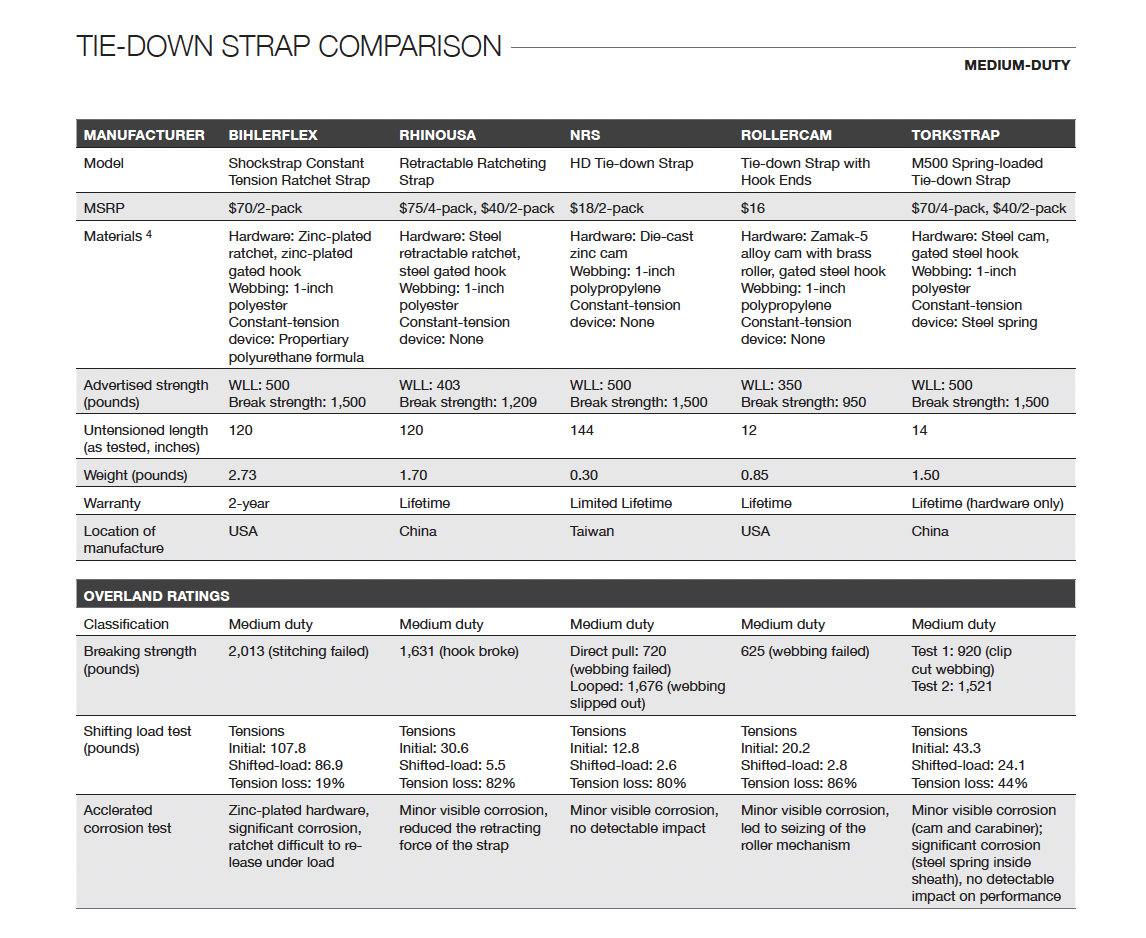

Ten straps were reviewed and divided into two different classes.

Light duty: Those used for securing small- and medium-sized bags, often in motorcycle touring or vehicle interiors. All of these straps have some UV protection; many have published load ratings and safer failure characteristics than bungees.

Medium duty: We selected straps with 1-inch webbing (except for Rok Straps, 5/8 inch), UV resistance, and a published breaking strength of 900 pounds or more. Appropriate for interior and exterior loads on 4WD platforms, such as strapping down a full jerry can or spare tire. While one manufacturer went so far as to advertise their straps for vehicle recovery, we strongly recommend against that for all medium-duty straps. Under-rated recovery gear can and has caused fatalities upon failure.

Heavy-duty straps were excluded as they’re oversized for typical 4WD-vehicle cargo capacities.

Breaking Strength

A force meter captures maximum tensile load in the breaking strength test.

