Rear install done.

Not much to report on the install.

Pinion preload was a bit of trail and error. I think it took about 5 tries to get it right. I ended up with just about 6-8 inch pounds rolling. That is suppose to be good for used bearings. That actually felt a little tight but I will roll with it. I installed the new yoke and new pinion seal. I didn't forget to install the pinion seal splash guard baffle thing.

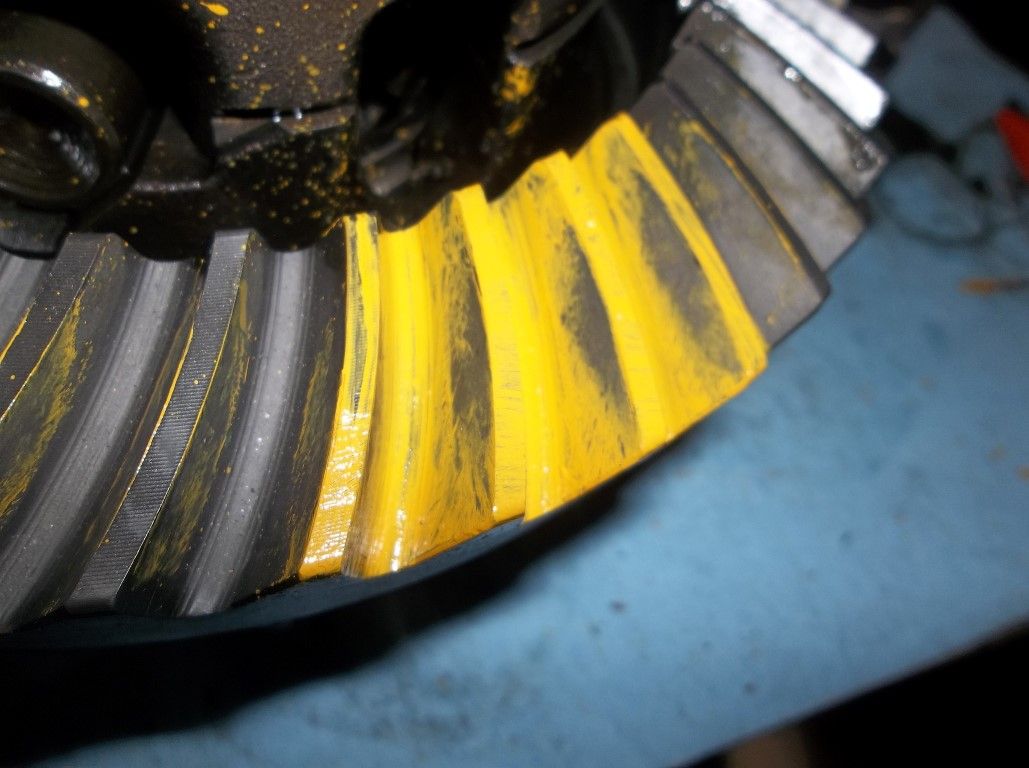

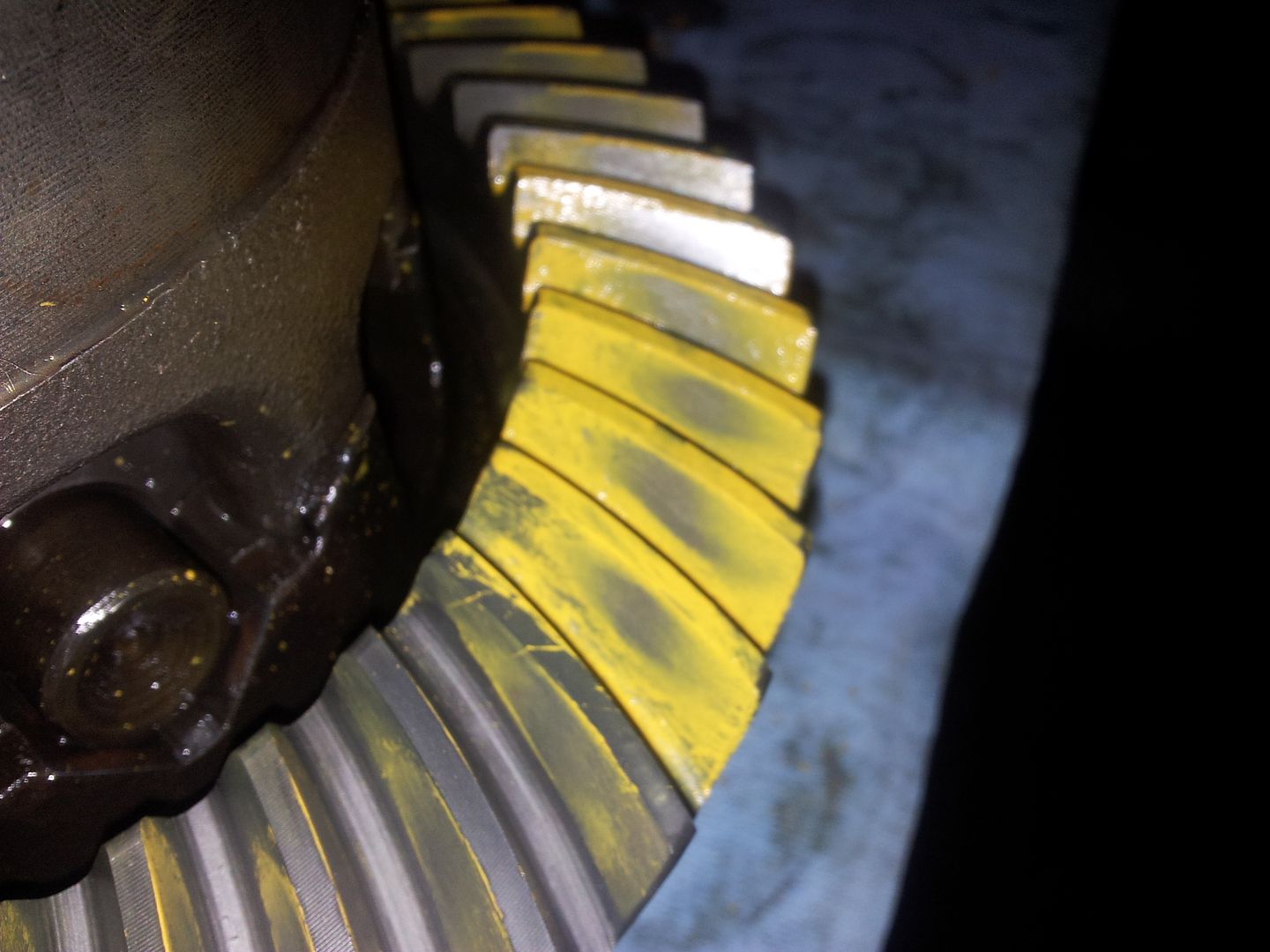

I kept the pattern the same but added a .005 shim on the right of the carrier and a .004 on the left side of the carrier for preload. That gave me a total of .012 of preload. It shifted the backlash EVER so slightly. I gained about .001 on backlash I think. My backlash average was .006-.007 and I couldn't find a low or high tooth beyond that.

