In this installment of the Expedition Portal series on brands that inspire us, Senior Editor Ashley Giordano profiles the multi-generational Denmark-based storage company AluBox. She connected with Søren Wiberg to learn more about AluBox’s origins, its involvement in field expeditions, and how consumer preferences have changed since the company’s inception in 1999.

Cover photo courtesy of Clay Croft, Expeditions 7

I’ve come to Iceland’s Vatnajökull National Park by Zodiac boat to lands that were once buried beneath Europe’s largest glacier. This pristine wilderness region has seen little to no trace of human activity. But here I am, enjoying a hot cup of Yorkshire Gold tea, examining the tiny Arctic plants, and watching icebergs float past.

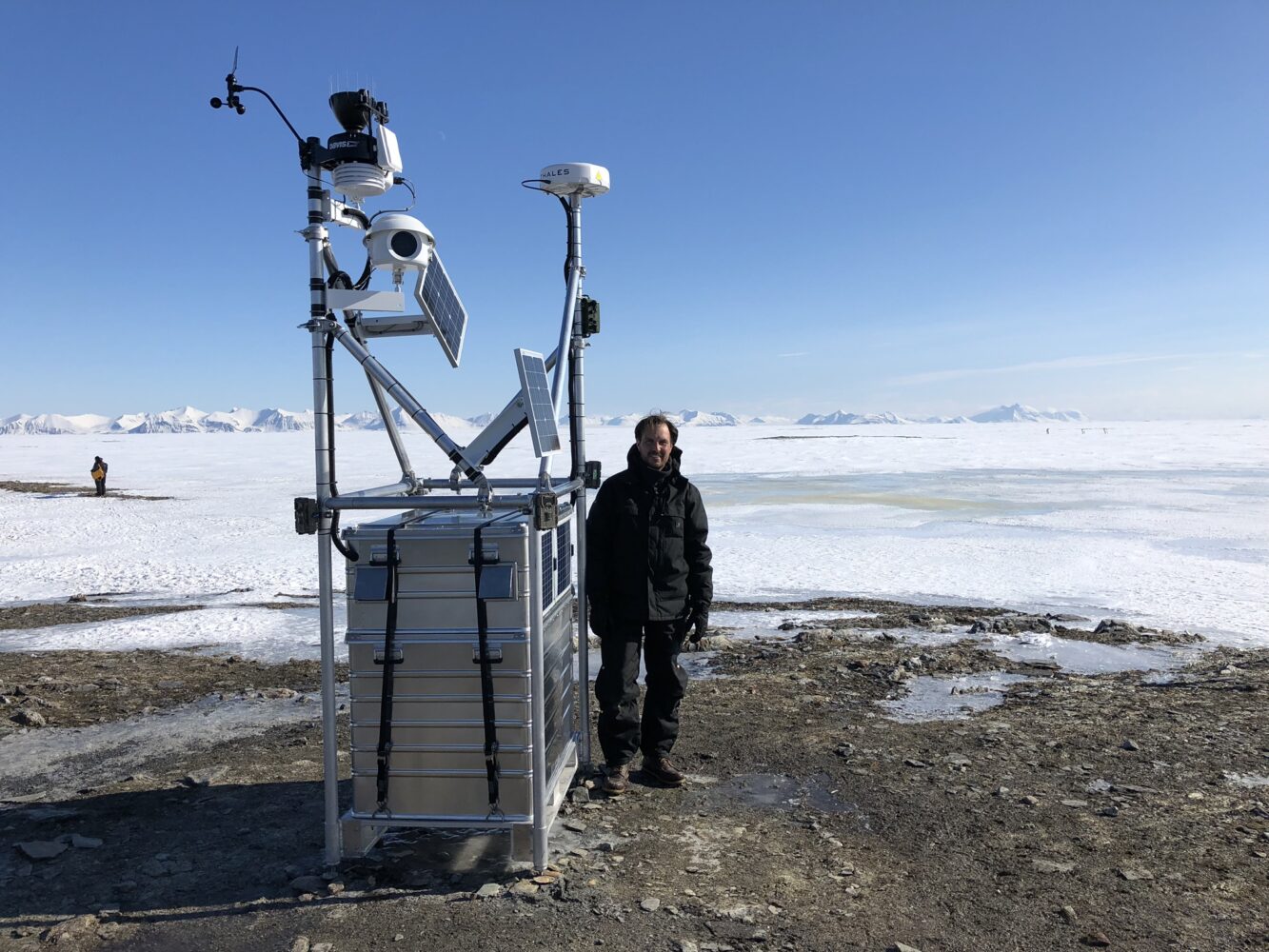

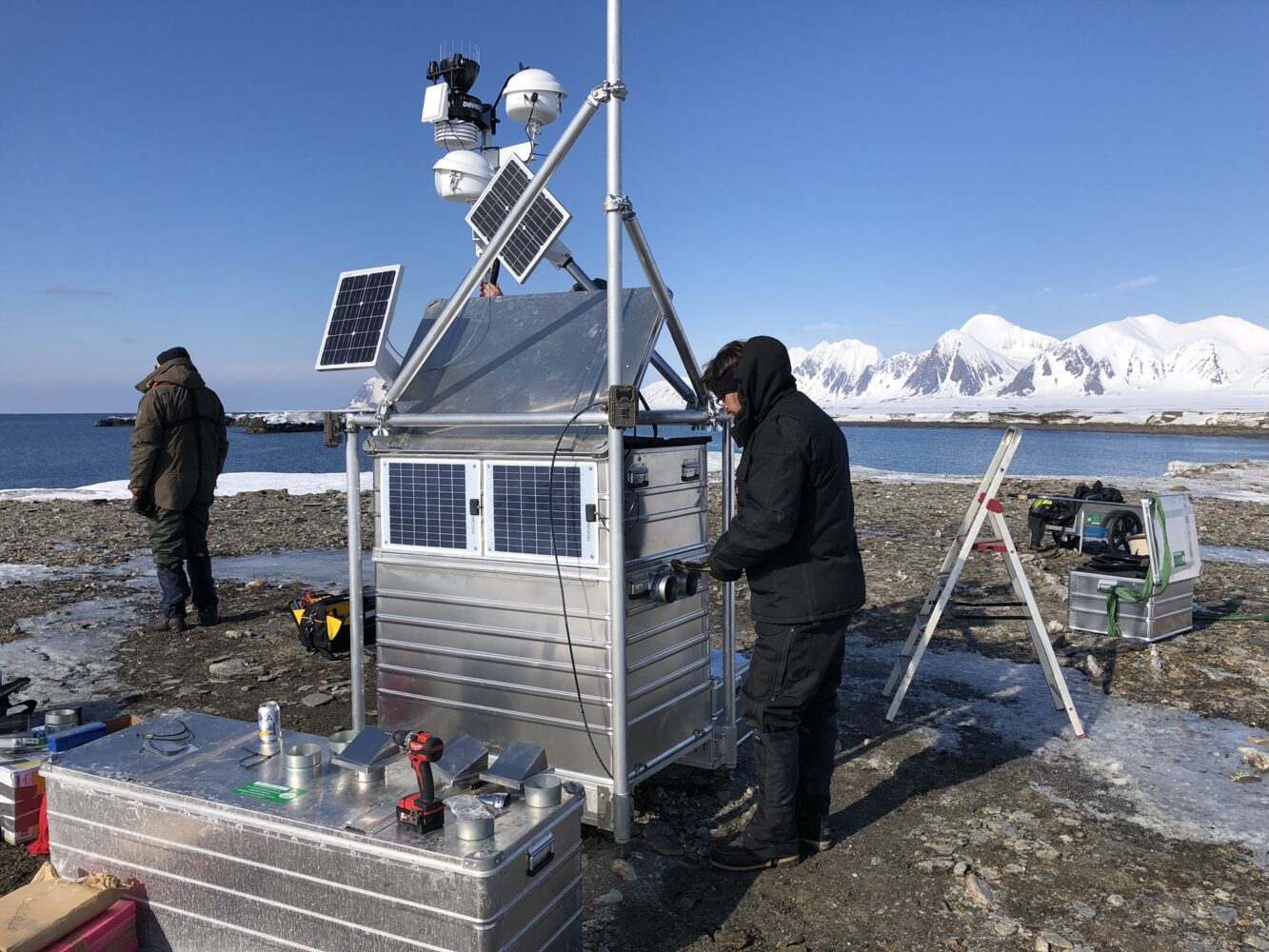

Behind me, however, a group of researchers tinkers away, constructing a small field station made of aluminum boxes. I didn’t expect to see the familiar silvery cases out here—I’m used to seeing them on vehicle roof racks or stacked in the back of trucks. I’ve lifted them, refilled them with breakfast foods and snacks, and reached to unlatch them on many trips.

