Since converting our Land Rover Defender into a camper in late 2016, I have enjoyed almost everything about it, but mainly the space and comfort afforded for everyday living and camping. What we did not enjoy was the vehicle handling after installing a new suspension kit from the now-defunct Bearmach. Body roll was excessive, and the damping performance was inferior, as we discovered, to our dismay, bouncing and swaying our way down West Africa. After installing rear airbags in Turkey, the overall ride was substantially improved, but not sufficiently.

The Bearmach suspension, to its credit, survived that extreme African test but was soon replaced with a set of heavy-duty Terra Firma springs and shock absorbers in Mozambique. Unfortunately, the potholes and jungle roads of Southern and East Africa proved too much for even the Terra Firma suspension, which had served us so well in South America a decade before. And yes, our camper is well within the GVWR most of the time. A front spring collapsed in Zambia, and a rear Big Bore shock absorber broke above the bottom nut in Portland, Oregon. When Nimbus, with offices in France and the USA, reached out to me about testing their new, premium shock absorbers, I was eager but skeptical, as one becomes with age and experience. We have been promised so much from suspension suppliers in the past and have yet to find the zenith of overland suspensions. Our search may be at its end.

After installing the Nimbus shocks and Terra Firma heavy-duty springs in a warehouse in Salt Lake City, we drove to Bend for the Overland Expo PNW. We then made the long trek down through the US (in a stifling, dangerous heat wave) to Mexico before driving the coast up into the South Sierra Madre, 2,000 miles south of the US border. Before I enlighten you with my impressions of the Nimbus Suspensions shock absorbers, let us look at what sets these shock absorbers apart.

Nimbus specializes in advanced oleo-pneumatic suspension systems designed for off-road vehicles like the classic Land Rover Defender, Grenadier, Jeep, Toyota Land Cruiser, and Mercedes G-Class, with new models being developed continuously. The company also develops shock absorption and vibration control solutions for manufacturing and production, heavy machinery and construction, military-grade equipment, and new mobility ventures (think electric vehicles).

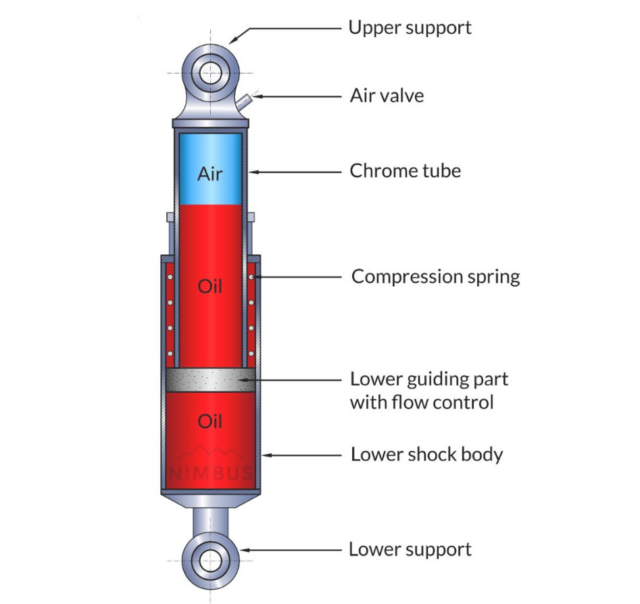

Oleo-pneumatic technology originated over a century ago, and from 1915 to the 1930s, the technology began to play a critical role in the automotive and aeronautical industries. French engineer Georges Messier created the first automobiles incorporating this technology in 1915. Since its inception, the technology has seen significant advancements and remains a preferred solution for managing heavy loads and handling the constant oscillations encountered on rough terrain. Today, oleo struts are still widely used in the landing gears of nearly all commercial and government aircraft, proving the enduring reliability of this time-tested technology.

Nimbus oleo-pneumatic suspensions manage shock absorption by using a combination of hydraulic fluid (oil) and nitrogen gas within a chamber to deliver a ride quality that is both smooth and stable, regardless of the terrain. The gas acts as a spring, being compressed with the oil to cushion the impact from bumps and irregularities in the terrain. The hydraulic fluid is channeled through spring-loaded valves and orifices, allowing the suspension to respond differently based on the driver’s settings. As the oil moves through these controlled pathways, it dampens the motion of the piston assembly, effectively managing shock absorption and recoil. This setup contrasts with traditional air suspensions, which use air-filled rubber or plastic bellows (air springs) along with air compressors, valves, and sometimes electronic controls, as it does not allow for on-the-fly height adjustments. Instead, it focuses on delivering consistent comfort and performance across a wide range of driving conditions.

One of the key advantages of Nimbus’s oleo-pneumatic technology is its adaptability. The suspension system can be fine-tuned by adjusting the internal pressure, allowing users to optimize the ride for different loads or driving preferences without compromising comfort or stability. This flexibility makes Nimbus suspensions particularly suitable for overlanding, where varying terrain and vehicle loads are common.

Another significant feature is the progressive absorption curve of the suspension. Unlike traditional metal springs that offer a linear response, Nimbus’s oleo-pneumatic systems provide a more adaptive curve. This results in a smoother ride at the beginning of the stroke, with the suspension firming up as it compresses further. This design not only enhances comfort but also prevents the vehicle from bottoming out during intense off-road conditions. Nimbus’ suspensions also contribute to improved vehicle handling by reducing body roll and enhancing grip and traction. The system’s ability to adapt to minor road imperfections means that vehicles remain more stable, particularly in challenging conditions like rock crawling or desert racing.

