I saw this when it was posted, but am just now getting a chance to respond.

Disclaimer: "I am no expert on this, except for I have worked for years around certified welders and welding inspectors, and have also welded my own projects for years."

The explanation of the heat affected zone (HAZ) given in post #8 could have been more detailed. A better explanation can be found here:

https://app.aws.org/forum/topic_show.pl?tid=125

The reference also gives information on how to minimize the HAZ, including the use of preheating. If you are fabricating your project in the wintertime in a cold space, I suggest that you always preheat.

If you have seen a tensile strength test on a weld, you will notice that on a good weld, the failure always occurs in the HAZ.

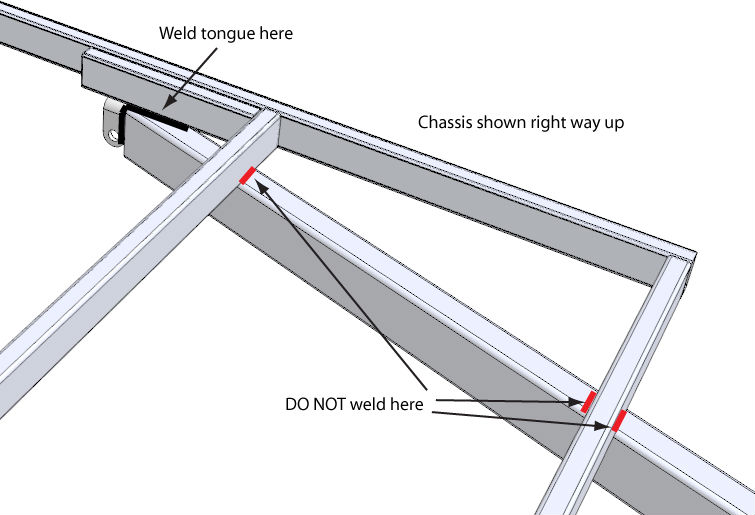

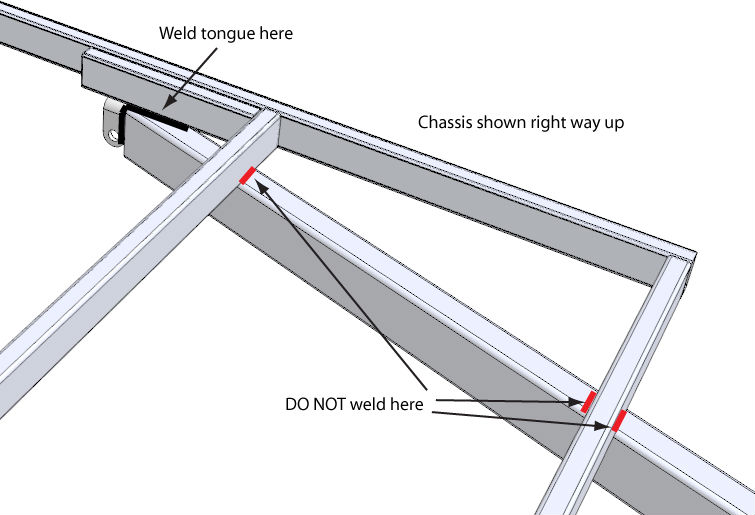

Especially the tops and bottoms of the tongue and the main frame rails are subject to tension and/or compression, and can alternate between the two.

Placing a weld anywhere creates a HAZ on each side, parallel to the weld, as well as creates stresses in the weld and base metal, so there is a lot more going on here that one would expect.

If you want some information on the how critical welding on a frame can be, google welding procedures on truck frames. You will find welding forums on this subject, and you will find welding procedures from the truck manufacturer's engineers as well. Generally all welding is prohibited by frame manufacturers on the top or bottom flanges. Granted there is the potential for much greater liability from an improper welding procedure on a commercial truck frame, but the principals of the frame loading are the same as on our much smaller trailers.

Another potential for cracking that I have frequently observed is the crater at the end of a weld string. You should pause at the end for 2-3 seconds and allow this to fill in.

A lot of our smaller trailers manufactured by smaller companies who have no engineering staff, and who do not employ certified welders, so they are not aware of these issues. And usually there are no issues, but usually when someone learns the correct way to perform a task, they will stick with it.

Welding is much more technical than most of us realize. As far as I know, Ohio State University has the only ABET accredited welding program in the US. Starting pay for these graduates is equal to a chemical engineering graduate with 100% placement pretty much guaranteed after graduation.

Personally, I do not weld in these areas and will use automotive seam sealer in an attempt to keep out water and rust.

The welding industry has a saying: "sometimes the best weld is no weld."

If you are serious about welding, I suggest attending some classes at the local vo-tech. Many of them have good relationships with the AWS and excellent instructors.