But in Vatnajökull, they’re equipped with solar panels and devices to monitor the landscape biosphere, including wildlife, weather, vegetation, and atmosphere, with minimal human impact. This field station, made from AluBoxes, will help us learn more about the planet. How cool is that?

AluBox began in Denmark and was born from Ole Wiberg’s desire for a lightweight transport and storage solution for his Land Rover. Twenty-five years later, the company is now in its third generation and continues to grow and develop, addressing the needs of overland travelers, researchers, expeditions, and military, police, and rescue services. Intrigued by this journey, I connected with Ole’s son, Søren, to learn more about the company’s origins and plans for the future.

How did AluBox begin?

We are a family company that has traveled extensively with our own Land Rovers since the 1980s. Adventure is a part of our DNA; we have always traveled with our own vehicles, our own equipment, and our own family. Our first rooftop tent was an old Danish-made rooftop tent from the ’80s. Back then, rooftop tents were rare in Scandinavia and always attracted a lot of attention.

After a long period, our old Danish rooftop tent became so worn out that it unfortunately had to be replaced, and we then fell in love with an Eezi-Awn rooftop tent. As we accumulated more and more equipment for overlanding, we became aware that there was not much gear available for purchase in Scandinavia. Therefore, we began importing various equipment for overlanding and expeditions.

Initially, we started importing rooftop tents and other types of expedition equipment, but we also realized that storage was a significant issue for our expedition friends. One of the most important pieces of equipment when traveling is storage. For many years, we traveled with wooden boxes and plastic boxes. However, we had never been completely satisfied with them, especially because they were heavy and not waterproof, and therefore not suitable for placing on the roof. The solution to this was to start designing our own boxes. We looked at several solutions and materials. The choice fell on aluminum with rubber gaskets. We came up with a design that closely resembles our current design.

These boxes were greatly admired by other outdoor enthusiasts. Therefore, Ole (first generation) and Søren (second generation) decided to put these Danish aluminum boxes into production and fill the gap for waterproof transport and storage boxes. In the following years, the company grew and developed significantly. The latest development is that Peter (third generation) has joined the company. It is an incredible joy that this year, we can celebrate our 25th anniversary with three generations in the same office.

Photo credit: AluBox

What is the story behind the very first AluBox product?

The first box we designed is our A042. It was specifically designed to have the same height as our first rooftop tent, and its footprint is designed to fit as a quarter pallet in the Euro pallet system. Although we now have more than 30 standard sizes, this A042 model remains our most popular model.

From day one, we have always relied on aluminum; it is perpetually recyclable, our alloy is saltwater-resistant, and it is a lightweight and durable material that is perfect for all of our expeditions.

What are some challenges you’ve had to overcome along the way? What successes are you most proud of?

Our product is the result of constant development. All our best innovations stem from something we were not satisfied with and, therefore, improved. Our locks started as ordinary standard locks from stores, and since then, we have upgraded them several times. Today, we manufacture them ourselves.

The first boxes had a gasket glued in the lid. Since then, we have chosen a solution that allows this gasket to always be replaceable if necessary. It is important to us that future generations can also enjoy the boxes their ‘ancestors’ bought.

We have decided that every major change in our boxes should be visible without opening the box. This way, one can see if their box has the new features and also identify its production year. After the first few years, we changed our logo from Wiberg-Wiberg to alu-box.com, which marked our significant upgrade of locks and hinges. A few years later, we changed it to alubox.com without a hyphen. This change coincided with the launch of our new patented bottom profile.

Photo credit: Søren Wiberg

AluBox has been involved in many research projects and expeditions. What extreme conditions have the boxes been subjected to, and how have they been used in a scientific expedition setting?

There are bears in a large part of Scandinavia. Over time, we have had customers, especially from Sweden, who have had experiences with bears trying to take their food from our aluminum boxes—unsuccessfully. This led us to get the boxes officially “bear-proofed,” so our customers can store food in the boxes in areas where this is required. Our boxes were tested in Yellowstone National Park by the much larger bears there. We subsequently had these aluminum boxes sent back to us, and today, they hold a place of honor in our office.

The most extreme conditions our boxes have endured have been “the test of time” over the last 25 years. Not long ago, we attended a Norwegian overlanding fair, where we met members of the Norwegian Land Rover Club. On top of their vehicles, they had some of our original boxes that were nearly 25 years old. They proudly told us the boxes had been on their roof racks since they bought them and were still used on all their expeditions. Our goal with AluBox is to create boxes that you buy not only for yourself but also for the next generations.

