Editor’s Note: This article was originally published in Overland Journal’s Gear 2023 Issue.

The year 2009 was a memorable year for many reasons: US Airways Flight 1549 hit a large flock of geese shortly after takeoff and successfully landed in the Hudson River, the swine flu ravaged the world, and Overland Journal printed their 12-volt winch review in the Gear Guide. A lot has changed in winch technology in 13 years, but some things have stayed the same.

Some people argue that a winch is an antiquated tool. Vehicles today are more capable than ever, with traction control systems, improved tire technology, and the addition of traction aids such as traction boards. It is true that 90 percent of the winch recoveries I have ever done are to pull someone else out of a predicament they found themselves in. But that means that the other 10 percent was spent pulling myself out. I’d argue that anyone traveling in a solo vehicle should see a winch as mandatory. And yes, a winch can even be used in the desert without a tree in sight.

Over the course of a month, we tested five 12-volt winches. We broke three winch ropes and had to call off testing a few times due to some interesting finds (more to come on this). The intention of the testing was never to break anything or to see if we could push equipment past its published ratings. Instead, the goal was to explore data and impressions along with real-world functionality to empower the potential buyer.

Winches require special training, and there is always more to know and learn. What you read and see in this article is not always proper or correct usage. The point was to test the winches in a way that pushed them to their edges of capability, to know what performs best when it needs to work. When you find yourself alone in the desert, and your winch is your only tool to get out, product failure is unacceptable.

Testing and Considerations

If you’re thinking of buying a winch, my advice is to research and buy the best you can afford. This item has a lot asked of it and is best described as a safety device, much like a first aid kit. The winch lives on the front of a vehicle, getting covered in mud, snow, salt, and rain; it lives inches from the radiator, getting heat-soaked and cold-cycled daily. We often don’t unspool it for years and then ask it to perform flawlessly when the going gets tough. It likely is one of the most mistreated items you’ll ever put on your vehicle.

As important as the winch is the mounting system, as illustrated during our testing. The factory winch mount on the Jeep wasn’t up for the task of pulling to stall and was a contributing factor in some of the winch ropes breaking. I’m a fan of using winch mount systems from winch manufacturers because you know the system has been tested together. Other mounting systems, such as ARB, go through failure mode effects analysis or FMEA durability testing, which is costly but gives a buyer confidence. Many companies have never performed any real analysis of their product other than some personal testing or product placements to see if they failed or not. Unfortunately, when it comes to load factors and safe use, a pass/fail grade is inadequate and something you shouldn’t be subjected to as a buyer.

Adding a winch to your vehicle does add some complexity. You’ll need a lot more than just the winch itself, and the additional items needed will likely require more investment than the winch. You’ll need a good mount, suspension that can compensate for the additional weight of the mount and winch, and possibly a charging system upgrade or dual battery system to handle the electrical load, or at the very least, a basic winch kit. You might consider upgrading the winch rope, hook and fairlead as well. Look at the winch as a system, and design yours for what you need—it’s not the time to cut corners.

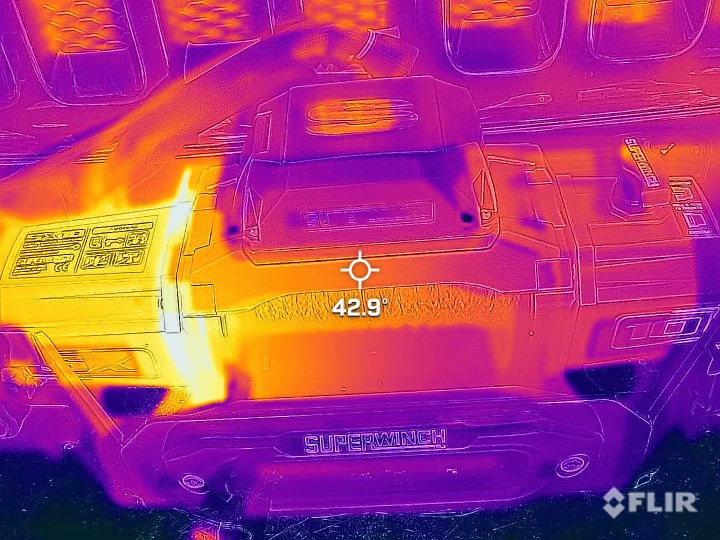

Looking at the Superwinch with a thermal camera, you can clearly see the motor heat, but the highest heat is from the winch’s braking system. This picture was taken while lowering the vehicle using the winch. Also note the heat from the winch rope itself; this is residual heat transferred from the drum.