Using a Hojila FM-500k force meter (with a rated ±0.2% accuracy), we subjected the straps to a slow pull, applying a gradually increasing tensile pulling force to the strap from our vehicle (which was in low range). The meter was calibrated to zero, and its accuracy was verified with a known weight. A second force meter was used when the tested performance deviated from the manufacturer’s advertised ratings. Both force meters were used in a parallel setup when the strap’s expected breaking strength was over 1,000 pounds. In the field, we don’t recommend attaching tie-down straps to a vehicle in this manner. Careful consideration was given to the rating and failure condi-tions of every piece of hardware in the setup to mitigate the danger of failure (e.g., using a cable dampener).

Light-duty Straps

Rok Straps Medium-duty Adjustable Stretch Strap (model 10306, 42 inches)

Gary McCay pioneered the adjustable elastic strap in 1998. Close to bankruptcy a year later, the death of a young boy from a traditional bungee cord spurred Gary to sell his house and double down on the invention.

Today, Rok Straps enjoys a well-deserved following in the adventure moto community, selling three classes of straps (light, medium, and heavy-duty) for securing loads from 40 to 100 pounds. We appreciated the built-in latex elastic (sleeved in a UV-resistant polyester) that maintains tension under shifting loads. We found ourselves reaching for this strap when securing interior loads or throwing a lightweight bag on the bike’s cargo rack. The strap’s attachment style is simple: two end loops allow you to quickly girth-hitch the strap around most objects, and the plastic hardware will leave your vehicle’s paint unscathed.

We tested the Rok-advertised medium-duty strap (we’re classifying light duty here). It had the lowest breaking point and the lightest weight (0.09 pounds) of the 10 straps tested. We applied 74 pounds of direct-pull tensile force before its plastic clip failed, adequate for its advertised purpose (they claim it’ll secure up to 60 pounds). The strap experienced a 26 percent loss in tension under our shifting-load test.

When buying this strap, it’s worth noting most retailers list an incorrect load rating. While Rok Straps doesn’t publish a WLL or breaking strength, they claim the 28-inch strap can secure 40 pounds, the 42-inch strap can secure 60 pounds, and the 60-inch strap can secure 100 pounds.

$24/2-pack | rokstraps.com

Bihlerflex Perfect Bungee Adjust-a-Strap Bungee w/Nylon Hooks (48 inches)

Bihlerflex assembles Perfect Bungee (and ShockStrap) in the USA. As the original manufacturer, in 2010, Bihlerflex co-developed a proprietary polyurethane formula with a high UV rating and has since added additional (undisclosed) UV-stabilizing chemicals.

The bungee is 48 inches but can be adjusted shorter. Bihlerflex advertises it will maintain its integrity at up to two times stretch (to 96 inches) with 34 pounds of force. Because of this stretch, the bungee lost only two percent of its tension under our shifting load test. In our tensile break test, we applied 96 pounds of force, stretching the strap to over three times its original length while unable to break it. While the strap gradually lost its internal strength through stress relaxation (think pulling chewing gum apart), no other strap we tested failed this gracefully. Twenty-four hours later, the strap had returned to its original length.

We recommend selecting a model with removable (ungated) hooks (nylon or galvanized steel). In our testing, it was common across brands that built-in nylon hooks would fail when overloaded. The failure occurred either at the hook itself or the attachment point. This model with removable (ungated) hooks did not fail at the hook-strap interface; if the hooks fail, you can easily upgrade them.

We saw no UV degradation, though Bihlerflex indicated that extended use in warm, high-humidity environments could lead to eventual material breakdown through hydrolysis (something we did not experience). Despite this, we consider this bungee state-of-the-art and aren’t surprised to see examples over a decade old still on the road.

$53/4-pack | theperfectbungee.com

LoopRope (60 inches)

The LoopRope we tested was a 5-foot latex elastic bungee with eight hitches and a polyester sheath. Two stainless-steel gated carabiners (rated at 150 pounds) make it easy to use for dozens of light-duty applications. Incredibly versatile, we used it as a gear hanger at camp and an emergency dog leash on the road. For those intimidated by knots (truckers hitch, anyone?), this can be a useful cord.

LoopRope performed well in the shifting-load test, experiencing a 13 percent loss in tension. However, in our tensile tests, the rope failed prematurely at an average of 163 pounds of direct-pull force (advertised strength of 450 pounds). While LoopRope suggests using its product to secure wheelbarrows, ladders, and other rooftop loads, it’s unsuitable for those purposes (consider a medium-duty strap below).

