For most overlanders, the idea of building a rig to fit our own personal needs can be not only fun, but educational as well. Depending on our skill level, we’ll take on tire and suspension swaps, mount a bumper and winch, or install a dual-battery system. The more technically inclined might even delve into setting up ring and pinion gears or installing a locker. Kick that up a notch and we’ll call it an ARB air locker. If you are like us, you may have wondered what goes on inside that mystical metal contraption when you push “the button”? We recently presented this question to people when met on the trail whom were sporting ARB stickers. The general response was, “I don’t know. It’s a button on the dash. I push it, it goes click, and away we go.” We decided to super-size the question, and the answer, with a visit to the ARB facility in Melbourne to get the inside scoop on what causes the click, and away we go.

So what did we discover about the air locker? The first thing was that the ARB crew takes pride in stamping made in Australia on each locker. Though some components are source from specialty foundries that offer premium European materials, Air Lockers are engineered, machined, assembled, and tested in Australia. Nothing in the box (short of maybe the zip ties) comes from the land of the Ming Dynasty. Keeping production close to home allows ARB precise control of quality and engineering specifications, and ensures that every unit fits right and functions properly every time. Another point of discovered was the level of extensive research and testing that goes into every application before it sees the trail.

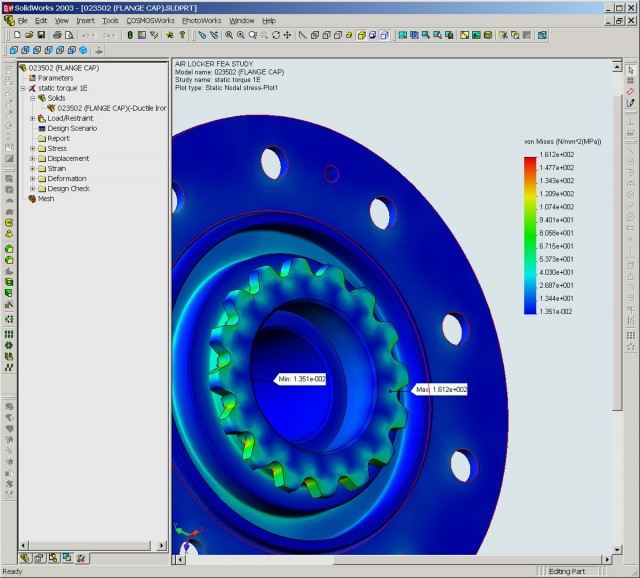

ARB engineering supervisor Daniel Bongerd took us through the early design stages of creating an air locker. The use of CAD and Solidworks allow engineers to create, analyze, and test a new product in the digital laboratory.

Because the virtual lab can push the design-load envelope much further those encountered in real life situations, FEA is used to identify possible failure zones. Given the known material properties, each surface is color coded based on amount of potential stress to that area. In this image, the blue areas represent the least load while the red areas represent the heaviest load (up to 161.2 megapascals or 23,400 psi). This is roughly 30 percent of the 73,000-psi maximum design load for this particular material. After passing the FEA stage, specifications are sent out for prototype units to be built.

Automotive castings are usually only batch tested (a sample of each batch is tested and assumed to represent the entire lot). ARB requires their supplier to test each casting to insure it falls with in specified hardness range. ARB considers this insurance against the possibility of a flawed product making it into circulation.

Engineering Protocol

We talked with engineering supervisor Daniel Bongard to find out what happens behind the scene. It starts in the conceptual and design stages, where ARB CAD (computer added drafting) jockeys build models on a digital drafting table. Once the design is complete, virtual lab engineers test durability with a process called Finite Element Analysis (FEA). FEA renders a color-coded image of stress points and possible failure zones. If it survives the FEA processes, specifications are sent out for prototype units to be built.

Due to the fact that stuff happens in the real world, ARB performs an extensive series of physical tests with the components the unit will be installed into. For example, an 8-inch Toyota locker would be paired with a Toyota differential and axles, and taken to ARB’s destructive testing lab. The assembly is placed in a fix jig and torsional load is applied to the axle shaft until something snaps. That “something” can be any component other than the locker. (Writer’s comment: don’t try this at home—riot shields and Kevlar vests are highly recommended).

