Metcalf

Expedition Leader

It felt productive and slow at the same time.....

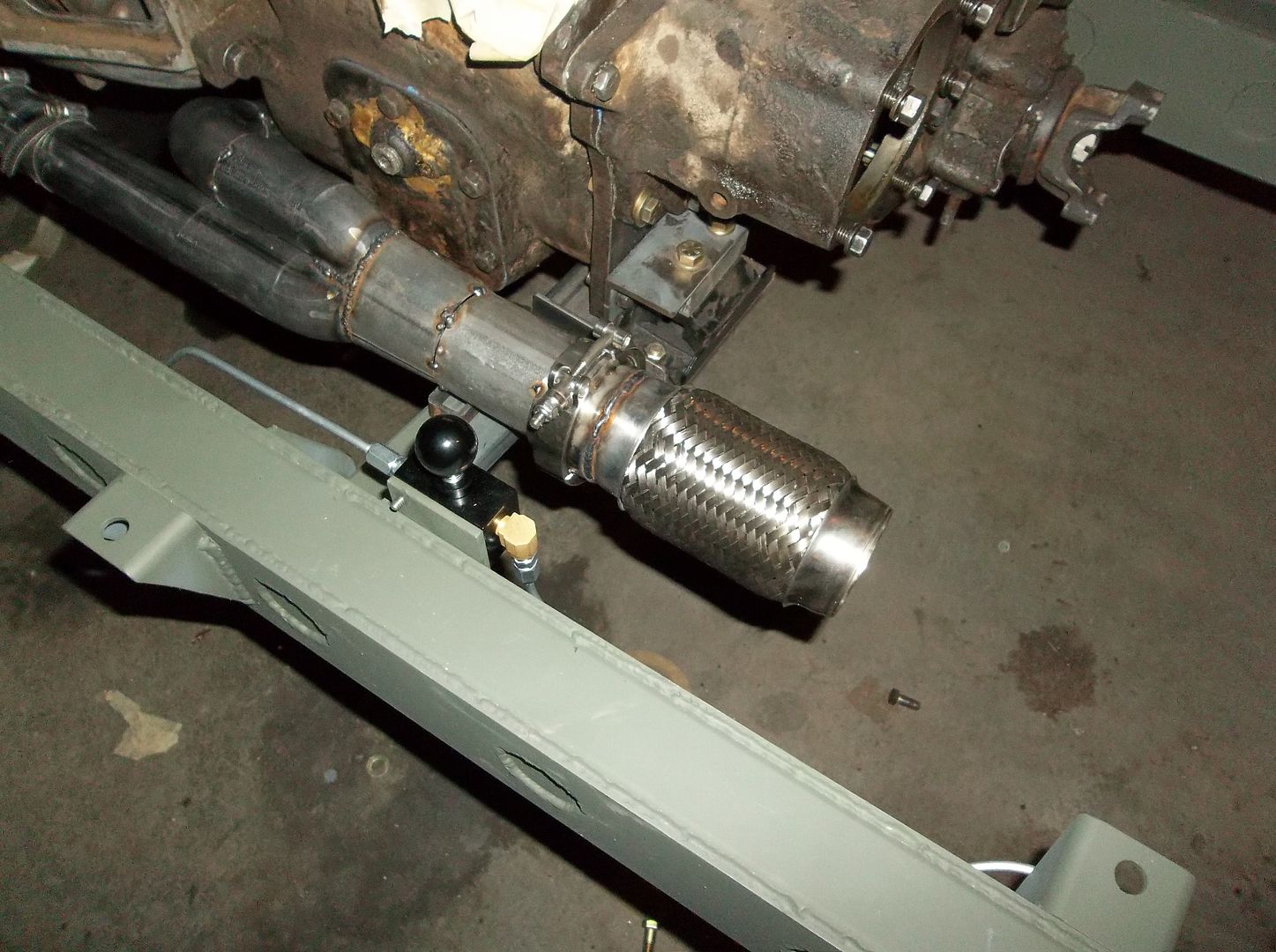