LoopRope markets itself as a safer alternative to bungee cords, and there is truth to that. Steel hooks on bungee cords are surprisingly dangerous; one study cites bungee cords as a common source of eye injuries, on par with power tools.³ Meanwhile, the minimal aluminum hardware built into the LoopRope is covered with a protective sleeve; there are no hook ends, and the separate carabiners are gated, making them less likely to dislodge when tensioning. Because the cord failed in our testing before the carabiners did, they are less likely to become projectiles.

The polyester sheath provides some UV protection, but the manufacturer does warn that “prolonged exposure to sunlight” may damage the rope. Based on Looprope’s test data, we would expect these straps to lose 18 percent of their strength after 200 hours of sunlight exposure. For that reason, these cords are best stored inside.

$22, $40/2-pack, $58/3-pack | looprope.com

Front Runner Stratchit (72 inches)

Frontrunner developed the Stratchit in 2013 with 1-inch polyester webbing, stainless steel carabiners, and a constant tension “bungee” integrated into a polyester sleeve. Fully stretched, the strap is approximately 6 feet in length. The bungee performed well in our shifting load test, experiencing a loss of tension of only 11 percent.

The high-quality stainless-steel hardware outperformed all other metal hardware in the 96-hour corrosion test, unaffected by the acidic saline environment. No other metal hardware emerged from that test in better condition, making the Stratchit a decent choice for coastal environments.

Front Runner advertises a 220-pound working load limit (WLL). However, the plastic buckle is a weak link that failed our direct-pull test at an average of 182 pounds of force. This performance makes it hard for us to recommend the strap for heavier loads, especially considering accidents can impart forces 2,000 percent higher than the mass of the payload. The polyester sleeve is a secondary point of failure if the elastic fails, although that was not an issue for us.

In day-to-day use, we wished the metal carabiners did not have keylock noses. Hooking the strap back onto itself is a very frustrating experience; the noses tend to dig into the Stratchit’s fabric-sleeve-fishhook style, making them hard to remove. As a result, the strap seems designed to attach to medium-gauge tie-down points, where the carabiner can clip onto the strap (like the Front Runner stainless-steel tie-down rings, SKU RRAC025). We reached for other straps with girth-hitch loops or larger carabiners when lashing to wider tie-down points (like the roof rack itself).

$40/2-pack | frontrunneroutfitters.com

Green Chile Adventure Gear Mondo Cam Strap (48 inches) Editor’s Choice, Value Award

Green Chile Adventure Gear created the Mondo strap after repeated failures in other straps’ plastic hardware, which caused them to lose gear bags on the trail repeatedly. The Mondo straps occupy a “Goldilocks” zone in the tie-down market: they have a constant tension built-in bungee, a simple-to-use cam, and are lightweight and strong. While they don’t publish a WLL, we found their breaking strength to be 921 pounds, higher than several medium-duty straps below despite weighing 0.34 pounds, less than most of our light-duty straps. The high-quality NRS metal cam buckles ensured we never had one fail, and they exhibited only cosmetic corrosion during our test.

The Mondo strap weighs about the same as the NRS strap, but the buckle is attached to a constant-tension latex bungee in a nylon sleeve. This mechanism allowed it to lose only 28 percent of its tension in our shifting-load test. Unlike the Stratchit, the Mondo strap can easily attach to tie-down points as thick as 1.5 inches in diameter by doubling them back onto themselves through their girth-hitch loops. The webbing is only 4 feet long, appropriate for moto and other light-duty loads (the intended use case). That said, you can special-order longer webbing or reuse an old ratchet strap’s longer 1-inch webbing.

I continuously reached for these straps for both interior and lighter exterior loads. Their fatal flaw is that you’ll use them so often that they will tend to disappear. Ultimately, after testing over a dozen straps (including those covered here), these are the ones I bought. I now keep two sets in each vehicle.

$35/2-pack | greenchileadv.com

Medium-duty Straps

Bihlerflex ShockStrap Constant Tension Ratchet Strap (120 inches)

Mike Knowlden, the inventor of the ShockStrap, pioneered the development of the constant tension cam strap in 1998. Working on an Alaskan crab boat, Mike became frustrated with traditional tie-down straps coming loose when securing crab pots in the Bering Sea.