If the pre-pubescent locker hasn’t been beat up enough, it is then taken to the temperature lab where it is heated and cooled to 120°F and -24°F respectively, and subjected to an acute wheel-spin engagement test to simulate a full-load wheel-hop condition on a 100-percent traction surface. If the unit survives the aforementioned gauntlet, it is then run through a longevity test of 20,000 actuation cycles of the pneumatic mechanisms. By this point one would think the unit is ready for the consumer—but not just yet. The ARB guys then get a chance to play with it for a while in Australia’s Outback in some of the world’s toughest conditions.

We asked Bongard why ARB performs such extensive testing. The response, “Everybody claims to have the best materials and processes, but if you don’t pit them against each other in an objective environment of laboratory-controlled abuse then you never actually know. Usually, these materials and technologies fall more under the banner of aerospace than automotive, as this sort of strength is not needed in a regular car.” ARB credits the air locker’s success to simplicity and their unwavering commitment to strength and quality.

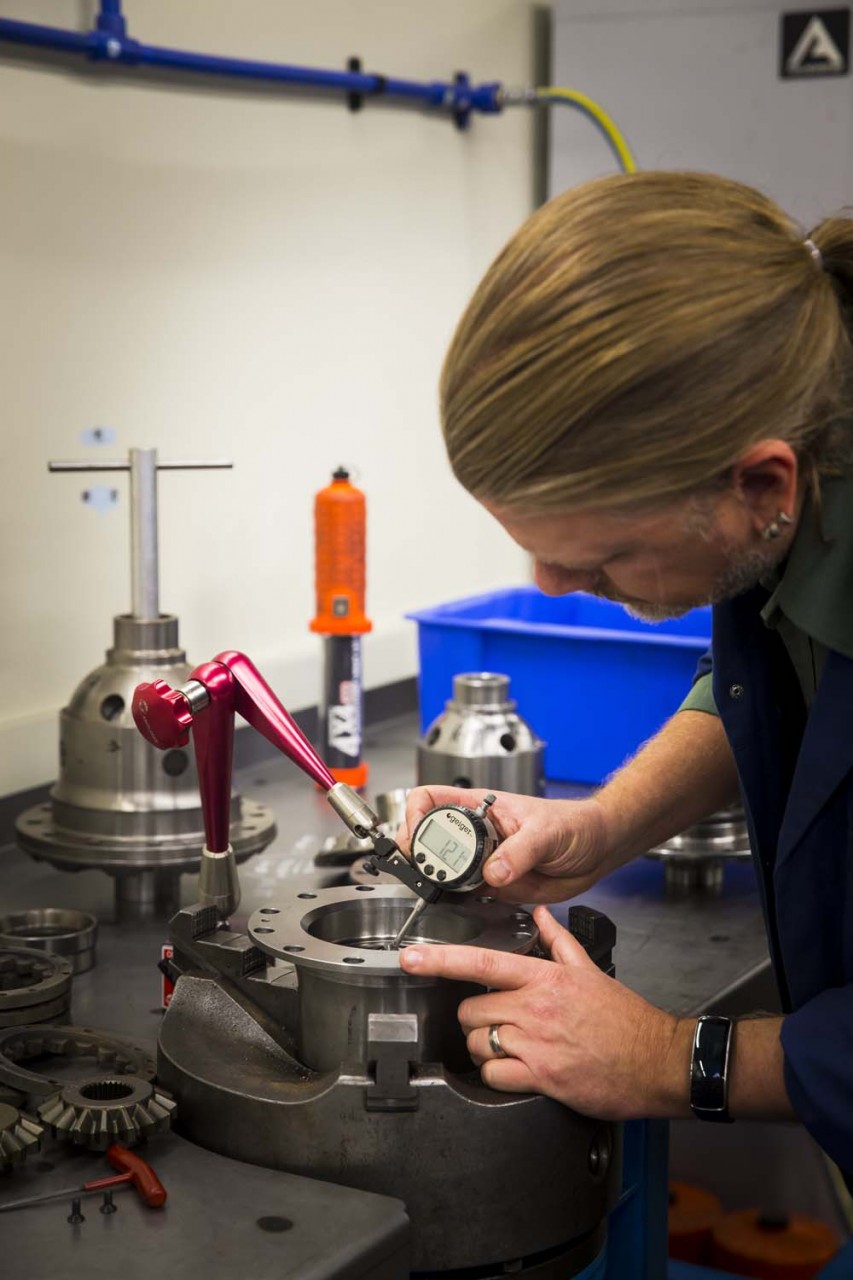

Raw flange caps are initially milled for the carrier-bearing surface, and then set in line for carrier bolt holes to be drilled. Mazak five-axis mills ensure aerospace quality tolerances. The bearing surface, for example is mill at minus .00mm, to plus .003mm. At this point, the semi-finished cases are placed for final millwork. ARB has more CNC mills that we could shake a stick at, each of which is dedicated to a specific application. After side gears and seal housing assemblies are cut and deburred, they are chemically steam cleaned, inspected, and placed for assembly.

Because the locker is operated pneumatically, it is crucial that it functions within the designed pressure limits. Each unit is manually charged and checked for engagement and disengagement of the spring-loaded clutch gear.

In the destructive testing lab, each application is pitted against the components to which it will be installed in. With the differential an axle fully assembled, the axle shaft is put under a load until something snaps. That something can be anything other than the locker. Prior to a full production run, the unit is subjected to an acute wheel-spin engagement test. The axle is spun at a speed of 40 mph with a high-torque, three-phase motor, simulating