“An overland vehicle is not perfect when you have added the last possible modification, but when you have taken the last possible modification away. ” –our adaptation of Antoine de Saint-Exupery’s famous quote

After a few trips around the world and crossing all seven continents, these are the lessons we have learned (mostly the hard way) about properly modifying your overlanding vehicle for adventure travel.

Editor’s Note: This article was updated on September 23, 2019.

1) Complexity is the Enemy: Keep the vehicle as simple and reliable as possible, minimizing the number of systems and variables that can fail in the field. Adapt only as required for the vehicle to perform in the environments and conditions expected in your route. Consider the engineering performed by the OEM manufacturer, and how all of the factory systems interrelate. The vast majority of failures we see to 4WDs are aftermarket modifications, and of those, electrical and engine system modifications are the most prone to failure.

Reliable, robust vehicles with minimal modifications rule the day and will exceed expectations in nearly all conditions when combined with driver training and experience.

2) Weight is Also the Enemy Keep the vehicle as light as possible, removing heavy items that provide limited value, are purely aesthetic, or are never used. The goal should be to stay under 90 percent of GVWR, which will ensure the best performance in technical terrain, particularly snow and sand. “Stuff” is always a reflection of experience and training. The more experienced, well-traveled, and well-trained the traveler, the less stuff they carry, and the fewer modifications they need.

Nearly everything I have learned about minimalist overlanding has come from travel on a motorcycle. All of the gear I needed for months on the road fit in a few bags, less space than needed in the passenger seat of a traditional 4WD. Less is more.

3) Suspension Performance The suspension system, geometry, and handling with a load are a reflection of proper design. The vehicle must perform just as well on pavement as it does on the dirt. A suspension serves several critical roles, including emergency handling (think avoiding a deer or child that runs into the road), load carrying, and technical terrain performance. Who cares if you can achieve a 1000 in the ramp travel index if the truck rolls at speed on a dirt road. The suspension should also be robust, with quality shocks and durable components. Properly configured, a modern vehicle should be able to manage technical obstacles and also exhibit predictable and safe handling during high-speed dynamic inputs. Remember to tune the suspension to your travel load, including the spring rates and lengths, along with compression and rebound valving. This video shows what is possible with a lifted overland vehicle on 35-inch tires, fitted with a proper suspension.

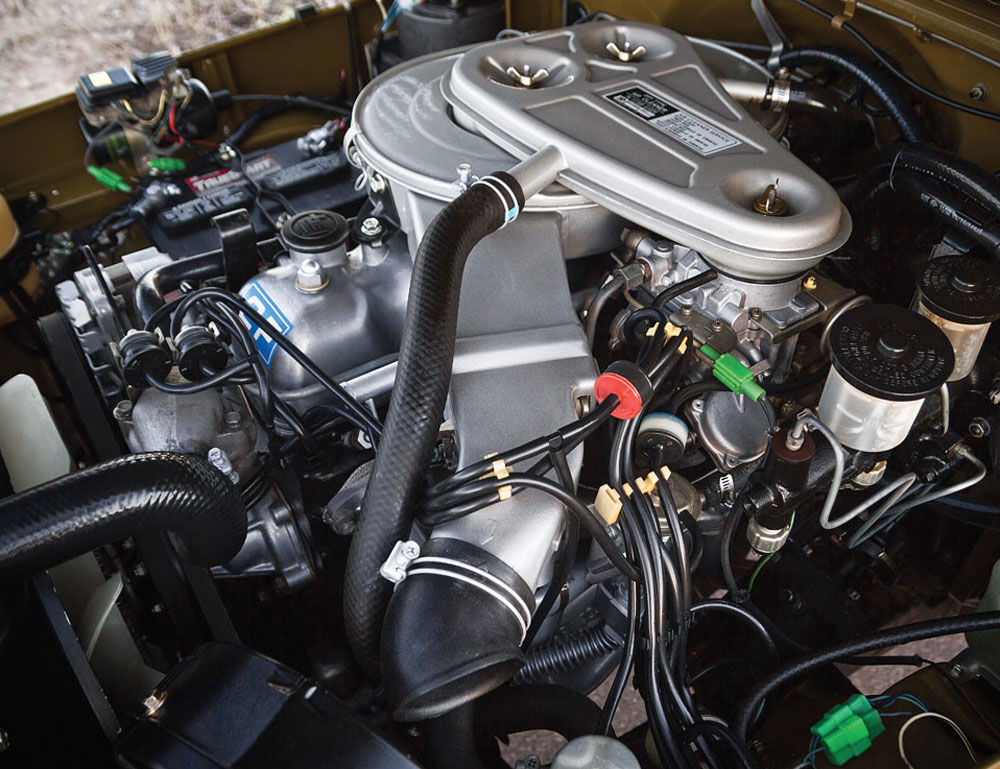

4) Keep the Engine Stock This is the most common mistake we see with vehicle preparation: dozens of little modifications to the engine, including changes to the ECU, headers, cold air intakes, aftermarket turbochargers, etc. These all seem like a great idea until you need to repair one of those items in the middle of the Gobi Desert or find a replacement belt in Uganda. Certainly, there are proven or even mandatory upgrades that address known failure modes of the factory components, but otherwise, leave the engine mods to the tuner crowd. If the environment you are traveling in demands a certain amount of power (like sand) then buy the right truck with the right engine to start with.

