john lovett

Observer

Hi pods8,

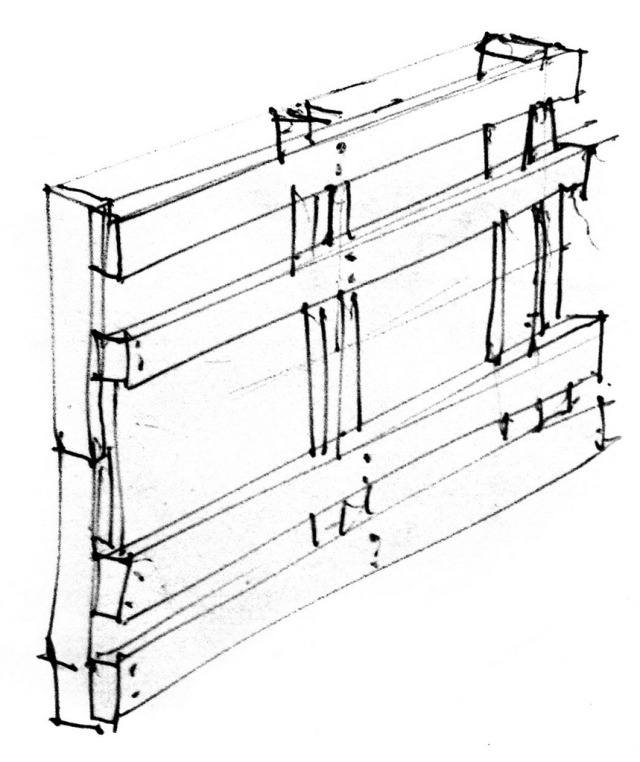

Most of the strength comes from the ply laminate - the glass is to seal the structure and strengthen the joints hence the stitched reinforcement. On the original caravan I used west system epoxy - good but expensive and smells like hell. The Vinyl esther is cheaper and not as strong smelling as the epoxy. I believe the epoxy penetrates better, so the ply was first soaked in vinyl esther, then as soon as it went off, re soaked, cloth applied then wet out. The stitched stuff took a lot of wetting out and would only curve around fairly large radius. Awkward to use, but once in place seems very strong.

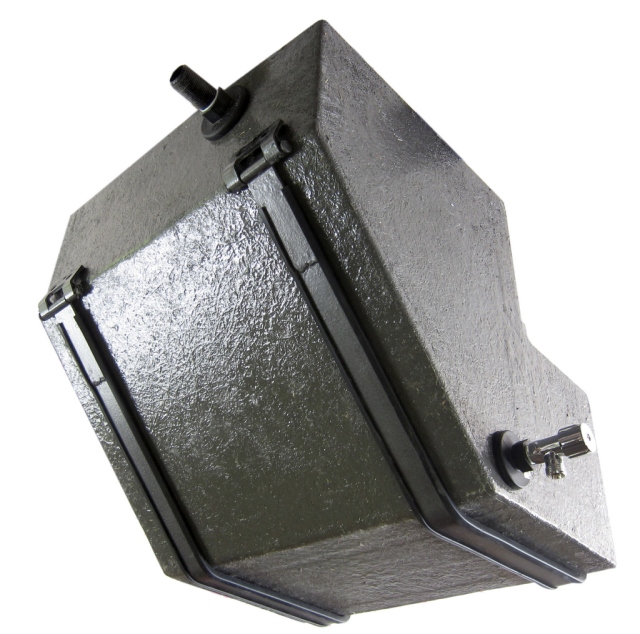

Another reason FGI, the fiberglass supplier, recommended vinyl esther was because it is much more tolerant to heat than epoxy, and the subframe sits above a large muffler!

Most of the strength comes from the ply laminate - the glass is to seal the structure and strengthen the joints hence the stitched reinforcement. On the original caravan I used west system epoxy - good but expensive and smells like hell. The Vinyl esther is cheaper and not as strong smelling as the epoxy. I believe the epoxy penetrates better, so the ply was first soaked in vinyl esther, then as soon as it went off, re soaked, cloth applied then wet out. The stitched stuff took a lot of wetting out and would only curve around fairly large radius. Awkward to use, but once in place seems very strong.

Another reason FGI, the fiberglass supplier, recommended vinyl esther was because it is much more tolerant to heat than epoxy, and the subframe sits above a large muffler!