a condition of 100-percent wheelspin (one wheel spinning in the air and one on the ground). A computerized controller then repeatedly engages and disengages the unit. Though ARB highly advises against this type of abusive driving on the trail, they want to know that their lockers can take it. The unit is then run through the engage/disengage cycle 20,000 times to ensure longevity of components.

What’s New

In the last decade ARB has redesigned all of their lockers to implement timed gear technology. Though the original design wasn’t flawed, the use of timed gearing, or roll-through geometrical design, has reduced the number of internal moving parts, increased strength by 40 percent, and assures maximum “locking” strength at every rotational lock-up position. To answer the question of what happens behind your differential cover when you click the button, see the sidebar below.

As of recent, ARB has moved to “cold net” forged gears rather than billet cut gears. Though in the past I have considered billet to be optimal with regard to strength, molecular-level metallurgy is my strong suite. Bongard said, “Cold net forging yields a topographically ideal carbon grain structure that improves shock absorption, wear and fatigue resistance, and provides a static loading limit above all other known methods. Billet cut gears can only offer a homogeneous axial grain structure, which wins against cheaper cast gears, but billet cut gears can’t come close to the advantages of taking complete control over the direction of grain structure from tooth to tooth.” With a 40-year track record of placing quality as job one, I’m going to take ARB’s word on this one.

With the increasing market for high-level racing differentials, they launch the CE project. In short, CE is the development of racing differentials, such as the 9-inch Ford, that will withstand the brutal environment of Ultra4 buggies. CE units utilize a bulletproof (and very expensive) case and redesigned bearing surfaces that energize, or drive gears into their seats. Bongard said, “The force exerted on an Ultra4 differential is similar to someone trying to pull the gears out of the case with a 3-foot-long, 700-horsepower pry bar.” Another development that has come from the CE research is the use of locking tabs on ring gear bolts (competition 9-inch Ford diffs only). Under severe use, the bolts holding the ring gear to the case can work themselves loose. The new locking tab eliminates this risk.