5) Isolate and Minimize All Electrical Modifications Electronics are the bane of all travelers, taking more time and requiring more “fiddling” than any other system. The reality is that most modern overlanders do use and often need electronics to enhance their experience, including digital cameras, GPS units, and tablets to navigate by and record their journey. However, miles of wiring, fuses, and connections are some of the most common failures. As a result, completely isolate all “house” electrical systems from the factory harness and use a dual-battery system and auxiliary battery to protect starting voltage. Spend the time or money necessary to ensure the wiring is 100 percent correct, including quality components, weather-tight connections, and proper fusing. Electronic gadgets are so appealing that they often waste volumes of time and create major distractions to the driver.

6) Use High-Quality Tires with an Appropriate Tread Pattern Tires are the most common failure item on a vehicle as they are always in contact with the terrain. Install a high-quality radial tire (for standard vehicles) in a conservative tread pattern for the terrain you are intending to travel. While the mud-terrain tire might look the part for your trips in the Desert Southwest, it is far from necessary and actually hinders performance. The tread should always match the intended use as should the tire size. There is nothing wrong with a huge tire if the conditions demand it, but the vehicle should still perform appropriately on the road. I needed 44-inch tires to cross Antarctica but only required a mild 30-inch all-terrain tire to drive the Silk Road. Buy a tire with a load rating above your GVWR and look for manufacturers with heavy-duty sidewall construction. Note: The mileage warranty is not necessarily an indicator of tire quality, as long warranties require a harder durometer compound to ensure long life. This often impacts adhesion, wet weather traction, and braking distances negatively.

While a mild all-terrain tire may not satisfy the aggressive look many people want, they work exceptionally well for overland travel in mixed terrain and all desert environments. As a driver, there is the added benefit of increased fuel economy and lower driver fatigue. For our project G-Wagon, we have been testing the Continental TerrainContact with good results.

7) Avoid Roof Loads This is the most common mistake of the new overlander: packing everything and the kitchen sink on the roof. There is nothing wrong with a lightweight roof rack, but having a roof tent, spare tire, and six jerry cans is extremely dangerous. Even a basic understanding of physics will prove why that is such a terrible idea, and those types of loads create a litany of problems, including dangerous handling due to the raised center of gravity (COG), poor technical terrain performance, reduced fuel economy, and potential roof damage. Loads must be as low as possible and as close to the centerline of the vehicle (fore/aft) as possible. If all that gear needs to be on the roof, you probably bought the wrong vehicle. For most vehicles, the maximum roof load should be less than 120 pounds—I prefer less than 70, or ideally, a completely empty roof rack.

During Expeditions 7, we took the same Land Cruiser to all seven continents, and we never needed a permanent roof load. We packed minimally and slept inside the vehicles or in ground tents.

8) Self-Recovery Often overlooked, proper training and equipment for self-recovery are critical. So much attention is paid to lockers and suspension that self-recovery is usually an afterthought. In reality, self-recovery equipment and the skills to use it are more important than any other modification and should be the first consideration when leaving the beaten path. The reason for this is simple: everyone gets stuck, even with the best possible vehicle and most experienced driver. There will always be mud too deep, or a rock too large, or sand too soft. A winch can provide control and mechanical advantage that no 4WD modification can match. If your route includes remote, off-highway (off-road) travel, then consider a high-quality winch rated to 1.5 times GVWR, a ground anchor, comprehensive recovery kit with pulleys, line extensions, and related connections. We have also found traction plates/mats/boards to be essential for extreme bog conditions, and we now carry at least four. Mounting a winch often includes a quality bumper, which can also serve to protect the vehicle from an animal strike, low-speed accident, etc.

Our recovery kit evolved over time through trial and error, including a 14-hour stuck along the Canning Stock Route in Australia. Now we never leave home without a set of traction boards.

9) Secure the Load Take the time to secure all loose items in the cab, ensuring that proper lashing points are installed throughout the vehicle. This includes securing all soft luggage and in particular, all hard/heavy items. Even a big bump or ledge on the trail can cause items to shift forward in the cab, impacting passengers, or worse, the driver as they are attempting to clear an obstacle. In the case of a roll-over, those items can kill or seriously injure occupants. Install load mats and ratchet straps to keep items from sliding and bouncing. Watch items that can roll forward along the floor into the driver’s footwell and secure small items with a properly sized center console. Drawer systems can be quite convenient and also improve loading and lashing, but be careful with their weight.