The most important accompaniment to the winch is proper training in its use. Think of winch training as two separate parts: First, obtain fundamental training on operation and the dos and don’ts of handling the winch and its parts; it will require a few hours of hands-on instruction. Your instructor will explain the pinch points (literally, in this case) and how to correctly spool, field wrap, and care for the winch and its accessories. Second, you’ll want to learn how to safely use the winch to extract yourself or someone else. The sky is the limit on how advanced you can get with a winch pull. Start by performing a single and double line pull with an instructor’s supervision to understand the physics at play during the recovery. You’ll become versed in minimum breaking strengths (MBS) and working load limits (WLL) and why you need to know what you’re working with.

Choices and Selections

The electric winch industry has grown by leaps and bounds in the last 20 years. In the 1960s and 1970s, it wasn’t uncommon to see power take-off (PTO), engine-driven winches with complex power transfer systems, hydraulic winches that used additional pumps or your power steering pump to operate, or even engine-driven capstan winches that used large ropes and two people to get unstuck. All of these options have certain advantages, but the electric winch makes the most sense for overland use. The ease of fitment to multiple vehicles and the reliability of the electric winch have made it king in the world of recovery.

One of the reasons electric winches work so well is that our modern electrical systems are designed for high output. It wasn’t uncommon in the 1960s for many carbureted vehicles to have generators or alternators that only used 40 amps or less. Your vehicle’s batteries are much more reliable and capable of handling extreme amperage loads and can still recover and charge. Nowadays, it’s not uncommon now for a charging system to exceed 150 amps and incorporate large batteries. Many install dual-battery systems, which ease the load on a single battery and can give you a backup option depending on how they are wired. If you use your winch often, you’ll need to ensure your battery is still in good shape. Have a local shop run a conductance test before heading out to give you a better idea of the internal condition of the battery’s cells.

The small form factor of most electric winches is a major advantage, as it will work for most vehicle fitments. Currently, it is common for winch mounts to make access to touching the winch or the drum nearly impossible. While I don’t advocate for winch mounts that wouldn’t allow a user to make corrections to the spool or even see the spool, I understand that it sometimes is the only way to make it fit. If I had a choice, though, I’d choose a mount where I could see and make corrections if need be. The ability to respool correctly and to prevent rope pinching is critical. I’ve seen winches get a rope pinch that was nearly impossible to fix and would have been even more difficult if I couldn’t see the spool.

Another nice feature of the electric winch is the simplicity of the electrical hookup. A winch designed with an integrated control box often only requires routing the winch cable leads through a safe passage to the battery and connecting the positive and negative leads to the battery. Many winches also incorporate or offer a remote control box to be mounted separately from the winch itself. These installations allow more customizable mounting and access to the controls. One thing often overlooked is the ability to disconnect the winch from the electrical system in an emergency (see sidebar).

Left: Pulling the MaxTrax winch rope while utilizing a fuse shackle. Right: The red winch protective sheath was no match for the heat generated from the torture test.

For this test, we selected five electric winches in the 9,500- to 10,000-pound pulling range to be more applicable to the most overland vehicles in use. As full-size trucks become more common, we may need to re-evaluate with a higher pulling weight test. A good rule of thumb is to have a winch rated to 1.5 times your gross vehicle weight as loaded for travel. So weighing your vehicle to determine an appropriate winch size is critical; don’t forget to add the weight of the bumper and winch when deciding.

The winches were fitted with synthetic rope and tested as delivered by the manufacturer. We used the fairlead provided with the winch and weighted the winches as they would be installed. Winch hooks were tested initially, but after some ropes broke, we eliminated the hook from the test to decrease the system’s weight and increase the safety level (hook notes and observations were taken). Installation instructions were followed, and torque settings on the hardware were observed.