So what is next for the eight wonder of the world? Although the air locker was originally designed for just a handful of applications, ARB now has its flagship product, which is available in more than 80 countries around the world, available for more than 100 vehicle models. While most of us simply know the ARB dash toggle makes you go, we thought you might want to know just what happens when you slide your backside into the seat, get into a jam, and hit “the button.” arbusa.com or arb.com.au 01-425-264-1391

How it all Works

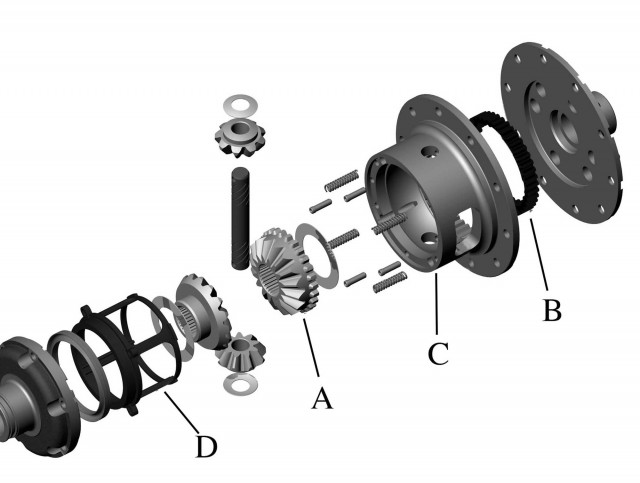

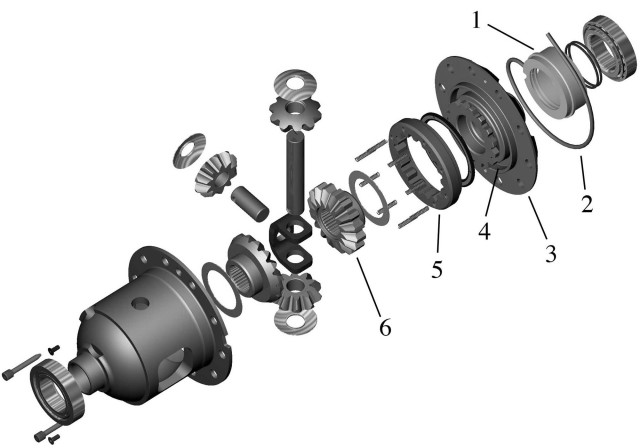

If you are a complete gear head, read on. If not, continue on as well; this stuff is fascinating. Below are several cut-a-way graphics of the original Air Locker design (the movable squirrel-cage method) and ARB’s timed gear technology.

The original design shown here implemented a 21-position system of engaging—locking the side and spider gears. The side gear (A) had a different number of engaging points than gear teeth. Therefore, when clutch gear (B) meshed with the differential case (C) and the side gear, the side gear would lock on whatever tooth was handy. This configuration would unevenly distribute the load between the teeth of the side gears and spider gears. Though ARB has always used aerospace-quality materials, they realized that timing the engagement of the side gear, clutch gear, and case, would increase the unit’s strength. They also modified the locking mechanism itself, eliminating the piston (D), to reduce the number of moving parts.

What is a timed gearing technology? This is where it gets fun, so follow along. The timed unit implements a splined side gear. This means that the teeth on side gear (A), and the number of side gear engagement positions (B) are matched. The splines also match, or are timed with, the engagement teeth in the clutch gear (C) and the flange cap (D). When engaged, the contact surface of the spider gear (E) and side gears is maximized. They are in perfect alignment and pressure is distributed equally throughout the contact area.

Where does the air come from? An onboard compressor supplies 85 psi to the seal housing assembly (1) via a copper line (2). Air is then transferred internally into the flange cap (3) which pressurizes the galley (4), a sealed circular groove in the flange cap that the clutch gear (5) rides in. Under pressure, the clutch gear slides forward (to the left in this graphic) and engages the side gear (6). This couples the side gear, clutch gear, and flange cap, locking the differential and virtually spooling the axles.

Want to watch a great video on exactly what goes into manufacturing an ARB Air Locker, check out this Youtube video.

King of the Hammers, Ultra4 champion, and Off-Road Motorsports Hall of Fame member Shannon Campbell has been running ARB Air Lockers since his first competition back in the 90s.