This innovation has been the most significant advancement in exterior-vehicle tie-down safety since the development of the WWII-era ratchet strap. Mike sadly passed away in 2012, but the product lives on. Bihlerflex has been making the ShockStrap since 2015, having purchased the brand in 2021.

The ShockStrap was the highest capacity 1-inch strap tested, with durable polyester webbing and quality hardware. With an advertised 1,500-pound breaking strength, the ShockStrap outperformed that number by over 500 pounds, breaking at 2,013 pounds of force. The large ratchet allowed us to load the device’s UV-stable polyurethane spring with 108 pounds of tension. Even after a 19 percent drop in tension during the shifting load test, this strap applied more force than any other. For heavier loads, Bihlerflex makes 1.5- and 2-inch straps with a similar design and breaking strengths of up to 10,000 pounds.

This 1-inch strap is made with UV-resistant webbing, though the zinc finish showed significant corrosion in the salt-spray test. You’ll find yourself loving these straps but needing to replace the ratchet due to corrosion. Luckily, the elastic mechanism, which sets this unit apart, is built into the webbing portion of the strap and is compatible with any quality 1-inch ratchet. I selected this strap for the rare occasion when we had to lash something heavy to the roof.

$70/2-pack | theperfectbungee.com

RhinoUSA Retractable Ratcheting Strap (120 inches)

RhinoUSA started as a family business in Murrieta, California, with the aim of building better powersports accessories. The company sells a wide variety of straps (all of which are manufactured abroad), most of which are overkill for the overland community (see sidebar on payload). This includes a heavy-duty 1.6-inch ratchet strap that contains an innovative self-tensioning device with an advertised break strength of 4,000 pounds. We did not test that strap but would consider it when carrying a heavier, trailered load.

We evaluated a medium-duty retractable 10-foot strap with 1-inch webbing. The polyester webbing retracted similarly to a seatbelt without compromising strength. The strap exceeded its advertised strength of 1,209 pounds; ultimately, the hook broke at 1,633 pounds of force. The strap exhibited some corrosion in the salt-spray test, which reduced the self-tension force of the retracting mechanisms (at times, inhibiting retraction). As a result, we wouldn’t recommend these straps for exterior vehicle use on extended overland trips.

The retracting mechanism could be helpful for someone intimidated by a traditional ratcheting tie-down, as the user does not need to thread the strap through the ratchet. For those comfortable with ratchet operation, we’d recommend choosing a constant-load tension technology (like the ShockStrap). Without a constant-tension device, this strap lost 82 percent of its tension in the shifting-load test.

$75/4-pack, $40/2-pack | rhinousainc.com

NRS HD Tie-down Strap (12 inches)

Bill Parks, the founder of NRS, introduced the NRS strap in 1974 after several river rafting fatalities, which he felt could have been prevented with an easier-to-release tie-down; Parks eventually landed on a spring-loaded cam.

Today, the blue NRS strap is a tried-and-true classic. The UV-protected polypropylene webbing is hydrophobic, comes in various lengths from 1 to 20 feet, and includes a version with open-clip and girth-hitch ends (which we prefer).

NRS advertises this strap with a working load limit (WLL) of 500 pounds and a break strength of 1,500 pounds. In our direct-pull test, however, the strap webbing broke at 720 pounds. NRS informed us that since most of their straps are designed to loop back onto themselves, similar to a belt, the advertised 1,500-pound break strength assumes the load is distributed evenly across two sections of the strap. When tested in this configuration (webbing fed through the attachment point and double-backed to the cam, reducing net load), the strap held up to 1,676 pounds before failing.

The strap has no constant tension mechanism; as a result, it lost 80 percent of its tension during our shifting load test, putting it at a disadvantage for overlanding use cases where loads commonly shift due to vibration.

$18/2-pack | nrs.com

Rollercam Tie-down Strap with Hook Ends (12 inches)

Rollercam, first developed in 2003, is a relatively new entrant. The materials used in the cam appear high grade: the cam itself is molded using a corrosion-resistant Zamak 5 alloy with stainless-steel and marine-grade brass components. The polypropylene webbing is UV-resistant and hydrophobic, similar to NRS. However, Rollercam introduced a twist: a roller is built into the cam, allowing smoother tightening. The value of this thoughtfully designed cam was especially appreciated after using the Torkstrap (see below). In our test, the roller allowed us to apply more tension to the strap (20.2 pounds, 57 percent more than the NRS strap). However, because it has no constant tension device, it lost 86 percent of that tension in our shifting-load test.