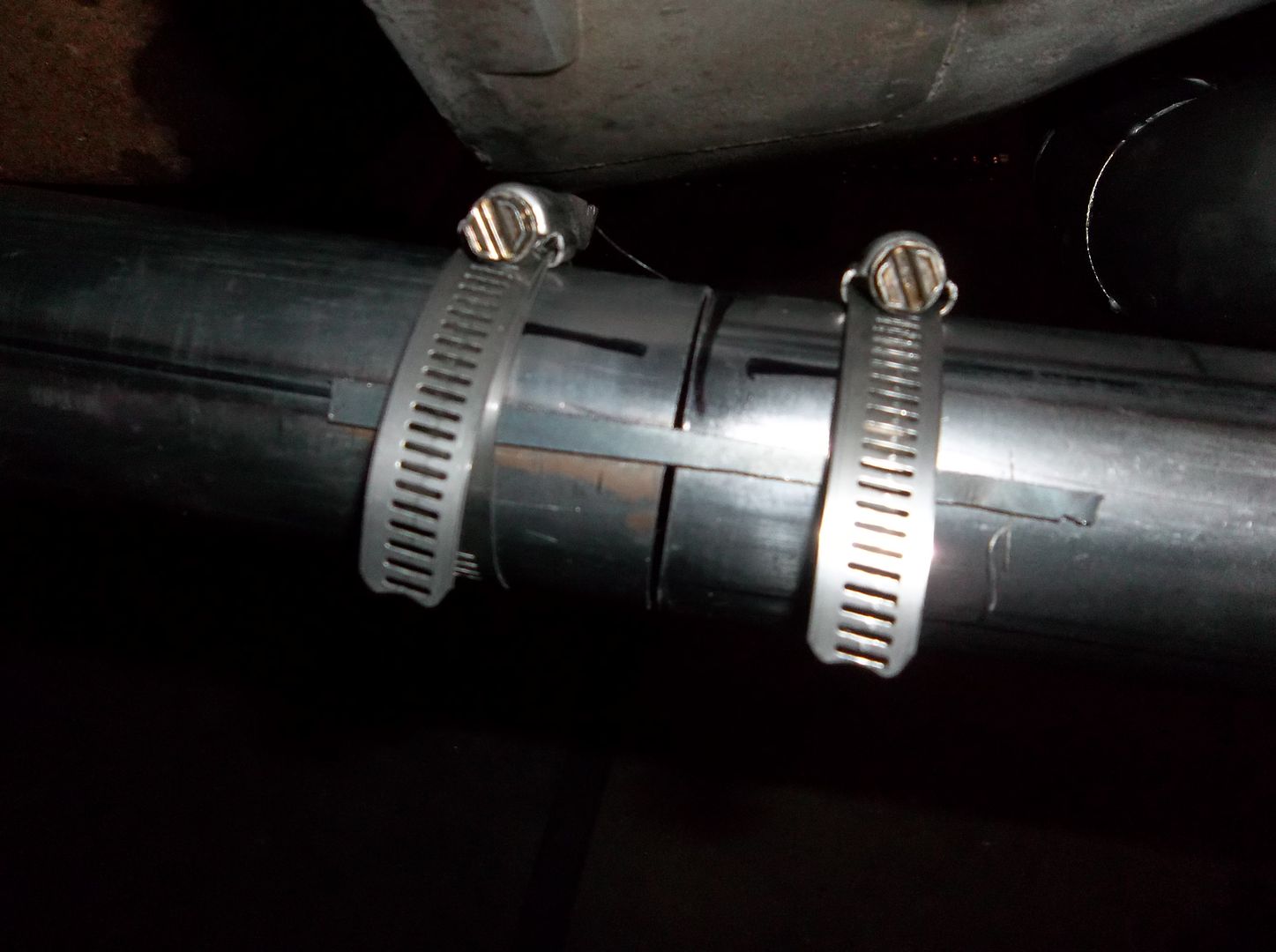

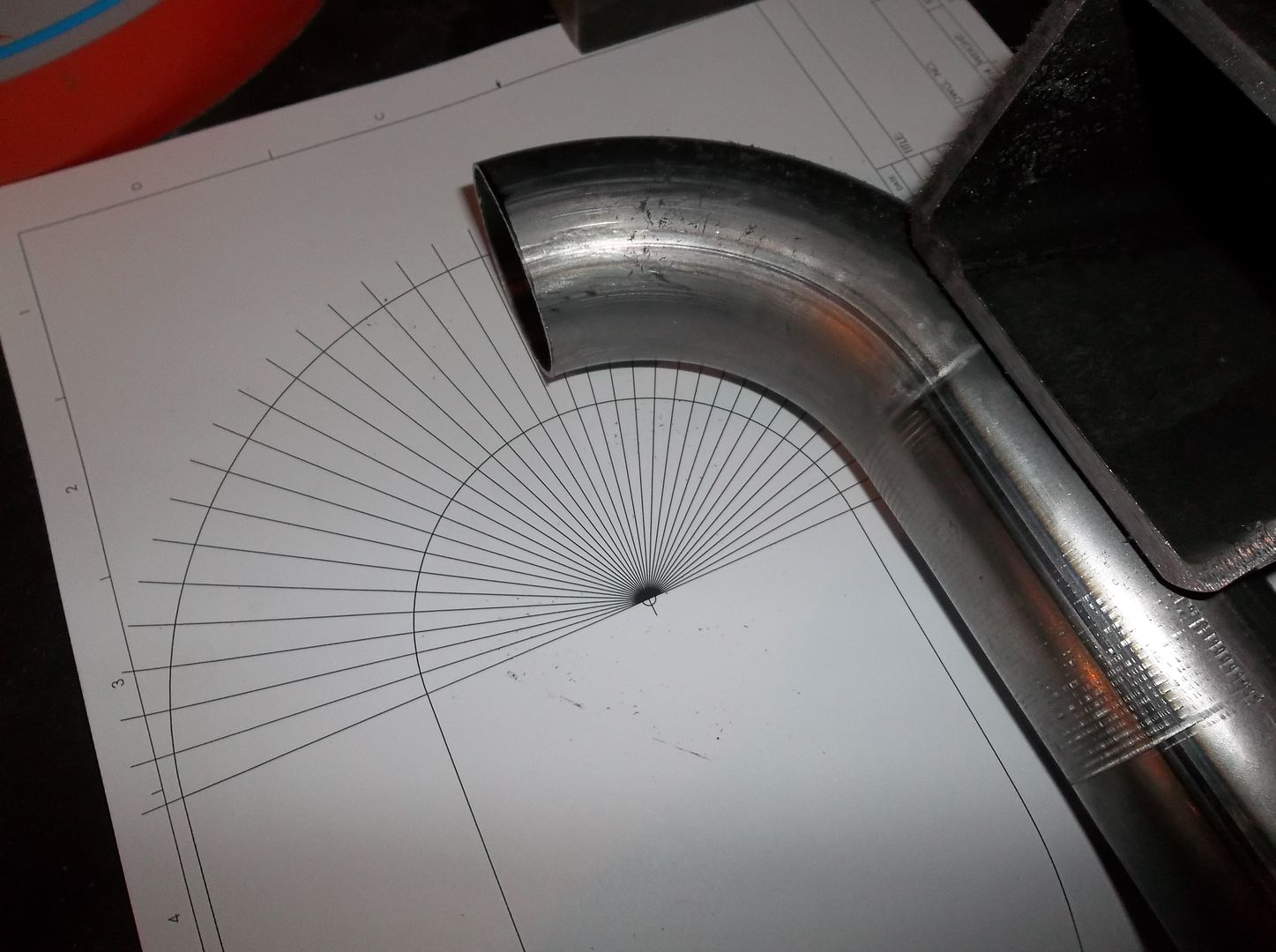