Jeep provided a new Rubicon 392 and installed the factory Mopar winch plate (Mopar part# 82215182AC). The grill was removed for easier access to the winch and ease of installation. The outer shell (non-structural) of the factory modular bumper was also removed for access and to observe the winch during testing. We found two significant issues with this mount. While stall-testing the first two winches, we broke two winch ropes. Upon further inspection, we identified that the winch mount was flexing from 3/4 of an inch to over an inch under load. We observed that near stall, the body of the winch sometimes would make contact with the mount. We also found that the slot in the front of the mount for the rope to pass through and the fairlead to mount were small enough that the rope could touch the metal and expose it to abrasion and potentially a right angle or sharp edge while loaded. After experiencing these failures, we changed the mount to a Warn JL winch mounting tray, which alleviated the problems.

The winches were tested to verify their manufacturer’s rated pulling power by strapping the rear of the Jeep to a tree using rated, static recovery equipment. The winch was then unspooled to the manufacturer’s recommended number of minimum wraps remaining (2/3 drum, 10 wraps with synthetic line) and connected to a Dillion Edxtreme 25,000-pound strain gauge to measure the loaded pulling capacity. This gauge is used in the overhead lifting industry and is accurate to .1 percent with the capability to record the peak load. The purpose of the test is to see if the winch stall capability meets its rated capacity and to find out what the stall load capacity is. I consider this a pass/fail test and should be interpreted as nothing more than whether the winch is capable of the advertised weight. It should be noted that charging voltage, battery storage capacity, and voltage drop are contributing factors to the winch’s capacity to stall, and peak performance is dependent on the vehicle being in perfect working condition. As such, anything within 3 percent would be considered within that margin of error.

The second test should be described as a torture test and consisted of three consecutive 70-foot pulls from a 3-degree slope that increased to a 23-degree slope. The motor, gearbox, and drum temps were noted prior to pull, and the test was done without stopping while winching in. Once the vehicle reached the top of the incline, temperature measurements were retaken at the motor, gearbox, and drum. Amperage was recorded for the entire test, and max amperage was recorded. The vehicle was then lowered down the same incline, stopping three times to test the brake holding. Once the vehicle was lowered back to its starting location, the test was repeated for three cycles. This test is taxing on the winch and the charging system and pushes their limits. The flattest portion of the test at the bottom allows the winch to pull on its first layer and provide maximum pulling power, but by the time the winch has reached the last 10 feet, the winch is pulling on its fourth layer and is near stall to keep moving. This test would replicate multiple pulls in the worst way possible.

Warn, ComeUp, Superwinch, Ironman, Smittybilt, Ramsey Winch, and Red Winches were all invited to be represented in this review. Smittybuilt never replied, Ramsey committed to providing a Patriot 9.5 but never came through, and Red Winch declined to be involved due to their lack of network in the United States.

Warn M8274

The Warn 8274 has a long history of dependability and reliability, participating in the Camel Trophy and numerous winching challenges worldwide. Introduced in 1974, it replaced the Belleview model that had been around since 1959 but is similar to the original model. The M8274 took the Editor’s Choice Award in Overland Journal’s last face-off.

Design improvements since 2009 have increased capability and reliability. Warn changed the heat treating and coating on the spur gears, converted to a contactor solid state control system, and modified the motor to increase the rated pull power from 8,000 to 10,000 pounds. Minor but meaningful adjustments to waterproofness were made to lengthen the product’s lifespan. Everything about this winch is premium, from fit and finish to the well-coated surfaces. The included attachment hardware is solid and properly sized.

The M8274 is the only foot-forward (front attachment to the mount versus the bottom) winch of the test and is well-suited to pulling; it’s an uncommon configuration requiring a specially made bumper. We modified a Warn universal 8274 mounting plate with fabrication and brackets to work with the Jeep, an acceptable solution for testing purposes.

