The aim was to conceive and provide the ultimate expedition vehicle in terms of performance, comfort and reliability.

The vehicle uses the latest version of the legendary Mercedes Benz/Styer Puch G 461 model, the G280 Green Line with military specification.

The Green Line model distinguishes itself from the standard G series mainly by a more rugged finish as well as its reinforced chassis and axels and by its special electrical circuitry. It has both a 24V and a 12V circuit. From this base point we added all the necessary accessories to make it the ultimate expedition vehicle.

Fitment and necessary transformation has been carried out by German based, world famous UNICAT Company specialized in development and preparation of large and unique expedition vehicles.

https://www.mercedes-g-entdecker.com/

VEHICLE SPECIFICATIONS

The lightweight and compact V6, CDI diesel engine, with 3 liters capacity, offers superb performance (183 Hp/400 Nm) with excellent consumption, and makes the vehicle capable of achieving 14 liters per 100 km. The motor also meets EURO IV fuel emission limits. The gearbox is an automatic 5-gear tiptronic as used in the latest military version, with low and high range gears. All 3 differentials are 100% electrically lockable. Vehicles are factory fitted with high performance air conditioning providing comfort in any environment.

The vehicle comes with 2 factory fitted separate electrical circuits, including 2 alternators (one with 12V and one with 24 V), and 3 batteries as well as many other heavy-duty ”military” options.

We have extended the already generous traveling range given by the standard 96 liters tank by adding 2 additional fuel tanks: one permanent tank fitted under the rear bench seat, which has a 64 liters capacity as well as a second optional tank (that can be easily mounted anytime when no rear passengers are to be taken in the vehicle) which has a 70 liters capacity. The 70 liters tank is coupled to the 64 liters tank, allowing the vehicle to carry a total of 230 liters and giving it a range of approximately 1500 km without refueling or the need of carrying separate fuel jerry cans.

Filling of these 2 tanks is achieved by electrically pumping fuel from the main tank. This eliminates the possibility of any diesel smell during filling operation (or worse, as a result of spills), which often happens when the filling of auxiliary tanks has to be done from inside the passenger compartment. Safety ball valves are fitted under the floor of the vehicle to allow drainage and recovery of fuel even in the case of a main pump failure.

A supplementary specially designed 7 or (as special option) 9 liter round jerry can has been fitted inside the spare wheel to carry spare engine oil, or emergency fuel.

The jerry can be locked to the wheel and is hidden under the spare wheel cover.

WATER TANK

The vehicle is also equipped with a specially designed polyethylene water tank with a capacity of 88 liters. The tank was manufactured out of polyethylene to ensure the quality of drinking water as well as for its lightness and ease to clean.

Furthermore a water tap for easy and convenient access to water has been fitted by the rear bumper, as well as quick coupling for connecting of a shower.

All of this is hidden by a specially designed platform, which covers the tanks and allows loading and securing of further cargo on top.

TENT WITH CARBON FIBER SHELLS

We asked Italy’s most experienced tent producer, AUTOHOME, to produce a special version of their famous Maggiolina tent, made with carbon fiber shells (powder coated in the same color as the vehicle) for reduced weight and increased robustness. The tent has 2 fully closable entry doors on each side of the car, (both fitted with separate mosquito netting) as well as 2 triangular windows in the front and rear for additional ventilation. The tent is also equipped with an internal light and is designed in such a way that sleeping bags, cushions and night clothing can be stored inside the tent even when the tent is closed for traveling. Opening and closing takes only a minute and is very simple.

CARBON FIBER LADDER

We specifically developed and produced a carbon fiber ladder, to replace the more bulky, heavy standard aluminum ladder for accessing the tent. The ladder can be dismantled into 2 sections allowing it to be easily stored inside the tent. Steps are oval and with special rough finish to allow easy and comfortable, use even barefoot without danger of slipping .