Fully serviceable, Nimbus suspensions are designed with sustainability and durability in mind. The manufacturing process adheres to stringent European environmental regulations, and the long lifespan of the product reduces the need for frequent replacements, further minimizing environmental impact. The components are crafted from high-grade materials, including aerospace-quality aluminum and steel, ensuring the suspensions can withstand harsh environments and maintain their performance over decades. It is recommended that the shocks be serviced, at a cost, once every three years for the replacement of critical components such as oil, nitrogen, seals, and ball joints (ball joints allow the shocks to operate at an angle and are better suited for longevity than standard rubber or polyurethane bushings).

So, how well did the Nimbus shocks perform over the course of our journey to Mexico, and did they live up to the hype? Each suspension system is custom-built based on the vehicle’s specifications and the user’s driving habits, ensuring a tailored fit that maximizes both comfort and vehicle handling.

The shock absorbers had been pressurized specifically for our Defender with consideration of layout, weight, and usage. When we first received the well-packaged shipment from France, I was immediately impressed by the build quality of the shock absorbers, from the exterior construction to the components such as the seals, nuts, and the lower balls joints front and rear. Installation was hard work, but that is because this is a task I perform once every few years. The rear axle had to be dropped significantly to allow the fitment of the rear shock absorbers, which cannot be compressed unless you have a nitrogen-filling system. All the sweat and tears were worth it, though; the Defender looked amazing when back on all four wheels, level and proud (we asked for and received a 2-inch lift). Now for the test drive, the moment of truth.

With a few old suspension bushes replaced to eliminate false feedback, we drove from Salt Lake City to Bend and were instantly impressed by the ride quality. Having driven rough industrial roads to the warehouse for the installation, we had the opportunity for an immediate before and after the test. There was no rebound from the rear over large bumps such as railway tracks, and the body roll at slow speeds had all but disappeared. The next test of the suspension was driving at highway speeds on the I-84, where we experienced sublime comfort and performance. Then, we experienced the twisty mountain passes of the US Highway 20. With my wife dozing beside me, I decided to accelerate into and through the corners between Harper and Buchanan and was amazed at the bulky Defenders’ sure-footedness and lack of body roll. Driving responsibly, I increased the vehicle’s speed through the corners until I found the limit of comfort, which turned out not to be the limit of the suspension but the limit of my now-awake wife’s nerves. Slowing down, I reveled in the fact that the performance of the suspension in the mountain pass allowed me to maintain a higher average (legal) speed, which meant less stomping on the brakes and then working through the gears to keep the turbo spooled up.

After the Overland Expo in Bend, we drove up to La Pine in an attempt to escape the heat wave. The road to McKay Crossing Campground is terribly corrugated; the last time we visited with the Defender and a Range Rover P38, we had to crawl along to avoid our teeth chattering and camper furniture falling apart. With the Nimbus suspension doing its job, the unpaved road, which had clearly not been graded, seemed almost buttery smooth; we could not believe how quietly the old Land Rover glided over the undulating washboard and maintained stability through the corners. To me, a badly corrugated road is one of the most severe tests of a loaded overland vehicle’s suspension, and the Nimbus suspension passed with flying colors. Luisa and I gaped at each other as we glided along with only the worst washboard registering vibration; “That’s incredible,” we thought. Nimbus calls that comfort the “flying carpet effect.”

After driving a thousand miles, my only concern was that the front of the Defender seemed lifted a half inch too much, and the vehicle was not exactly level front to back. I feared that there was too much angular strain on the old but religiously greased front universal joints. A small, high-pressure air pump with a pressure gauge had been supplied along with the shocks. I was able to accurately adjust the compression of each shock via the Shrader valves after a call to Nimbus’ technical guru, Killian. It surprised me to confirm that the Nimbus shocks were, in fact, maintaining the ride height of the vehicle, as opposed to the springs, as after adjustment, the Land Rover sat perfectly level.

I will admit to being skeptical when I was first told that the Nimbus shocks could be used on a vehicle without coil springs and that the shocks themselves could lift or lower the vehicle. This is not the function of even the highest specification shock absorbers, and many of you might doubt this claim. I can attest that the Nimbus shock absorbers do, in fact, lift the vehicle, but I cannot confirm that the vehicle can be safely run on the shocks alone as I have not tested them to that extreme and do not intend to in the near future.

Overall, my experience with the Nimbus Suspension system has been overwhelmingly positive, and my expectations have not only been met but exceeded. The only negative I can think of is that installing the rear shocks is difficult and potentially dangerous without the correct knowledge and tools and should ideally be entrusted to a professional. That said, if you are the kind of person who can afford this suspension and the expensive vehicle under which it will be bolted, you will likely have either the correct tools and knowledge or will entrust the work to a suitable professional.

The little elephant in the room is the Nimbus suspension shock absorbers are quite dear, at around $1,000 each. Is this cost justified? As they are sold with a limited lifetime warranty, custom manufactured with premium materials, designed to last a lifetime, and need only be serviced every three to five years (depending on usage conditions), the Nimbus shocks are well worth the investment. I believe that I have finally found the optimal suspension setup for my hard-working Land Rover, and I intend to retain this suspension configuration for the vehicle’s lifetime.

Read More: SUV, Van and Pick-Up Camping Conversion Kits :: Buyers Guide

Our No Compromise Clause: We do not accept advertorial content or allow advertising to influence our coverage, and our contributors are guaranteed editorial independence. Overland International may earn a small commission from affiliate links included in this article. We appreciate your support