This model is the only non-planetary gear-type winch in the test, using spur gears in an oil bath with an external motor and an external disc braking system. Spur gears are strong and fast by design, and the M8274 operates at over 37 feet per minute unloaded. Having this much speed can be beneficial, but for most of us, it’s too fast: slow and steady wins the race in vehicle recovery.

On the stall test, I stopped at a pulling capacity of 7,985 pounds to avoid a potential break when the mount started twisting. The winch was not struggling before terminating the test, and I am confident it would have met and likely exceeded the 10,000-pound rating.

The free spool worked well. The T-handle shape protruding from the side takes some effort to pull out, but once disengaged, the spool spins freely. The Spydura rope is a time-tested Warn product and functions as expected. The provided hook is not as high quality, and an upgraded Epic winch hook, or, even better, a Factor 55 thimble (Warn now owns Factor 55), would be a better match.

The controller is classic Warn style, with a robust cable and keyed connector, and the control box is integrated onto the winch body but can be remotely mounted with a Warn kit. Recent enhancements include an Albright contactor system, improved waterproofness on the control box, and refined rubber covers with enhanced grip and durability for the handheld control. An easy-to-read, in/out switch is manageable with gloves, and the simple diagram portraying switch function inhibits incorrect and dangerous usage.

The braking system is an often overlooked feature but an important one. It holds the vehicle’s weight when the winch is stopped and allows you to lower the vehicle with the winch. The M8274 external disc brake is a very clever design, always moving while the motor is in operation, allowing for additional cooling.

Pros

- Amazing braking and predictability

- Historically proven

- Great support and repairability

Cons

- Hard to fit to current vehicles

- Extremely heavy

- Cost

$3,559 | warn.com

ComeUp Seal Gen2 9.5rsi

ComeUp has been exclusively making premium winches since 1975 and introduced its products to the US market in 2013. The family-owned-and-operated Taiwan-based company produces 75 percent of its components, including motors, allowing for quality control. For many years, ComeUp manufactured winches for Superwinch, but no longer.

The Seal Gen2 line is the second generation of winches to promise a waterproof product that works while submersed without issue. We did not test this claim, but a friend of mine has used it often in difficult situations for a few years now and attests it’s the most reliable winch he’s ever owned. While he’s had to rebuild other-brand winches every few years due to water and corrosion, it’s been unnecessary with his ComeUp. Publisher Scott Brady used ComeUp winches on the Expeditions 7 trip and said they never failed to deliver, even in extreme temperatures. He appreciates that the business solicits feedback to improve upon design and reliability.

The 9.5rsi provided to us has an integrated contactor control system. The installation manual’s instructions were clear, and the hookup was straightforward, with a traditional bottom foot mounting system and good-quality hardware. The hook was robust but would not close around a standard bow shackle pin. The synthetic rope was well-marked with red paint for minimum useful length indication. We broke the rope on the winch approximately 10 inches from the fairlead. I requested a second rope from ComeUp, suspecting the flexing bumper caused the failure. After installing the replacement and retesting the winch to stall, a few strands broke nowhere near the fairlead, indicating rope quality could be improved. Final testing was completed using MaxTrax ultra-high-molecular-weight polyethylene (UHMWPE) winch line.

The exterior of the winch has a simple on/off switch that needs to be activated for operation, eliminating inadvertent actions and promoting safety. Once the button is pressed, external lighting displays the battery voltage, winch temperature, and flashing fault codes when applicable. The hand control is high quality with apparent detents, easily manipulated while wearing gloves, and the heavy-duty cord and connector should last a long time. The small remote wireless handset paired easily and worked perfectly during testing with no discernable delay during use, though storing it in a pocket could lead to accidental activation.

During testing, the 9.5rsi exceeded the maximum stall test with a 9,755-pound pulling capacity. The clutch handle never jammed in position and slid easily into free spool and an engaged setting, although it was extremely difficult to pull rope from—a smaller-statured person would struggle, and it did not loosen up. The additional pull effort required is distracting and could lead to poor decision-making.

