Editor’s Note: We elected to feature this editorial as a service to our readers, recognizing that so few of us know the dangers of asbestos in older vehicles, often encountered during the restoration process.

The Jeep is without question the original off-road vehicle. Still today, all kinds of Jeeps are highly sought after. Whether to be used as daily drivers, modified as rock climbers, or ready for mud-covered trails, the vehicle has maintained its appeal and reputation for reliability among its community. Enthusiasts love them all (except that square headlight YJ), from the original Willys-Overland MB Jeep to the Classic CJ and YJ. Many aficionados take the time to restore old Jeeps to their original glory. We’d like to discuss the history, admiration, and some potential hazards of restoration.

Jeep Origins

The Jeeps we know today have gone through many changes over the years. Born out of military necessity and transformed for civilian life, it was one of the first vehicles that could be taken where no other could go.

Back in 1940, the US military sought a new kind of vehicle (to replace horses) that could maneuver over rugged terrain but remain light enough for transport. A request for 1,500 prototypes to be tested was sent out by the US military. Automakers only had 75 days to get their designs and vehicles in, and a small auto manufacturer, the American Bantam Company, was the only one to make the deadline. Originally named “the blitz buggy,” the new vehicle was a hit and exactly what the military needed. Willys-Overland and Ford Motor Company submitted designs as well, based on the Bantam design, and the Willys-Overland body won the hearts of the committee.

The military contracted all three companies to build the Willys jeep. Willys-Overland made more than 300,000, Ford Motor Company made over 200,000, and the original designer, Bantam, only made a little over 2,000. More than 640,000 Willys MB jeeps were produced during WW2. A Willys-Overland motor provided 60 horsepower and could move the vehicle at a cruising speed of 45 mph—this was considered relatively fast for vehicles at the time.

The Willys-Overland MB jeep was the first four-wheel-drive vehicle and utilized the newly invented power transfer case, created by Borg-Warner in 1940. If the military couldn’t take the time to repair jeeps that had broken down in fields and forests, they were left behind. The remaining jeeps in Europe following WWII were often repaired by farmers to be used for numerous tasks. The Willys MB was, in many ways, Europe’s first tractor, and helped to recover the European economy in the wake of destruction from the war.

As troops returned to the States, those who drove jeeps during the war wanted to have one at home. The Willys-Overland company owned the rights to the design, and in 1943, two years before the war ended, they were already working on the first CJ or civilian jeep. The CJ-2A rolled out in 1945, and Willys-Overland made 214,000 CJ-2As through 1949. Many models were to come after the success of that first CJ. The rights to the jeep changed hands numerous times, all the way until it was rebranded with a capital “J” to become what it is today: Jeep.

