Titanpat57

Expedition Leader

Hi All,

The new build is under way and I have a question.....

I stripped off the landing leg and surge brake on the M116A2(anybody that wants it welcome to come get it before I chuck it) and the plan is to add 3"x 1-1/2" box steel under it, some 3" sqaure tube and a standard 2" coupler.

Now the problem....

Should I incorporate in the new tongue design for the Max Coupler? My off roading will be minimal, and really the cost is immaterial....I just don't want to kick myself in the ***** two years down the road.

Does a standard coupler have that little articulation that it won't do well in some rough terrain? I know there was some issues in the past with some brand bending, although I don't remember which one.

All thoughts are welcome, thank you in advance.

Pat

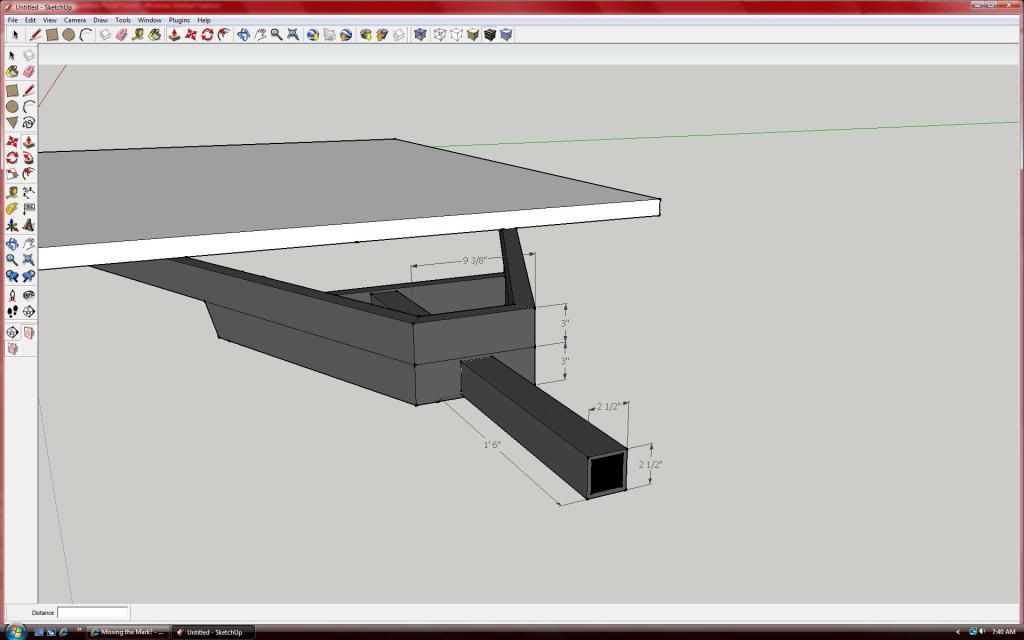

Ive included a pic to show the starting point.

The new build is under way and I have a question.....

I stripped off the landing leg and surge brake on the M116A2(anybody that wants it welcome to come get it before I chuck it) and the plan is to add 3"x 1-1/2" box steel under it, some 3" sqaure tube and a standard 2" coupler.

Now the problem....

Should I incorporate in the new tongue design for the Max Coupler? My off roading will be minimal, and really the cost is immaterial....I just don't want to kick myself in the ***** two years down the road.

Does a standard coupler have that little articulation that it won't do well in some rough terrain? I know there was some issues in the past with some brand bending, although I don't remember which one.

All thoughts are welcome, thank you in advance.

Pat

Ive included a pic to show the starting point.