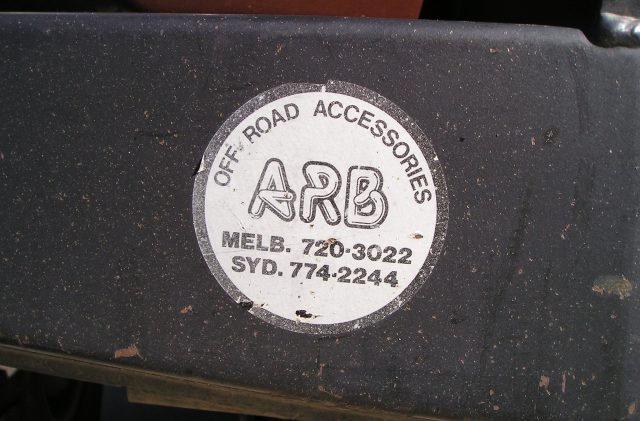

The year was 1975, and on the horizon a travel worn Land Rover sent clouds of dust swirling into the air. Behind the wheel, an off-road enthusiast by the name of Tony Brown shifted gears, while mulling over a very big idea. You see Tony was fed up with the sub-par standards of Australian four-wheel drive companies. Their hastily designed products were ill suited to the long corrugated roads of the outback, and many of their bull bars and roof racks simply fell apart over time. As he repeatedly worked to repair his own vehicle and improve their designs, his experience grew, and so did his reputation among enthusiasts. Then on a lonely trip through Australia’s top end, it dawned on him. Maybe he could build a better line of products. It was a daunting concept, but as he made the drive back to Melbourne, Tony decided to take a leap of faith and start his own company. The idea was simple; deliver high quality, durable products. Something that he would be proud to put his name on. In fact, that wasn’t a bad idea. He would use his initials as the name of the company; Anthony Ronald Brown… ARB.

Fast forward forty years, and Tony’s garage based startup has exploded into Australia’s largest manufacturer of off-road parts. Their products are sold and distributed all over the world, and their reputation for quality is better than he could have ever hoped for. Our team alone has been running their deluxe bars for over a decade, so we figured it was about time to take a closer look at these legendary products.

The Makings of a Bull-Bar

If you really want to peer into the life cycle of an ARB bumper, you’ll need to leave the factory and head over to where the real magic begins: R&D. Before the first piece of steel is ever cut, engineers gather here to pour over vehicle specifications, evaluate safety data, and develop testing models for new products and ideas.

“To ensure our products consistently meet your expectations, ARB invests substantial capital into research and design each year. Our design and engineering team utilises the latest CAD, CAM parametric modelling systems and finite element analysis packages, and is supported by independent companies and universities for special projects like vibration, strength and crash testing.”

Once their development team gives the go ahead for production, the design is uploaded to ARB’s manufacturing facility where a system of advanced fabrication equipment is waiting. The process begins with an automated laser which makes cuts as small as .008” in the steel. This prepares the sheets to be folded up to five times on a CNC (Computer Numerically Controlled) machine for additional strength during impacts. Afterwards, the components are moved to the welding stage. Here a series of robotic welders and grinders take care of the repetitive processes, while experienced employees tackle the specialized ones. This ensures a polished and visually appealing look every time, with an extra layer of human quality control.

After all of the components have been assembled and checked, the bumper is blasted clean, and then enters a chemical bath before being powder coated black. The video below shows the entire process in just a few minutes, and I would highly recommend checking it out.

Installation

Over the years our team has installed ARB bumpers on Land Rovers, Toyotas, Jeeps, Hummers, Fords, Nissans, Dodges and more, so it’s safe to say we’re becoming old pros at it, but you certainly don’t need to be. I installed my first ARB bull bar at 19 years old without help or any real mechanical experience, so I would say that they are one of the easier accessories to do at home. In fact, our latest install was so straight forward I thought it might bore you, so we’ve decided to skip the step by step walk through and list a few tips instead.

- Installing one of these bull bars is best done with a friend. Even if you have some sort of hoist rigged up to hold and lift the bumper, positioning it is much easier with a second pair of hands.

- ARB designs some of the best products on the market, but their instructions are about as clear as mud. If you can’t figure your instructions out, don’t panic, chances are that someone else has posted a video or walk through online. Read your instructions all the way through, and then consult the oracle (google) if you have questions. Remember, DO THIS BEFORE YOU BEGIN. It pays to be prepared here, as you can’t drive to the store once the front end of your truck is torn apart.

- Leave the protective plastic on the bumper as long as possible. Someone will end up leaning against the bull bar with their belt, scratching it with a tool, or setting it down and scuffing the surface. On this same note, lay some old blankets down in front of the truck to set the bumper on before you begin. You will probably need them for prep, or just to lay on while you wrench. As you can see from the photo above we ignored our own advice during the last installation, and I assure you we paid the price with several scratches.

- If you’re installing the bumper on an older vehicle, plan to scrub and clean the vehicle surfaces after removing the old components but before installation of any new ones. Dirt, rust, and road grime will not be pleasant as they fall into your eyes during the install, and they can cause additional wear if bolted down between surfaces.