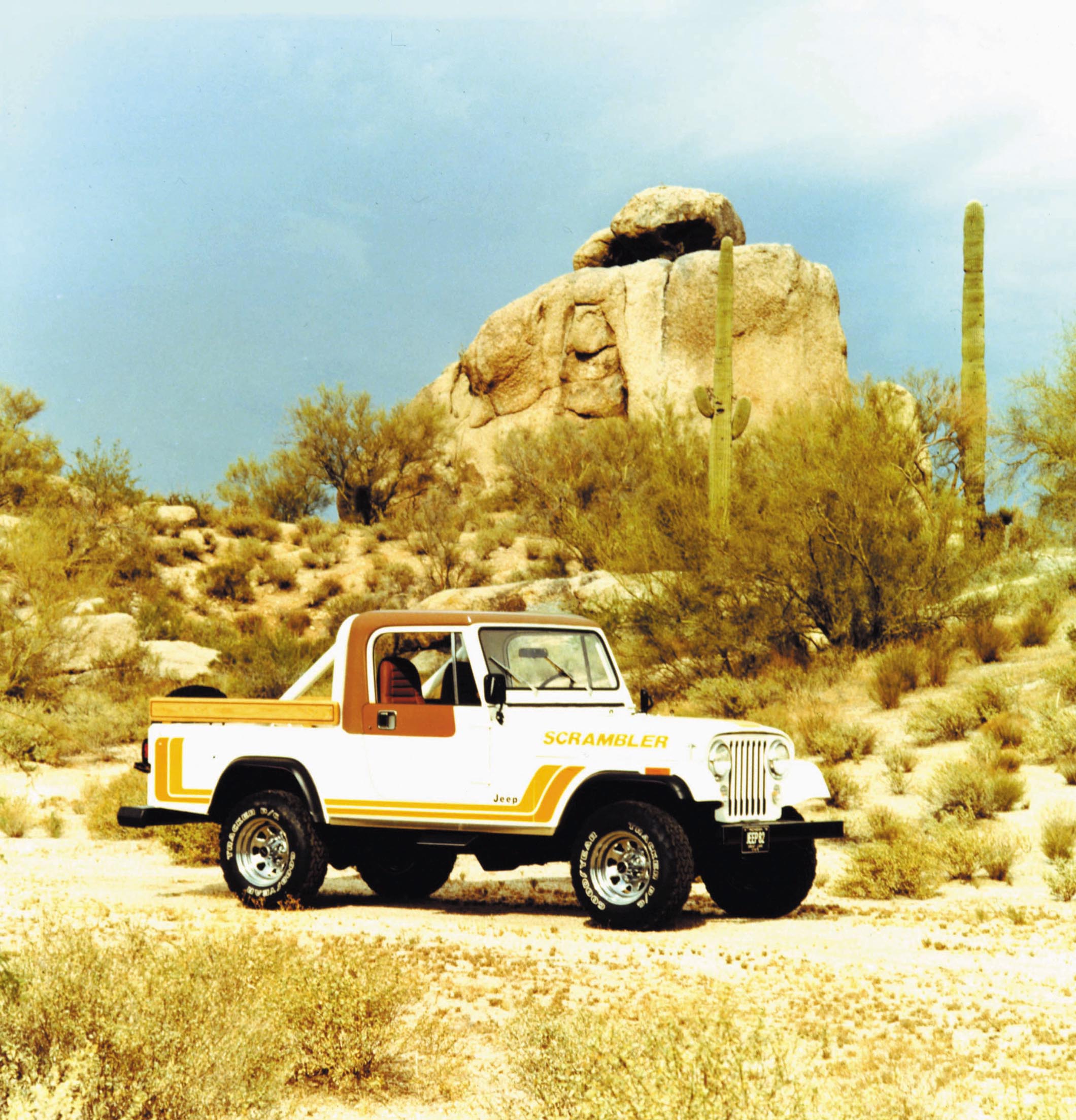

Even the publisher of Expedition Portal spent decades driving and restoring Jeep vehicle. He noted that there was no information or awareness around asbestos. His 1983 Jeep shown here.

The Jeep Lives On: Restoration of Jeeps Today

The Jeep is still a highly desired off-road and overland vehicle today. There’s nothing more iconic in the community than the Jeep Wrangler. Many find the older models to be more suited and stylish than newer versions, or it may be that these Jeeps are nostalgic for many. These classic models are even respected in the “Jeep wave” community. It’s my understanding that the owner of the oldest Jeep is supposed to wave first when passing.

Restoring an old Jeep to its original glory is a time-consuming process, but the results are sure to make heads turn. However, when restoring old Jeeps, there are some hazards to consider before starting a project.

Before the 1980s, many automotive parts were produced with asbestos due to its availability, unmatched strength, and durability. Unfortunately, manufacturers were putting many mechanics, military personnel, and do it yourselfers in harm’s way as exposure to these fibers can lead to significant health issues. Asbestos is a known carcinogen, and exposure can cause serious respiratory illnesses like asbestosis as well as lung cancer and mesothelioma. While car parts containing asbestos have been largely phased out, automotive industry workers and at-home mechanics still need to be aware of these risks before working on any vintage Jeep. Older parts may still contain friable asbestos, and proper personal protective equipment like an organic respirator (not a paper dust mask) and gloves should be worn. Protective clothing should be removed and washed before leaving the work area as well.

Jeep Parts Known to Contain Asbestos

Many older vehicles contain asbestos. Some of the common automotive parts made with asbestos include brake linings and pads, clutch plates, hoodliners, various gaskets and seals, and transmission parts. Jeeps certainly weren’t immune to the use of asbestos-containing parts.