Line speeds were more than adequate. When loaded, winch noise obviously increased, and while it didn’t appear to struggle, the sound level indicated otherwise. ComeUp uses a patented cone braking system to keep the braking heat away from the drum, but the winch sounded like it was filled with gravel while lower when hot, perhaps the result of heat soaking the gearbox from the brake system during lowering. The vehicle continued to roll backward 2-3 feet before stopping while lower, and a loud ratcheting noise ensued when trying to stop the vehicle while lowering, shaking my confidence.

Pros

- Sealed from water and weather

- Good customer support

- Braking system keeps heat away from the drum

Cons

- Provided rope didn’t perform well

- Wireless remote too small

- Vehicle continued to roll back while stopping during lowering

$1,580 | comeupusa.com

Ironman Monster 9500

Ironman products are renowned in Australia, where the company was founded, and their catalog of overland equipment from suspension to soft goods is extensive. They specialize in offering budget-conscious products that also perform well, and the Monster 9500 is a perfect example.

The design of the Monster 9500 hearkens back to the original Warn planetary winches of years past. It’s a basic design with the gearbox on one end and the motor on the other, and the drum brake is internal to the drum. Everything is held together with small crossbar braces that prevent the two halves from separating. It was the only winch tested with an extended remote-mounted vent hose for the winch motor—a smart addition to help relieve water condensation and increase weatherproofness.

The control box is an externally mounted contactor system. Color-coded wiring makes hookup straightforward, but there is more wiring than an integrated winch. The advantages of a remote-mounted box are the ability to place it in a better location and that less mounting space is required on the bumper. Ironman makes two separate-sized control boxes for different fitments to allow the best mount for your situation. The remote control is intuitive and can be used with gloves. There is a small LED flashlight integrated into the remote. The remote can be used wirelessly with the addition of a small plug inserted into the control box. Ironman provided both control box sizes, so we received two controllers. We did notice that one remote switch felt sticky while operating (likely some plastic flashing in the remote from manufacturing), but after some use felt normal. Both flashlight lenses fell out of the remote during operation, but the flashlight still worked. The wireless operation of both remotes was tested and never worked.

The free spool clutch was the smoothest of all the winches tested. I was impressed at how effortless the rope was to pull off the drum during use, and the rope hook worked well. The initial winch rope was cut from the Jeep’s bumper deflecting, but Ironman provided a second rope. It did not arrive in time, so we finished testing using the MaxTrax UHMWPE rope, which performed flawlessly. There is a quality difference in the fit and finish of parts. The powder coating seems thin and chipped from the slightest impact, and the provided hardware was stamped and didn’t exude confidence, but it should be noted that it did not fail.

During the use of the Monster 9500, the bumpers were more obviously struggling not to bend. The winch design made the system’s flex readily apparent because the twist was severe, but the winch never seemed to struggle. It stalled slightly beyond its rating. Speed was moderate and completely adequate for regular operation.

During the torture testing, the internal drum brake heated up tremendously. The highest temperature of 219°F after the third lowering demonstrates the winch’s inability to lose heat caused from braking. This heat could cause rope degradation if heavy braking is needed in real-world use (most people never lower a vehicle with their winches). The brake was consistent and predictable when stopping.

Pros

- Cost

- Small form factor makes mounting easy

- Vented motor system

Cons

- Controller is flimsy and cheap feeling

- Wireless control system not operative

- Included hardware not well made

$699 | ironman4x4america.com

Warn Zeon 10-S Platinum (Editor’s Choice)

The Warn Zeon 10-S Platinum is the flagship of the Zeon product line, designed to accommodate hidden winch designs and mounts with limited access. I prefer a winch that can be seen and handled manually to allow tending to the rope drum, but my bias does not extend to the winch itself. Warn’s world-class customer service and proven history still set the benchmark all winches are judged against. Fit and finish is impeccable, and the drum design and hardware fitment are top-notch.