This Jeep J8 military-spec Wrangler is designed for a full metric ton of payload. We kept it at stock height and only added a winch and rack from the stock specification. It served for years as our training platform with the US Special Forces.

10) Quality and Design Over Quantity Contrary to what we see on the web, it is not the truck that defines you, but your experiences. Experiences can be enhanced by thoughtful design and a quality product, but also easily end a trip with a broken aftermarket spring that saved you a few dollars over the proven brand. If price is a factor, then just leave the vehicle stock. We are far better off modifying our vehicle with slow and deliberate purpose than just checking off the list of things we think we “need.” A stock, properly maintained Land Cruiser can easily drive around the world and take on some seriously remote and rugged terrain along the way. So, make modifications only as absolutely necessary, and save all that money for gas, a good camera, and that 20-foot container shipment to Cape Town.

The Entdecker G-Wagen is one of the most exceptional vehicle builds ever produced, a partnership between Unicat and Front Runner using the G-Class Professional model. The roof tent is carbon fiber and the rack aluminum, keeping the roof load below factory limits. The vehicle is stock height and uses modest tires. We have driven this SUV in several African countries, including Kenya and Uganda, and never suffered a failure with the modifications.

Simplicity and reliability is the key to vehicle preparation for long-distance adventure travel.

A final thought to consider: I am often asked how much money someone should spend on modifying their vehicle. My answer is always “the least amount possible.” In fact, we should invest far more money in the actual experience of travel than we ever do on the vehicle. There are fake beadlock wheels that cost more than a few weeks in Baja. Stick with the stock wheels and go get some tacos on the beach (grin).

This feature first appeared on Expedition Portal in January of 2014. We have updated the content and images to better serve the reader in 2019.

We have learned many of these lessons the hard way, including one of our first project vehicles, a 2004 Toyota Tacoma, which was so overloaded and complex that it resulted in constant issues and repairs. As we gained experience, the modifications slowly reduced to our current mantra.

5 Comments

Kyle

August 1st, 2018 at 12:49 pmI agree, trying to keep the engine stock is important, but can also be the cause of further isssue. My 1990 Lada Niva is awesome but the engine isn’t it breaks constantly, since bodging a Mitsubishi turbo diesel into it, it’s a new car; responsive, enough torque to pull a house down and most importantly it’s reliable 70,000 miles later I haven’t had to touch it aside from basic servicing. Whereas my Ford Ranger Honesberie (the third most powerful pickup going) is very nice but lacking high end power so I felt it essential to remap it, fit a powerflow 3” exhaust and a bigger turbo with a meaty intercooler. I don’t feel the Fords reliability has been hindered because of the quality of parts and craftsmanship.

On the topic of self recovery I don’t like going to my cars with a hammer, grinder and hacksaw, so I keep it simple with 2 Maxtrax and a ratcheting hoist I can keep in the back it weighs less than a 12 pack and and pulls 7000lbs like it’s not there.

Regards Kyle

Jay

October 13th, 2018 at 6:48 amThey covered this when they stated, “Certainly, there are proven or even mandatory upgrades that address known failure modes of the factory components, but otherwise, leave the engine mods to the tuner crowd.”

There are a few things I disagree with however. Talking about weight is the enemy, they mention snow. Out here in Wyoming, USA, we have snow and ice covering 80 mph highways with 40-50 mph crosswinds pretty much all winter. You have to cross ’em if you want to get anywhere and there’s hundreds of miles of open desert around you. You want some weight if indeed the vehicle should ride well on the road- unless you want your vehicle to turn into a Wizard of Oz house.

Another thing is they say, “If the environment you are traveling in demands a certain amount of power (like sand) then buy the right truck, with the right engine to start with”, whereas 90 percent of overlanders say to ‘start with the vehicle you have’. Not all of us can drop 30k on a purpose-built vehicle. Its a contradictory statement compared to the general train of thought.

Lastly, this statement, “The amount of lift is less relevant than how it performs. There are vehicles with no lift that are easily outpaced by a proper suspension with four inches of lift. Remember to tune the suspension with your travel load.”, is inside-out. It is stating lift is not relevant, then speaks of how 4″ lifted rides outpace stock heighters. Hmmm…

Scott Brady

October 13th, 2018 at 11:47 amJay,

Vehicle weight is not relevant with ice/snow covered roads. Weight distribution can influence handling and traction, but overall vehicle weight is not a factor.

Regarding buying the right truck, that is simple a fact. If someone’s financial situation is a limitation, then that is simply a compromise that their finances demand. People make the mistake of defending a compromise. There is nothing wrong with a compromise if the person is honest about it…

Suspension performance is the most important attribute. The comment on a 4″ lift is incidental. If the conditions or desired route demands more ground clearance, then that is the reason to add lift. Lifts are often added as a bandaid to limited driver skill.

Pingback:

November 27th, 2018 at 5:58 pmPingback:

January 16th, 2020 at 7:10 pm