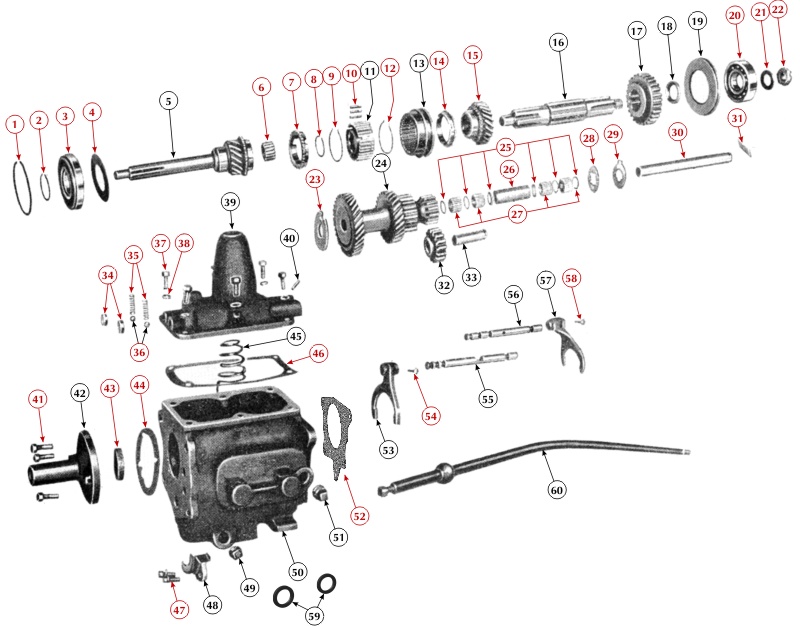

Borg-Warner Automotive, Inc., a producer of brake pads and transmission components, is the producer of Jeep transmissions and transfer cases. The company’s use of asbestos is well documented, and they face many lawsuits because of it.

Borg-Warner increased its use of asbestos in transmission components significantly during the 1960s and continued to do so through the 1980s—even as health concerns around asbestos exposure came to fruition. The automotive parts manufacturer made several manual transmissions for Jeeps. These include:

T84, 1941-45 Jeep

T86, T90, and T96, 1946-72 Jeep

T85, 1965-66 Jeep

T89, 1963-66 Jeep

T14, 1967-75 Jeep

T15, 1967-79, Jeep

T150, 1976-79 Jeep

These transmissions are highly likely to contain asbestos.

Borg-Warner continued to make transmissions for Jeeps into the 1980s, too. With the partial ban of asbestos not being enacted until 1987, caution should be taken when working on these transmissions as well, as asbestos may have still been used.

If one plans to rebuild the original Borg-Warner transmission in a classic Jeep, precautions should be taken to avoid exposure to asbestos. Although some may say that there is not enough asbestos to be harmful in these transmissions, the EPA states that no amount of asbestos exposure is considered safe. This goes for at-home mechanics as well as professional restoration technicians. Asbestos can easily get trapped on clothing and be brought into one’s home. Sadly, many family members have been diagnosed with mesothelioma due to spouse’s and parent’s occupational exposure.

Caution should also be taken when changing brake shoes and pads. Often when rebuilding a vintage Jeep for use as an overlanding or offroading vehicle, larger tires will be installed in place of smaller stock wheels. While doing so, it’s not uncommon to upgrade to larger brakes for greater stopping power. If taking off the original brakes is part of one’s restoration, it’s pertinent to remove and dispose of old brakes safely. The risk is more significant for brake drum work, as the brake dust can collect in the drum. A common way to clean out the drums is by using an air blow gun. This should be avoided, as the dust can easily be inhaled or ingested when doing so.

The Original Willys MB: Veterans and Restorers

The US military used asbestos for its heat resistance and waterproofing capabilities in numerous applications. Disproportionately, veterans make up 33 percent of mesothelioma cases today due to the heavy use of asbestos during the 1900s. One way that the military utilized asbestos was in a waterproofing compound, which was applied over the distributor and other essential parts that could not get wet. Service members applied this compound with no protective gear and bare hands—often aboard a transport vessel. This method of waterproofing allowed jeeps to stay underwater for an impressive 6 minutes at depths of 3.5 feet. However, the use of asbestos in this haphazard way was undoubtedly harmful.

This compound had to be removed immediately after being taken out of the water so that the jeep could function normally. This process was likely done as jeeps reached shore under enemy fire. The chances that every bit of the asbestos compound was removed, under the circumstances, is unlikely. The risk for restorers coming into contact with this asbestos compound today is probably little to none. If at all, it would almost certainly be jeeps that were left in Europe following the end of WWII. However, if a distributor on a 1940’s Willys MB appears to have a cakey compound on it, one should use caution to proceed.

In Closing

Restoring a vintage Jeep is an exciting project to undertake for Jeep enthusiasts. Who wouldn’t be thrilled to drive a restored classic? The restoration process, for many, is the best part of owning a vintage Jeep. One should thoroughly research the year and model to understand the risks and what parts should be treated with care. If you’re not equipped to properly handle and dispose of hazardous materials that may be on your Jeep, it might be best to leave it to the professionals for those jobs. Paying a professional and playing it safe is well worth not risking exposure to asbestos and the potential health risks. Lastly, get out and enjoy that sweet vintage Jeep!

Resources

https://www.mesothelioma.com/asbestos-exposure/what-is-asbestos/

https://www.epa.gov/asbestos/epa-actions-protect-public-exposure-asbestos