Like NRS, Rollercam sells various widths, lengths (from 1 to 20 feet), attachment points, and two different colors. Rollercam also has an innovative Roperoller cam and models useful in the overland community, such as a cam strap with L-track ends. Models with carabiner or gated hook ends allowed for easy loading and unloading. All attachment points and hardware are triple-tacked to the webbing, creating a secure bond.

The cam withstood the salt spray well with minimal corrosion; however, the roller eventually seized. In our pull tests, the polypropylene webbing failed at an average of 625 pounds of direct-pull force, similar to NRS. This is below the company’s in-house tested performance of 900+ pounds. While the company is investigating our findings further, both numbers are beyond their advertised WLL of 350 pounds.

$16 | rollercam.com

Torkstrap M500 Spring-loaded Tie-down Strap (14 inches)

Torkstrap, like Mondo straps, combines a cam mechanism with an elastic constant tensioner device (in their case, a steel spring). The cam and hook hardware performed well in the corrosion test, and while the steel spring rusted, it didn’t affect functionality. Unlike latex, we expect the steel spring to have a longer service life since it won’t degrade under UV exposure. In the first tensile-strength test, the strap broke at 926 pounds, well below the advertised 1,500-pound breaking strength. The square nature of the cam design tended to cut into the strap at high loads, causing the strap to rip at the connection point. The second test (a newer model with a slightly different design) performed better, maintaining integrity until 1,521 pounds. In the shifting load test, the strap suffered from the short travel length of the spring, losing 44 percent of its tension.

This cam was the most difficult to thread of the units tested, and a bit of patience was needed to push the rope through the high-friction interface. The Torkstrap’s gated hook ends were a saving grace in this regard, as they allowed us to loosen and unhook the strap in one piece (instead of pulling it out of the cam). The sewn loop ends allowed for flexibility in choosing tie-down points. While Torkstrap advertises using their straps for vehicle towing, we cannot endorse that use; hardware on or connected to underrated straps can quickly turn into deadly projectiles.

$70/4-pack, $40/2-pack | torkstrap.com

—————

- NHTSA: 2023 Secure Vehicle Load Fact Sheet (16,878 injuries and 732 fatalities annually).

- CSPC: 2023 Report of Deaths and Injuries Involving Off-Highway Vehicles with More than Two Wheels (cspc.gov)

- Potockova, A & Strmen, P & Krásnik, Vladimir & Olah, Z. (2010). Mechanical injuries of the eye. Bratislavské lekárske listy. 111. 329-35.

- A note on webbing: Webbings included polypropylene, nylon, and polyester. Polypropylene is the least expensive webbing material type. It’s hydrophobic (resisting mildew) but not as strong, abrasion-resistant, or UV-resistant as nylon or polyester. As a result, most manufacturers add UV inhibitors to polypropylene. Nylon is less UV-resistant than polyester, but it is high-strength and abrasion-resistant.

Sidebar: A Note on Payload

It’s important to know both your vehicle and roof rack’s payload capacity, being sure to adjust them for any aftermarket modifications. You can calculate your vehicle’s payload by subtracting the curb weight (net of any modifications) from the gross vehicle weight rating (GVWR).

Weight and placement matter more than size: vehicles often “fit” more gear than they can “hold.” Stock payloads as low as 1,200 pounds on high-articulation 4WDs are common. An aftermarket roof rack, bumpers, winch, and sliders might decrease your payload by 400 pounds, leaving enough remaining payload for four 200-pound adults (and no bags).

Regarding placement, keep payloads off the roof (with high center of gravity and low carrying capacities). Instead, place heavy gear low and between the axles (lashed in the second-row footwell is ideal).

Finally, towing may reduce nearly all available payload due to the vehicle’s gross combined weight rating (GCWR). For example, a high-articulation SUV might have a GCWR of 8,117 pounds, a curb weight of 4,449 pounds, and a towing capacity of 3,500 pounds. For that vehicle, towing a 3,500-pound trailer would only leave 168 pounds for aftermarket accessories, the driver, passengers, and gear. It may be that you don’t need any tie-down straps at all.

Editor’s Note: This article was originally published in Overland Journal’s Gear 2025 Issue.

Our No Compromise Clause: We do not accept advertorial content or allow advertising to influence our coverage, and our contributors are guaranteed editorial independence. Overland International may earn a small commission from affiliate links included in this article. We appreciate your support.