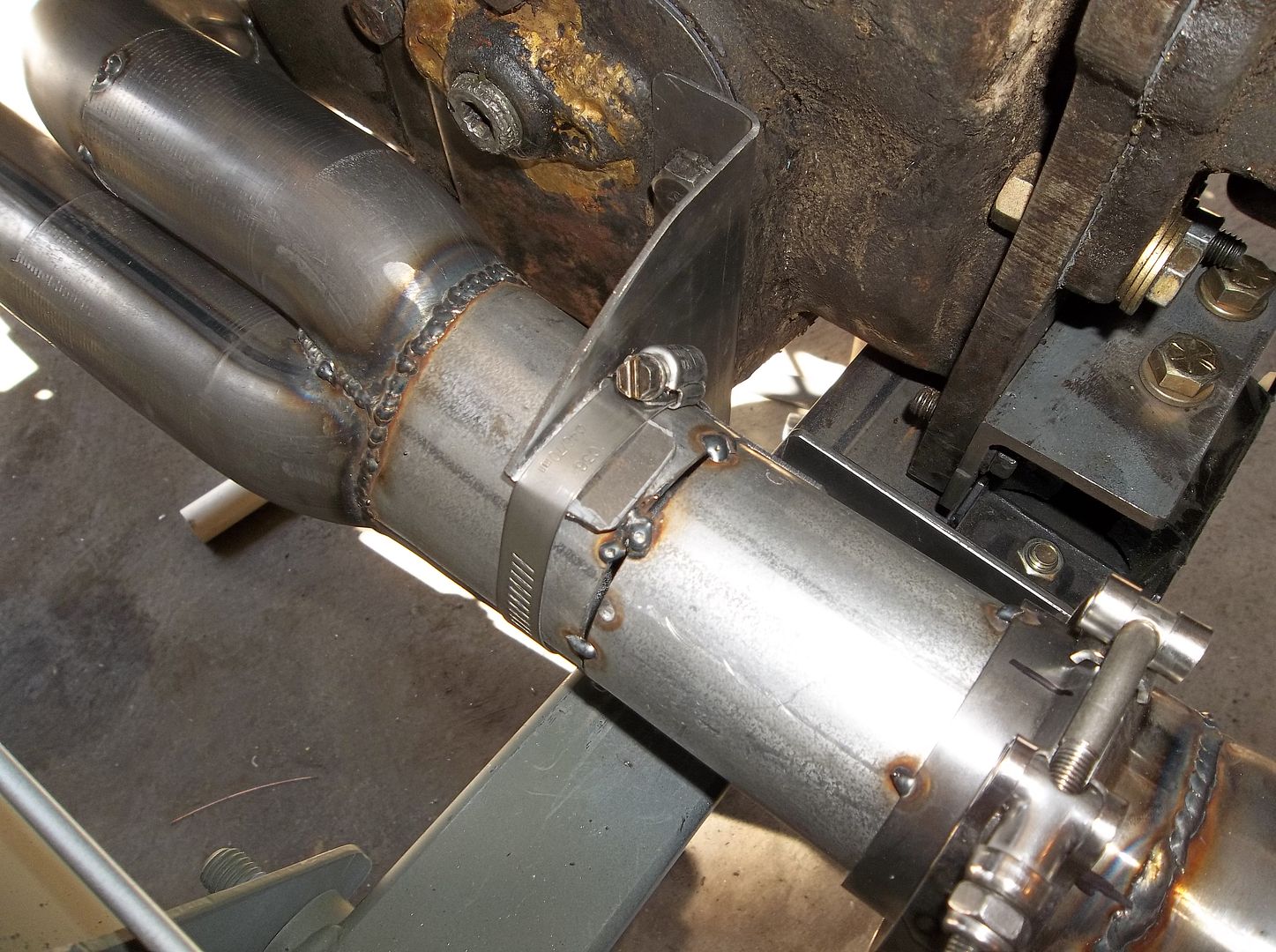

The Y-pipe is almost finished. I only have one more bend to go. I ended up having to make a new flange for the passenger side exhaust manifold so that slowed me down a bit....