- Try to place as many bolts and nuts as possible before tightening fully. Generally our bumpers have always lined up, but occasionally there is a bolt hole slightly askew, and this extra movement could be the difference in making it fit. If the hole still doesn’t line up with lose hardware, try using a mallet or lever to re-align it, and as a last resort, drill out the edge with a bit the same size as the bolt.

Field Performance

There are two ways to test a product. One method involves careful evaluation and measurements in a laboratory setting. The other is more of a sink or swim approach; toss it into the grit and stress of a real world situation to see if something breaks. You can guess which method we prefer. Over the last ten years our ARB bull bars have seen serious use on all seven continents, including winching, vehicle recoveries, and even a few animal strikes, and these experiences have taught us a lot about the strengths and weaknesses of these bumpers.

Impact Protection

Unsurprisingly, the biggest benefit of an ARB bumper is improved safety for you and your passengers, which is achieved in three main ways.

- First and foremost, the reinforced design protects the radiator, engine, and other vital components from damage in the event of an animal strike. This greatly reduces the chance of you being stranded with a disabled vehicle in some remote corner of the world.

- Second, the bumper is shaped to push an animal or other object underneath and to the sides of the chassis. This discourages any debris from rolling up onto the hood or into the windshield, where it could potentially harm the driver or passenger.

- Finally, ARB designs each one of their bull bars to match the vehicle’s factory crush rate, and then tests them in actual crash labs. This is ARB’s trump card in the world of bumpers. Instead of throwing a mess of steel onto the front of your truck and hoping for the best, their engineers work tirelessly to retain the critical crash pulse matched to your airbag system, thus eliminating the chance of an unnecessary or failed deployment.

That all sounds fantastic, but does it actually work in the field? Thankfully, yes. Our team has accumulated all sorts of tales through the years, from other drivers hitting us head on, to unexpected wildlife in the mountains, and each time these bumpers have stepped up to the challenge and kept us safe.

Trail Use

Of course everyone talks about safety with ARB, but there are other benefits worth mentioning. For starters, most vehicles receive a significantly better approach angle thanks to the bumper’s shape. Our Ford Excursion was instantly transformed from a soccer mobile into a trail worthy truck by removing the stock bumper and lower fascia. We’ve also found that when the additional clearance doesn’t quite cut it on the trail, these bumpers can take a decent rock hit without bending or breaking. They aren’t bed lined though, so the paint will definitely suffer. If you’re building a dedicated trail rig and simply want maximum clearance, a slim line or tube bumper would probably be a better fit.

Now I’ve heard all sorts of stories over the years about ARB bumpers tilting or shifting during heavy recoveries, so this was a big test point for us. We winched out rolled vehicles, pulled trees off the road, used snatch straps on full-size trucks, and even jacked up the front end of a land cruiser from the bumper without issue. Maybe we got lucky, but thus far our test units proved sturdy time and time again.

Accessories

There are two reasons to buy a bull bar. One is protection, and the other is to mount accessories, and the ARB is excellent for both. The center of the bar features four tabs on which you can bolt on auxiliary lighting, antennas, or tools like a jack or shovel. We usually choose to install a set of spot and flood lamps, which improves nighttime visibility and gives us the best chance of seeing an obstacle before it becomes a problem. Depending on the model of your bumper and the year of your vehicle, you may also have options for integrated turn signals or fog lamps. If this is the case, we’d recommend soldering your own connections or at least using heat shrink butt connectors. The supplied electrical connections from ARB will work, but they aren’t durable enough to weather the elements, and you’ll soon find them wearing out.

The biggest accessory point on this bumper is the winch mount, which is located inside the center of the bull bar. Since each bumper is designed for a specific vehicle, the size of the winch accommodations will vary, but we were able to tuck a WARN 16.5 inside our Excursion without issue. Operating the clutch is easy thanks to the spacious access holes, and I love the recessed control box mounts like the one shown below.

The Drawbacks

Despite its many advantages, the ARB bumper doesn’t get away scot free. The same materials and design techniques that make it so safe and durable also make it heavy, and that has several drawbacks. Chiefly, it decreases the fuel economy of your vehicle and therefore the total range. By just how much varies greatly depending on the weight of your stock bumper and lower valance. On some newer trucks and SUVs, the factory plastic bumper weighs almost nothing, so adding a steel bar is a big weight increase. On our excursion however, the stock steel brackets and heavy chrome bumper were almost a wash with the ARB, so we didn’t see any real variation in fuel economy.

There are also adverse changes to handling, especially in turns and while braking. This is more prevalent when running a winch and bumper on stock suspension, but any addition of weight to a vehicle can changes its performance. We’d recommend installing an aftermarket suspension to help compensate for the additional load.

After more than forty years of production, I’d say ARB is still delivering on Anthony Brown’s original promise of building “high quality, durable equipment that meets the vigorous demands of 4WD owners”. Whether I’m in the city surrounded by inattentive drivers, or deep in the wilderness with deer charging onto the road, I feel safer knowing that their years of research and development are protecting my family should things go wrong. Like life, adventure is rarely predictable, so it pays to be prepared for the road ahead.