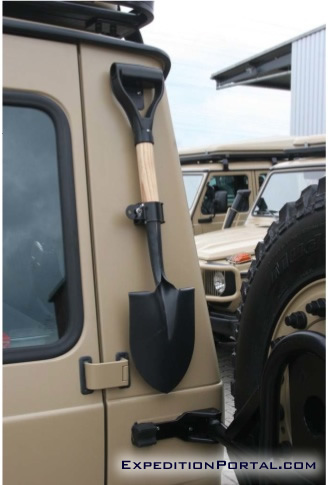

TITANIUM SPADE WITH CARBON FIBER HANDLE

We have had a special titanium shovel head made and fitted it with a carbon fiber handle. There is no lighter functional spade available.

One additional spade has been conveniently placed behind spare wheel.

DOUBLE REAR DOORS

The vehicles have been ordered with 2 rear doors, to ease access and allow opening of the left door without having to disengage the spare wheel carrier. The draw storage unit is also split to allow the left-hand draw to open with just the left side door open.

FRONT-RUNNER CUSTOM MADE ROOF RACK

The South African specialist for “african terrain proof” roof carriers and 4×4 equipment, FRONT RUNNER, have produced a special model of roof carrier specific for this vehicle and for the Maggiolina tent. It is made entirely of welded and bent aluminum extrusions that are powder-coated to achieve a stylish and long lasting finish. Once again, every effort has been made to achieve a robust product with light weight, that is aesthetically pleasing.

HI LIFT JACK

A hi-lift jack is neatly fitted to the side or as an option with different special custom made brackets to the rear of the roof carrier for easy, convenient access.

Hi-lift Jack lifting lugs have also been fitted to the vehicle to provide safe and efficient jack usage.

AIR INTAKE WITH SNORKEL

The air intake has been fitted with an original Mercedes-Benz snorkel (developed specifically for this G model) to allow deeper wading when crossing rivers and to supply less dusty air (due to its height) to the engine providing better efficiency and longer engine component life.

ALUMINUM SPLIT RIMS WITH BEAD LOCKS

We have equipped the vehicles with special split rims fitted with beadlocks. These allow removing and replacing of the tire in the event of a puncture without have to remove the actual rim from the vehicle. Even more important, the beadlock allows reducing of pressure inside the tires to values as low as 0,5 bars without the risk of the tires slipping off the rim. This provides major traction advantages when driving in deep sand or snow.

ON BOARD TIRE PRESSURE ADJUSTMENT

Each vehicle is fitted with 2 separate air compressors and an air tank to secure pressurized air at all times. We have chosen to fit 2 smaller compressors (rather than one large model) to ensure that there is still the ability to pump air even in the case of failure of one compressors. These are coupled to a special pressure regulator that allows all four tires’ pressures to be simultaneously adjusted (increased or decreased) in minutes. This can be achieved by simply connecting specially designed tire connection hoses to quick couplings which are placed next tothe rear doors on each side of the vehicle.

There is also an air nozzle gun that can be connected to the air tank, which is very useful for cleaning dust etc away in and around the vehicle.

Tire air pressure and temperature monitor is also part of the fitted equipment.

INTERIOR

Interior is basic but robust- windows are manually operated, with controls for only the most important features. There is however, the much needed map reading light.

There are both 24V as well as 12 V plugs that are factory fitted on the dashboard. The vehicles are also factory fitted with battery isolator switches on the console that operates both the 12V and the 24V circuits.

As an optional extra we can fit a supplementary POD that is fitted on top of the dashboard, which offers additional space for extra controls or devices (in the picture IPHONE cradle, 2 way radio and Garmin GPS). The POD can incorporate all the necessary transformers and cables for these supplementary devices within it, resulting in a neater centre console.

The plastic shell of the POD can be easily and cheaply replaced with a new one should different (newer or alternative) or additional accessories need to be installed. There is also room to fit a satellite phone with headset. An on board fanless computer with roof mounted touch screen and built in navigation and GPS has been fitted as well.

NATIONAL LUNA REFRIGERATOR/FREEZER

We have equipped each vehicle with 2 separate stainless steel fridge-freezer units. These are connected to operate from the 24 V circuit. Connection is through rugged military metal plugs and sockets with a special water tight sealing cap that allows to seal off and protect socket when not in use.

This keeps these accessories off the engine’s circuitry providing unparalleled reliability. We chose NATIONAL LUNA as they boast superior cooling power and exceptional efficiency even in the harshest environments.

Each of the 2 units can be set anytime to work at positive (refrigerator) or negative (freezer) temperatures, to suit specific needs. We have designed a special platform to fit over the permanent auxiliary tank that takes these 2 units when there are no rear passengers. This also allows easy access of these appliances from driver and co-driver seats. When more people are travelling and the rear bench is fitted, the units can be moved to the trunk/rear part of the vehicle. There is sufficient unused empty space in front of the fridge to store and secure travelling luggage and other objects.

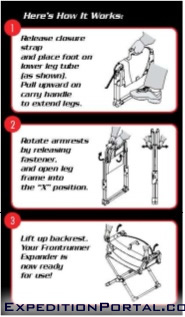

CAMPING CHAIRS

We have tried to find a chair that is comfortable and robust and gets small enough, once folded, to be easily stored. Eventually we have found the perfect one, which very recently became available, that easily fits inside the draw system we have designed for the vehicle. It can even be stored in the aluminum boxes that fit on top of the draw system.

The chairs can carry people that weigh up to 115 kg and once folded only occupy 43 x 5 x 40 cm of space!

We are equipping each vehicle with 4 of these chairs, 2 with armrests for normal use and another 2 (even more compact ones) without armrests for guests.

DRAW SYSTEM

Vehicles have been fitted with a double draw system. These heavy duty draws run on double ball sliders providing the smoothest action even under the heaviest loads. The left draw is accessible from the outside of the vehicle by opening just the left half of the rear door, thus

providing easy access to the frequently used accessories. The draw system is locked by compression latches, preventing any rattles, to the back shelf which has a non slip deck surrounded by countersunk aluminum airlines anodized in black.

This allows the customer to select any one of numerous types of storage boxes as well as providing infinite options for securing any load.

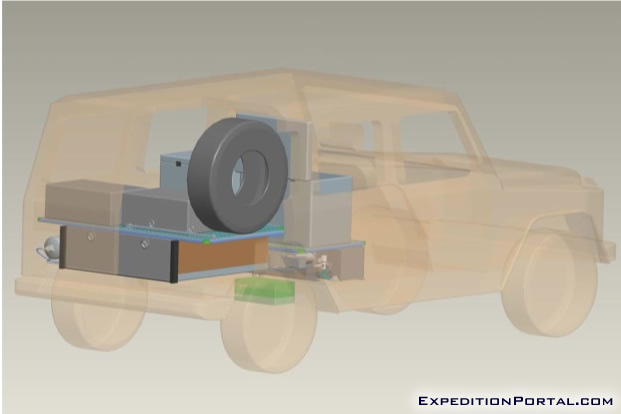

CAD DESIGN

In order to deliver the ultimate expedition vehicle, there was only one way to do it- by using Computer Aided Design (CAD). This allowed us to optimize space utilization and provide a first time fit for all the accessories.

Check out the Mercedes Geländewagen in the Summer 2011 issue of Overland Journal, or read the article and watch the video here. [link]

For inquiries contact :

DIMES

SAVia Zurigo

356900 Lugano

Switzerland

Phone +41 91 923 37 61

Fax +41 91 923 98 86

Email: dimes@ticino.com

or

UNICAT

Gmbh

Gewerbering 7-21

76706 Dettenheim

Germany

Phone: +49 (0) 7255-7606-0

Fax: +49 (0) 7255-7606-16

Email: info@unicat.net

Internet: www.unicat.net