Britboaters

Observer

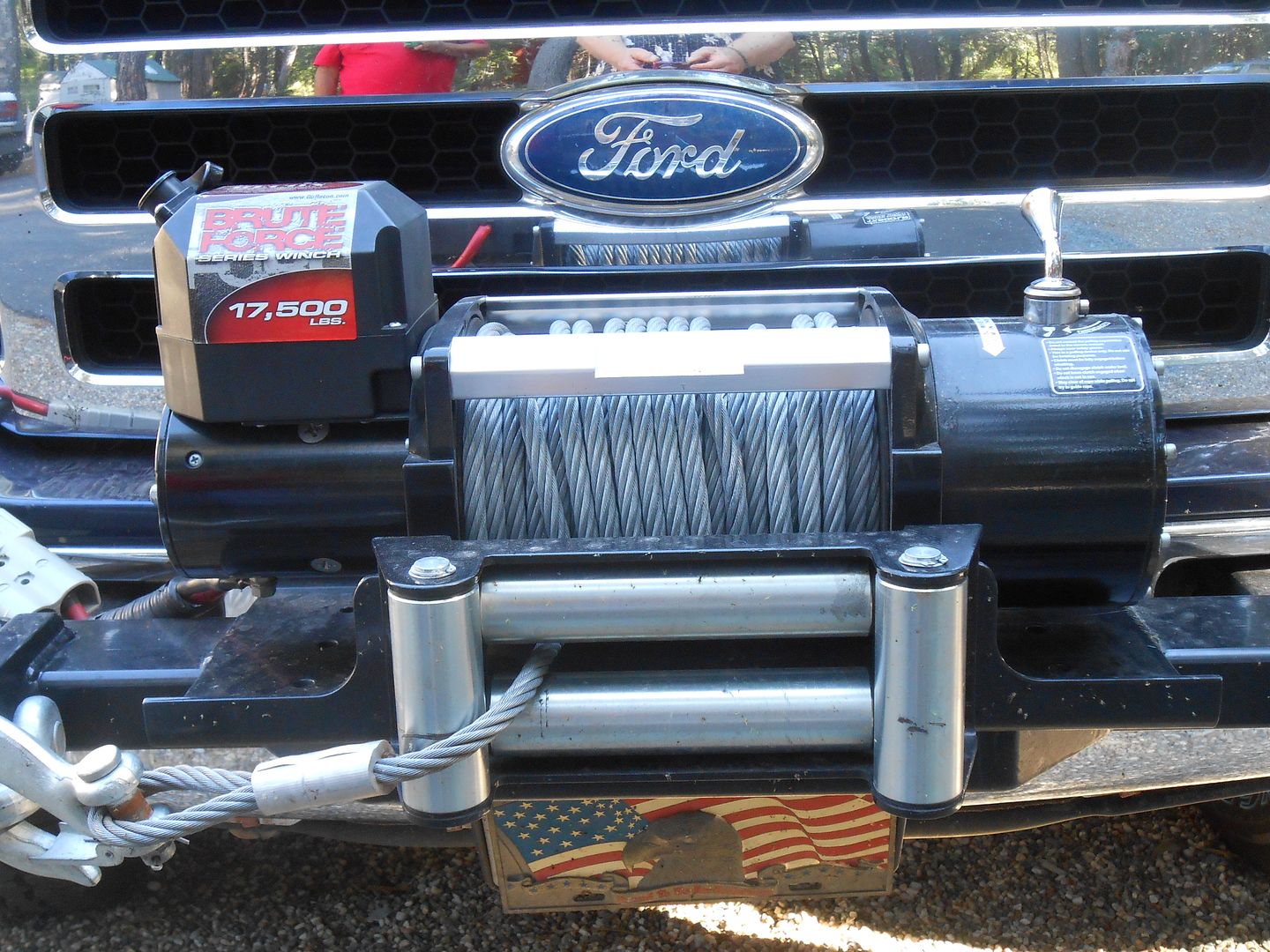

I'm building a camper based on a GMC Topkick 4WD truck. Max weight should be in the order of 16,000 lbs. So conventional wisdom say I need a 25,000 lb winch !

So I bought a Sherpa 25k winch, with Dyneema rope. The winch is surprisingly light, at about 65 lbs.

This got me thinking I could mount it in a receiver hitch, both back and front - to either get me out of trouble, or further in !!

The 2.5", class V receiver hitches I've seen have generally been rated for 15,000 lbs towing capacity. This is designed for all the dynamic loading associated with trailer towing.

The hitch on the back of my truck is welded to a piece of 8" x 4" box, bolted directly to the frame with 8 - 1/2" grade 8 bolts; so I feel pretty confident in its strength. I can fab something similar for the front.

My rational is that the the crossmember will be about the same strength whether I mount the winch directly to it, or whether I weld in a receiver hitch. The actual winch mount that goes in the receiver can also be very stout. My concern is the 5/8" pin that holds the mount in the hitch. I've never seen any specs on capacity, or the steel used for these pins.

I can of course open up the holes and use a larger pin, maybe 3/4, or 1" based on the load calculation, steel specs and safety factor.

So what are your thoughts / experience on the real capacity of this setup please ?

Thanks

Bob

So I bought a Sherpa 25k winch, with Dyneema rope. The winch is surprisingly light, at about 65 lbs.

This got me thinking I could mount it in a receiver hitch, both back and front - to either get me out of trouble, or further in !!

The 2.5", class V receiver hitches I've seen have generally been rated for 15,000 lbs towing capacity. This is designed for all the dynamic loading associated with trailer towing.

The hitch on the back of my truck is welded to a piece of 8" x 4" box, bolted directly to the frame with 8 - 1/2" grade 8 bolts; so I feel pretty confident in its strength. I can fab something similar for the front.

My rational is that the the crossmember will be about the same strength whether I mount the winch directly to it, or whether I weld in a receiver hitch. The actual winch mount that goes in the receiver can also be very stout. My concern is the 5/8" pin that holds the mount in the hitch. I've never seen any specs on capacity, or the steel used for these pins.

I can of course open up the holes and use a larger pin, maybe 3/4, or 1" based on the load calculation, steel specs and safety factor.

So what are your thoughts / experience on the real capacity of this setup please ?

Thanks

Bob

Last edited: