I was curious about exactly how the Harbor Freight solar controller works so yesterday I used an oscilloscope to look at the output waveform. I know the HF unit is a PWM (pulse width modulation) controller but I wanted to see exactly what the output voltage is and how the output is modulated.

If you're not familiar with PWM, here's a Wikipedia article about it:

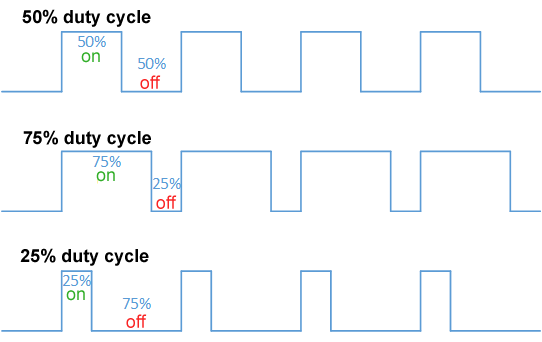

https://en.wikipedia.org/wiki/Pulse-width_modulation. Simply put, PWM varies the power by outputing voltage as a series of pulses. The "duty cycle" (on vs. off time of the pulses) determines how much total power is output over time. This image is from the Wikipedia article and illustrates duty cycle (By Thewrightstuff - Own work, CC BY-SA 4.0,

https://commons.wikimedia.org/w/index.php?curid=72876123):

I was interested in seeing several things about the solar controller:

- The maximum amplitude (voltage) of the pulses

- The duty cycle when the battery is charged, discharged, and under load.

I used a small handheld digital 'scope for these measurements. Here's my setup for this test, left to right: HF Charge Controller, solar panel output volt + amp meters, handheld 'scope, voltmeter (for verifying voltages) and of course the kitchen power panel (offscreen to the left) and the fridge (below).

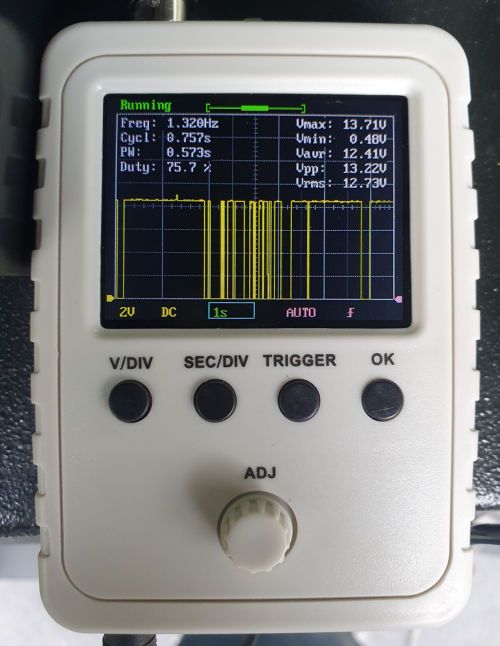

In this next image, the fridge has just been started and the battery is fully charged:

The settings on the 'scope are 2 volts/division vertically so visually it's a bit over 13 volts, and the numeric display at the top of the screen confirms that. Max voltage is indicated at 13.71 volts, which is high enough to charge the battery, given enough duty cycle.

Horizontal divisions are 1 second and the numeric display indicates the frequency is about 1.3 hz, although as you can see from the waveform this varies quite a bit. I was expecting a more regular frequency, so this somewhat random frequency was a bit of a surprise.

Duty cycle is indicated at about 75%, which means 75% of the time the controller is supplying power to the kitchen and 25% of the time it is not.

The ammeter monitoring the solar panel output was indicating slightly less than 2 amps when the waveform photo above was taken, and the kitchen draw as measured by the ammeter on the kitchen power panel was just over 5 amps. With the duty cycle of the power out of the solar controller being 75%, the solar panel is picking up some of the kitchen load.

I'll do more testing but this is just for intellectual curiosity and educational purposes. I like to understand how things work.

.jpg)