Suspension is the foundation of any overland vehicle build. Its purpose is to manage the additional payload of tents, campers, armor, and other accessories. Although factory springs and shocks will likely provide a more comfortable ride and last longer than aftermarket components on a stock truck, they were not designed to manage the weight of a vehicle nearing its gross vehicle weight rating (GVWR) for extended periods.

The Factory Race series Fox 2.5s currently installed on our 2008 Toyota Tundra TRD Off-Road showed us how much of a difference good-quality shocks can make to a truck. They opened our eyes to the on-road comfort and off-pavement performance possible with a good quality bolt-on shock. The current springs (600-pound/inch Eibach coils up front and Old Man Emu medium-duty leaf packs out back) worked perfectly with minimal additional weight up front (a CBI Off-Road Fab full-length skid plate) and up to 600 pounds (a Go Fast Camper V1 and camping gear) in the bed of the truck. These shocks inspired us to put long-travel suspension on our 1990 Toyota Pickup.

Although we have done our best to keep the current shocks and shafts clean, they still take an absolute beating on Albertan highways and backroads. Per the Fox service interval matrix, we have checked and increased nitrogen pressure frequently (every 10,000 kilometers), and the two rear shocks required a complete shock service after 30,000 kilometers.

None of this maintenance is a shock (get it?) and is simple to do in a clean, warm shop in the middle of Calgary, Alberta—especially with rebuild kits, oil, and nitrogen on the shelf. However, our new plan is to travel long-term out of the Tundra. This means that the less time spent on maintenance, the more traveling we can do. A basic twin-tube shock such as an Old Man Emu Nitrocharger can last hundreds of thousands of kilometers without any maintenance, but we have become accustomed to the off-pavement performance that a performance shock provides. Finding dampers that are a compromise between the two is key: enter the ARB BP-51.

What are ARB BP-51s?

The Fox, King, and Icon shocks that you’ll see on many off-road builds (including two of our trucks) came from the racing industry, whereas ARB designed and built the BP-51 from the ground up as a performance shock for overland use. That means it will perform well on and off the pavement while withstanding the rigors of long-term, long-distance travel. The three-year 60,000-kilometer warranty shows that ARB stands behind this.

BP stands for “bypass.” Unlike advanced racing shocks that have external bypass tubes but are very similar to shocks you’d find under a Ford Raptor, the internal bypass shocks provide position-sensitive valving. This increased level of damping at the end of travel helps prevent harsh bottoming or topping out of the shock, while providing a comfortable and controlled ride during normal driving conditions. The BP-51 shocks and remote reservoirs are built with 51-millimeter aircraft-grade 6061 aluminum. The anodized finish helps fight corrosion, while the oversized lower spherical bearings and rubber bushings increase durability and keep unwanted noise to a minimum.

Unlike most of the shocks that have come from the desert racing market, BP-51s not only allow for compression adjustment but also rebound. Adjustable rebound is important when tuning suspensions having high spring rates. Heavy trucks require stiff springs to support the payload, but those same springs unload with greater force. These BP-51 shocks allow for rebound control to match the payload and spring rate.

The Fox 2.5 shocks that are coming off of this truck have larger diameter shock bodies and larger shafts which can equate to additional strength and greater damping abilities. Trading some of that potential performance in exchange for longevity is the goal, all while adding additional tuning options.