A side effect of constantly focusing on quality is that we have become the preferred supplier of aluminum boxes to the military, police, and rescue services. Our aluminum boxes are also military-graded. The industry has long since discovered that we deliver boxes of the highest quality, so today, a significant portion of our production includes boxes in various designs. The interesting thing about our industrial customers is that they often request customizations, which often require us to think creatively to develop new solutions.

Photo credit: Søren Wiberg

Some years ago, we were contacted by the IK Foundation. They needed aluminum boxes to store the original travel documents of Carl Linnaeus and his apostles, who traveled around the world in the 1700s to collect scientific information. The IK Foundation also needed a field station developed. In close collaboration with the IK Foundation, we developed an autonomous micro field station system to observe biospheres without disturbing nature. It is designed to be flexible, field-dignified, and robust. This platform for scientific observations and documentation of a landscape was developed by a group of international specialists. These field stations are set up in some of the same locations that the Carl Linnaeus apostles visited on their many journeys.

We travel around the world setting up these field stations. Our first expedition went to Svalbard (Spitsbergen), [Norway], where we set up a field station in a place rarely visited by humans since the first visit in 1758. Here, the task over an entire year was to document the unknown wildlife in this remote location. It was a great success. We were the first to observe polar bears at this site. As an extra “bear-proof test,” our field station and aluminum boxes were attacked by a hungry polar bear. The bear did not succeed in breaking into the boxes, which we are proud and happy about. We managed to get a selfie of the polar bear with one of our onboard cameras.

Traveling in an entirely open and snowy landscape where there is a risk of encountering polar bears is a unique experience. It also means that you must constantly have armed expedition members on watch, which can be especially interesting at night.

Currently, our field station is set up on the southeastern part of Iceland. It has been there for several years, observing the movement of ice on Europe’s largest glacier. We had the pleasure of being visited by XOverland during their extensive journey around Scandinavia.

What trends or consumer preferences are you seeing these days? Have client desires changed since you began production in 1999?

Our customer base has increasingly shifted from people who “just needed a storage box” to a group seeking a durable and sustainable product. One of our main focuses has been on making our products environmentally friendly. A significant portion of our aluminum is recycled.

Another trend among our customer groups has been a greater desire for accessories. We recently launched our AluBox coffee kit, which offers our customers several different options for their boxes. It includes a side table, case tops for the box itself, an interior lid MOLLE panel, and more. We have also launched RuumX, a flexible divider system for AluBox that allows users to keep items secured exactly where they want them.

For many years, people had to use straps or bolts to mount our boxes. Recently, we developed a completely new system of mounting brackets to secure our boxes on roof racks and roof bars. They fit most models of roof racks available on the market today.”

Describe one of your most memorable overland trips.

Our production of aluminum boxes takes us to many places around the world when we visit our dealers. Here, we have many unique experiences with people who are passionate about overlanding, expeditions, and adventure. It is always wonderful to meet like-minded individuals and experience the parts of the world that are their favorites.

Back in 2000, we went on an expedition with Land Rover around the northern part of Africa and the Sahara. It was easier to travel around back then than it is today. We had an amazing trip. There is a special feeling of being alone in a sand desert, which is so different from what we usually experience. The world looks different when you lie in your rooftop tent and look out over a sand desert illuminated by a full moon. In the desert, we had the first chance to properly test our aluminum boxes in high heat and dust. We went through several sandstorms, and it was here that we realized how important it was to develop our boxes to withstand these conditions and what needed to be changed to make them work optimally.

Our boxes are still tested frequently in the desert and sandstorms, as we have become the main supplier of aluminum boxes for the historical-based long-distance rally, The Real Way to Dakar, that every year takes the participants through rough, difficult and varying terrain with their vehicle from Paris in France to Dakar in Senegal. We really appreciate this opportunity to get customer feedback from some of the roughest use of our boxes.

Today, we send our aluminum boxes to all corners of the world. We know that many of these aluminum boxes will be involved [in] years and years of adventure and will see more of the world and experience more adventures than we ever will.

Some of our customers are sending us stories and pictures from their adventures. Furthermore, we hope and encourage all our customers and the future owners of our AluBoxes to share these stories and pictures with us. We will really enjoy it.

Today, with three generations involved, it is an even greater joy to hear all these stories, but also to go on our own expeditions and pass on experiences and knowledge to our future generations.

Our No Compromise Clause: We do not accept advertorial content or allow advertising to influence our coverage, and our contributors are guaranteed editorial independence. Overland International may earn a small commission from affiliate links included in this article. We appreciate your support.