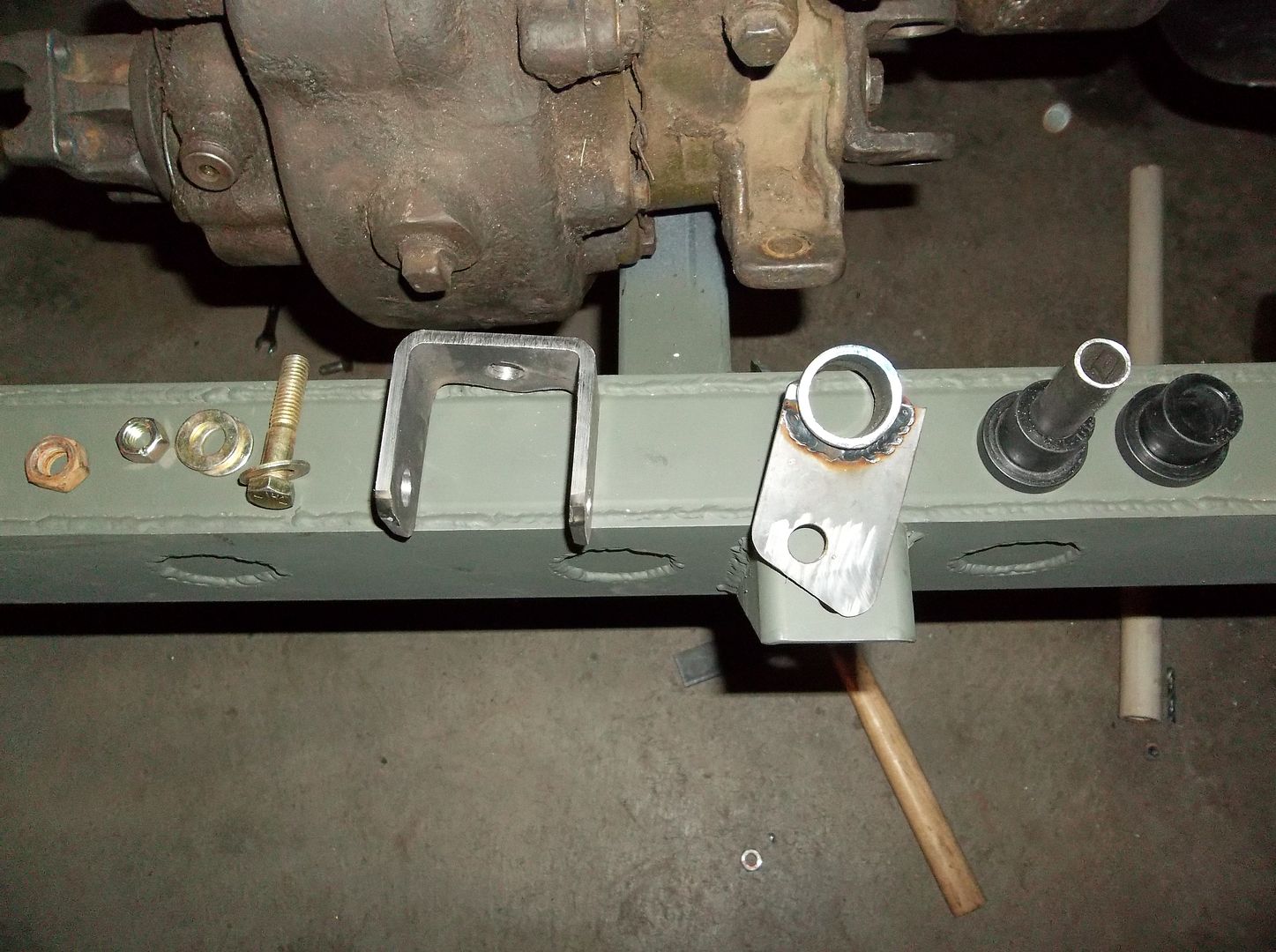

I did get the new 30 spline side gears in my Powr-lok rear diff....

And then I stuck the carrier back in the axle housing and rolled it under the frame.....IT ROLLS AGAIN! Simple pleasures.

Any ideas on where to run the 2.5" rear exhaust and muffler?

I'm going to keep chugging away. I REALLY hope I can get the tub back on the chassis this weekend!

The Y-pipe is almost finished. I only have one more bend to go. I ended up having to make a new flange for the passenger side exhaust manifold so that slowed me down a bit....

I did get the new 30 spline side gears in my Powr-lok rear diff....

And then I stuck the carrier back in the axle housing and rolled it under the frame.....IT ROLLS AGAIN! Simple pleasures.

Any ideas on where to run the 2.5" rear exhaust and muffler?

I'm going to keep chugging away. I REALLY hope I can get the tub back on the chassis this weekend!