Upper and Lower Control Arm Considerations

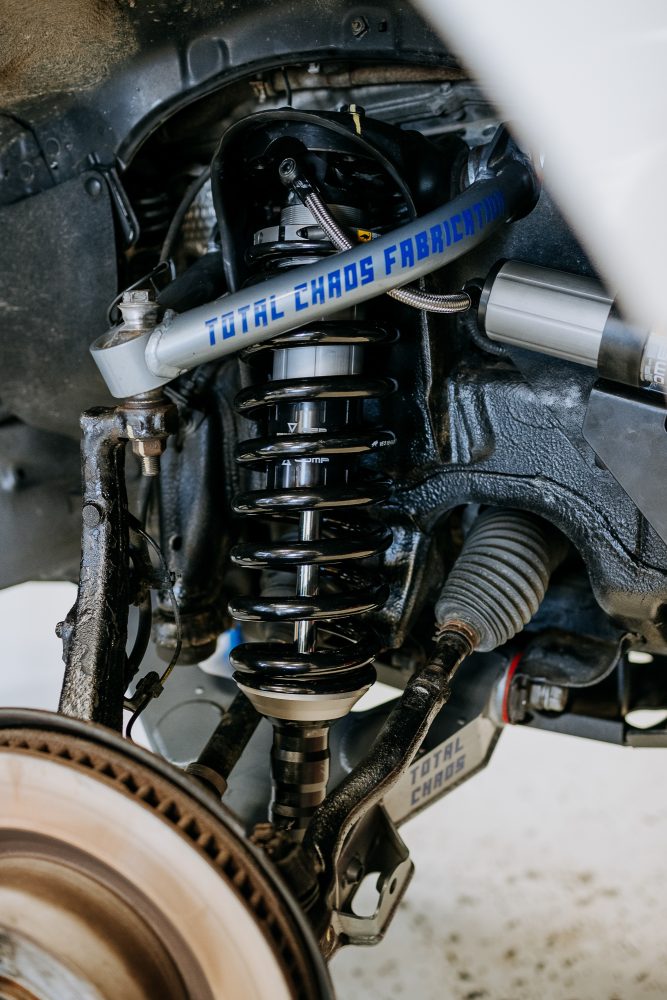

We are keeping quite a few suspension components from the previous build. The Total Chaos Fabrication upper and lower control arms allow for greater wheel travel than stock and precise alignments. Although they do require occasional greasing of the polyurethane bushings, it’s not any more frequent than the other serviceable chassis components, and the control arm stability provided by those bushings is welcomed when driving a large truck. The added caster achievable from the control arms enables precise alignments on a lifted truck. It’s inevitable that the uniballs will make noise (and require replacement) in the future, but I have had great luck with the set that we originally installed. To this point (after three years and 40,000 mostly Canadian kilometers), they are still in good shape and don’t make any noise. A pair of uniballs and a removal tool will remain in the truck; if any of the four identical uniballs need replacement, it’s a simple task to swap them out. For the time being, we left the Old Man Emu medium-duty CS055 leaf springs connected to the chassis with the OMEGS22 greaseable shackle kit.

Installation and Initial Impressions

We added the 25 millimeters of preload to the driver side front coilover and 20 to the passenger side. This compensates for the future weight of the C4 Fabrication front bumper, Warn VR 12-S winch, and a Transfer Flow long-range fuel tank on the driver’s side. Rebound and compression, front and rear, remain at the as-delivered settings to start. We’ll make changes to the preload if necessary once all of the weight has been added to the Tundra.

As the weight of the truck increases, we’ll encounter more and more roll in corners. To counteract that, I installed a Genuine Toyota TRD sway bar, new bushings and hardware, and used Total Chaos end links.

Off-pavement, these shocks remind me of the Old Man Emu Nitrochargers that were on this Tundra before the Fox 2.5s. They’re firm yet compliant and quiet. The BP-51s don’t inspire as much confidence as the Fox shocks on large G-outs or at speed on corrugations for long periods of time. Initially, I found that the shocks were topping out very easily, but adding several clicks of rebound control solved that issue. Adjusting the shocks with the included tool is definitely more difficult than the Fox DSCs (or equivalent 2.5 performance shocks) that have an adjustment on the reservoir, but in reality, these BP-51s will probably only get tuned again after the camper (and a set of Deaver leaf springs) get added to the truck. Overall, they landed as expected in between a good twin-tube shock and a performance 2.5 shock.

Wheels and Tires

Selecting tires is an important consideration when building an overland vehicle. We chose a 35×12.50R17 Load E tire because it’s fairly easy to find worldwide and also fits in the factory spare tire location. We moved from a Toyo Tires Open Country MT to an AT3 for two reasons. One, to reduce weight (saving 18 pounds per corner), and two, because an all terrain performs much better in winter driving conditions. We wrapped the AT3s around Fifteen52 Traverse HD wheels.

As payload increases further, we’ll have to make additional changes to the suspension to compensate. A Hellwig rear sway bar, Timbren SES bump stops, and Deaver leaf springs are all on the shelf, ready to be installed.

Our No Compromise Clause: We carefully screen all contributors to ensure they are independent and impartial. We never have and never will accept advertorial, and we do not allow advertising to influence our product or destination reviews.

Read: 2008 Toyota Tundra TRD Off-Road Staff Project Vehicle Introduction