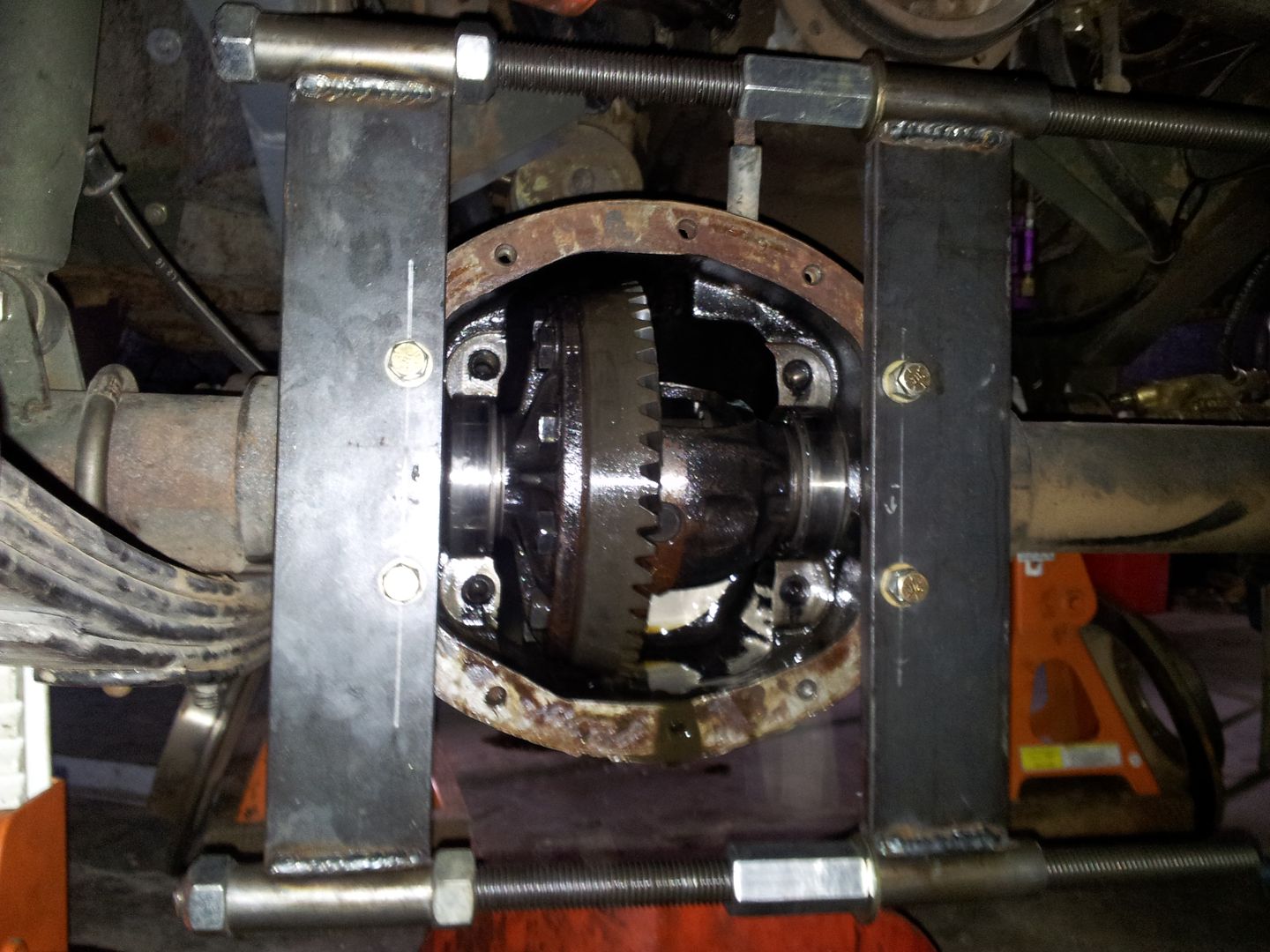

Preload in the case was pretty easy with the spreader. It still took a few wacks with the deadblow to get it in. I think if you would have had the axle on the table it would have went in.