With an absent clutch release handle, the clutch is released via the completely wireless remote, activating an internal electric solenoid and, in turn, free spool function. There is no option to plug the controller directly into the winch itself. These two things alone may cause distrust in the product or bring into question reliability, but we did not find fault with either. The wireless remote can be used with gloves and is well-marked. It takes some practice knowing which buttons to use and becoming familiar with the pairing sequence at startup, but both become second nature. The color LED screen provides temperature and charging voltage indications. The remote can activate other remotely operated accessories, such as driving lights, and comes paired to the winch. But if need be, the re-pairing process is simple but requires pressing a button on the winch itself. The controller comes with a cigarette lighter to USB adapter and a heavy-duty, extra-long USB charging cable and can be plugged into the vehicle while operating outside the vehicle while the controller is being charged. The wireless remote range is impressive; I could control the winch from over 50 yards away without issue, and I still had more range.

The Spydura rope is premium quality, but the hook isn’t; the Warn Epic hook should be included at this price. The rope’s red heat barrier indicates when the maximum length is reached, particularly important for hidden mounts. The aluminum fairlead is nicely radiused with good functionality. The rope attachment system to the drum is first-rate, and the finish of the drum surface is designed with just the right friction for the rope to pull well.

The winch body is larger due to the electrically operated clutch system and may be a tight fit for some installations. The hardware is high quality, and having the winch slots accept flanged locknuts is smart. The installation instructions were clear, and the product was simple to use.

During testing, the 10-S performed splendidly, doing everything asked of it without too much fuss. We did not hit the 10,000-pound stall rating during testing, as it stalled at 9,785 pounds, but you’ll likely never use the winch near stall. Its loaded line speed was the slowest of the winches tested, but its unloaded line speed was quicker than most. Free spool difficulty was average, and most users will be able to pull the rope without difficulty. While lowering the vehicle down the hill, heat was adequately managed with the winch’s braking system. Noise increased during braking and rose as the winch gained more heat.

Pros

- Voltage and temperature indications

- Can be mounted in hidden location

- Remote controls accessories, eliminating switches

Cons

- No physical clutch release

- Remote cannot plug directly into winch

- Large form factor requires more space

$2,665 | warn.com

Superwinch SX10SR (Value Award)

Superwinch was founded in 1972, producing winches for recreational and professional uses, and many will recognize the reliable Superwinch Husky found on Camel Trophy vehicles. The US Special Forces have also utilized Superwinch planetary models successfully. In 2019, Superwinch was purchased by Westin Automotive of San Dimas, California. After a rebranded and redesigned product lineup, the SX10SR came to market. Part of the engineering team’s research for the new line included speaking with long-time users and industry professionals to find out what they wanted in a winch, and the results are clear in the SX winches design features.

The SX10R’s solid-state control system and box are die-cast aluminum, bolted onto the winch’s main body. This clever design allows a buyer to relocate the winch control box remotely if the installation requires that. The box has a nicely sealed design with a rubber spring-loaded mechanism. The controller is uncomplicated in that it is labeled “In” and “Out,” and the cable is very robust. The connector uses an easily replaceable metal connector with a distinct locking mechanism to the box, assuring good contact and eliminating accidental disconnection of the control cable. The winch comes with a wireless remote system that is easy to use and was a slightly smaller version of the cabled version. The LED flashlight in the controller is a handy addition for additional light during use.

The rope held up well and appears to be of good quality. The fairlead had a large radius, and the rope hook is a cast version that seemed very strong and up for the task. One additional feature exclusive to the SX is an LED lighting system for the drum. This provides additional lighting for the rope drum and is something that I suspect will be emulated by others in the future.

The clutch release was simple to use, with a pull upward and a twist to free spool. The clutch worked perfectly and never jammed or didn’t engage correctly. The free spool of the rope was easy to pull and would be suitable for almost any user.

During the testing, the winch performed flawlessly. During the stall test, I stopped pulling at 10,190 pounds, and the winch still had more to give, likely another 500-1,000 pounds. The solid housing and gusseted design made the winch very sturdy during use. Its painted coating seems thick and meant to withstand the test of time. Where some other winches tested had visible flex or twist in the body, the Superwinch had none. The heavy-duty body did exhibit a lot of heat retention during use, which could become problematic during strenuous use. The mechanical brake performed admirably while lowering the vehicle, and the vehicle stopped reliably. Line speed was average and provided a reasonable and safe rate while operating.

Pros

- Useful drum lighting

- Metal cord connector locks in place

- Low cost for a high-quality winch

Cons

- Retained significant heat during braking

- Ability to exceed stall rating could exceed some recovery equipment ratings

$764 | superwinch.com

Conclusions

After spending weeks of testing and countless hours pushing the winches to their limits, it’s clear that winches are better now than they were 15 years ago. The industry has managed to produce products that deliver when needed, and there are far more offerings than ever. Any of the winches tested would be suitable for most people’s needs, and the spectrum of price points makes winches more accessible than ever.

Editor’s Choice Award

The Warn Zeon 10-S Platinum takes the award, but my choice deserves some additional explanation. Most winch mounting systems are bottom or foot-forward with a 4.5 x10-inch bolt pattern. It’s become an industry-wide standard and will be the pattern you’ll most likely be shopping for. The 10-S is also available in a corded version with a manual clutch lever, which costs less and is a good option for people with access to their winch. The 10-S Platinum, as tested, will work on nearly every mounting configuration, including hidden mounts, giving it unparalleled versatility.

In my work with Land Rover, the 10-S Platinum was tested and chosen as the factory installation for the Defender. During the testing of different winch installations, Warn was chosen primarily due to its ability to be mounted behind the front passenger protection systems. This meant that the vehicle passed the same crash tests with and without a winch and passed to the same levels. It, therefore, does not require the blanket statement seen on most off-pavement equipment, for “off-road use only.” We’ve since installed a few hundred 10-S Platinums on the Land Rover Trek competition vehicles and have only had a couple of minor problems that ultimately were tracked down as installation issues. I’ve personally had at least 100 pulls with the winches in real-world use and have never had a single issue from the winch or the wireless remote system.

Value Award

The Superwinch SX10SR won the Value Award, hands down. Performance was excellent, and additional features such as the drum light and the option to mount to the control box remotely are fantastic additions. It was evident that Westin Automotive took their time and designed something based on function, but they did a great job with the form, too. Its price point is extremely fair, and the warranty shows the company’s faith in its product.

Takeaways

The winch’s ability to stall is often higher than its rating and presents a real ability to exceed your recovery equipment. The safety factor may be less than you think.

Variables in winch rope quality and size ratings became apparent during testing. Two different 3/8-inch ropes had different diameters and disparities in flexibility. The hidden star of the entire test was the MaxTrax static winch rope. It performed flawlessly on the same mountings that cut other ropes and survived testing on multiple installations and winches. It’s a pre-stressed rope with a protective layer wound around it. Although it’s designed for soft shackle use, it proved to work well on hard shackles, too.

Thermal imaging showed the level of heat and friction from an aluminum hawse fairlead with the rope, leaving no doubt that the rope degrades from the friction. A larger radius fairlead at severe angles helps spread the load over a greater surface area, but the increased surface area increases the friction. The downside to a smaller radius is that it causes the rope strands to bend and ultimately break. Roller fairleads provide the best use but stick out from the bumper and are far heavier. HawsePro recently released a low-profile roller fairlead that has shown to be a good compromise. It allows the advantages of the roller fairlead and has a large radius roller, yet it is small and doesn’t protrude from the bumper excessively.

What setup would I put on my vehicle?” If my mounting system was exposed and I could mount just about anything to it, it would be the Superwinch SX10SR, MaxTrax static winch rope, and a Hawsepro 4 roller fairlead, small in size but with a large radius roller, reducing protrusion from the bumper. That would be the best bang for the buck.

Sidebar

Any electric winch should have a way to disconnect power when the winch is not being used. In a front-end motor vehicle accident, the electrical wiring can easily short or get cut. If the winch is powered on, it can start an inadvertent operation or a fire. Worse yet, it could short-circuit and cause the battery to overheat and potentially explode. I recommend a high-power switch under the hood or a large fuse in the system. Either works well but should be considered a requirement of any winch installation.

Our No Compromise Clause: We carefully screen all contributors to ensure they are independent and impartial. We never have and never will accept advertorial, and we do not allow advertising to influence our product or destination reviews.

Read more: The Art of Winching by Johan de Villiers