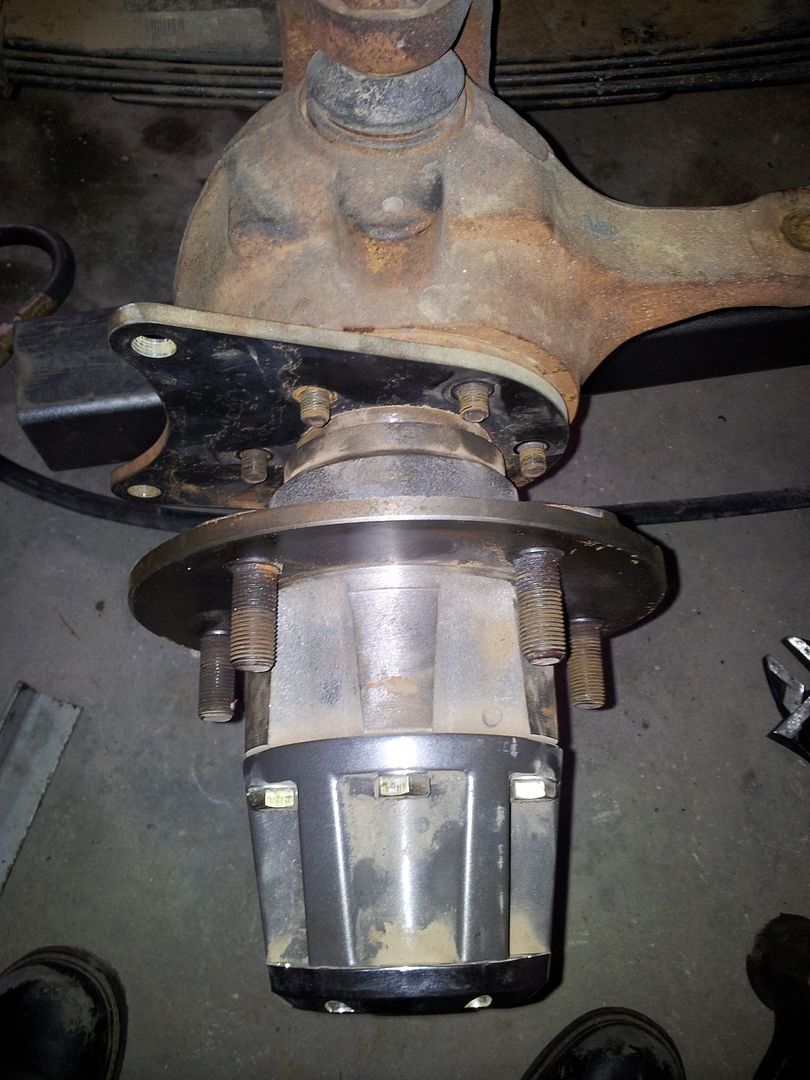

I got everything bolted up. Found a slightly loose wheel bearing on the passenger side rear. Fixed that really quick.

First drive.

It's lower that is for sure!

It feels a little more peppy overall. Once you get into 3rd gear you can pretty much run it down to 600rpm and it will pull back up without much issue. I think you can almost start in 3rd. I like my clutch so I don't really need to do that. If your rolling you can be in 3rd though you don't need 2nd for driving around town, maybe parking. 1st gear high kinda feels like low range. I think I could do some pretty decent wheeling in high range for sure.

4th gear is MUCH nicer than before, I can really use it now. You can go down to 1500 in 4th and still pull up from it. 2000rpm is about 40 I think and the engine seems very happy pulling that. 2500-2600 is a sweet spot in 4th for sure. That should be 50mph. I didn't get to cruise any faster than that yet. I need to go down to the highway. It cruises at 45-50 completely off the power valve.. Air fuel is happy in the 13.5-14 range. Get on it and the power valve kicks in and you go to 12:1 or a little richer. I was trying not to hot rod the fresh gears.

If the weather holds I am going to drive it this weekend and try and get some good heat cycles on the new rear gears.

I fooled around in low range 2wd a bit. It feels pretty dang low!

1st low feels really low. No stopping it with the brakes. I am sure in 4wd it will be different, but the front tires lock up and the rear tires keep trying to push. I need to see what happens on pavement

It seems to crawl pretty dang slow. Its only 83:1 but with 35s and the buick chugging along that feels pretty slow. It will be interesting to see how it does in the deep snow. The motor seems pretty happy to chug so I may be able to lower the idle significantly. I need to make a little hand idle control or something.....

2nd low feels like a very usefull low range gear. It will idle along in 2nd no problem up the driveway. It doesn't really even pull the idle down.

3rd low. It will idle along in that gear too. Chug chug chug.

4th low. The transfer case starts to whine a bit at those speeds.

Overall I am VERY happy with the 5.38s so far. I am sure I will wish for something a little different at certain times, but i think the 5.38s for around here most of the time will be really useful with the 35" tires. I want to be able to use 4th gear high range from about 40-55 and I think that this will let me do that on the canyon roads that are about 40-45 speed limit.

Another note. I think I may have had some 'clunk' in the rear axle before. It seems a little tighter on and off the gas. Looking at my old pinion it looks like it might have been wearing a little funny maybe? The rear axle was about 40 years old. I also may have had a slight whine on the highway before that has now gone away? I might just be imagining things. The tires and wind noise make it hard to pick out individual noises sometimes.

More testing tomorrow. I still have the 4.30s in the front though so no 4wd stuff till later. I want to get some cycles on the rear axle before the big trip.