Now for the heater (hey I already had all the #'s in front me!)

.

So the propane heaters suitable for heating the van are:

.

Forced-Air furnace like a Suburban or Atwood RV furnance or Propex, Espar, etc.

.

Portable catalytic like a Mr Heater or Buddy Heater, whatever

.

Mounted catatlytic heater like an Olympian Wave, etc

.

I think that's about it.

.

Forced-Air are the safest as they pull outside air for combustion and exhaust their fumes outside. They're the most expensive to operate because they require both propane for heat and electricity for the blower and controls. They're the most difficult to install because you must cut holes in the van, either the floor for a Propex or a wall for the Suburban. and Atwood. Some models require (feature?) ducting for heat distribution which may be great for even heating in large/multi-room RVs but adds to installation complexity. They're the best for moisture introduction into the van because they actually dry the air inside the van by circulating it through a heat exchanger (like a blow dryer for your van). They take up the most room and take it up permanently. They also have thermostats which is nice, because you don’t have to turn them on and off manually.

.

Portable catalytics are not the most dangerous things in the world but they do require ventilation because they use oxygen from within the van for combustion and can deplete it over time and they're prone to being knocked over (they have tipover sensors but they're still hot and can cause damage) or having something accidentally dropped or spilled on them (they're flameless but still capable of ignition). They're efficient to operate because they require only propane, no electric blower. They're easy to install because you just set them down and turn them on, hardly an "installation." The burning of propane creates moisture in the air and thus inside the van. This can lead to condensation on the van walls and glass, basically any cool surface. They take up a good bit of room but can be moved about and removed easily. Most are not connected to external propane tanks and just use 1 lb disposables instead, which is now how’d I prefer it for an extended trip.

.

Mounted catalytics are between portables and furnaces in safety because they're mounted and can't be knocked over and aren't in the floor so can't be spilled onto or inadvertently covered as easily but they do still use oxygen from within the van for combustion and so do require venting. There are supposedly vent-free catalytic heaters (should probably be called self-venting or some such) but I've no experience with them and assume the ducting the vent requires would at least double installation time/energy and be similar to the forced-air furnaces above. They're efficient to operate thanks to needing no electricity and they convert 99.98% of propane used directly to heat as opposed to flame types, with max out at about 76%. Not having a blower also makes them silent. Installation is pretty simple, basically hang it on the wall and connect to gas. Some folks get fancy with cabinet integration. They can cause condensation if not vented sufficiently. They take up the least room of the three (arguable) and depending on installation, can be removed pretty darn easily and used as a portable type by adding optional legs and connecting to other tanks, including 1 lb disposables or left at home during warm months.

.

I've decided on a mounted catalytic Wave as my most likely choice. I do have a portable and will use it if needed before a Wave comes along.

.

EDIT: Not no more! Keep reading!

.

The Olympian Waves come in at least 3 models, a Wave 3, Wave 6, and Wave 8. There may be more but these are the most common and only ones I've found I'd trust. The 3 vary in BTU output and external dimensions but all function the same. CAMCO, manufacturer of the heaters, rates them in both BTU rating and Square Footage they can each heat. I have not found what height of a room is assumed in these square footage calculations but I assume they're all the same so for the sake of comparison, any figure works and I'll use 8' as it's most common for interior walls in homes. The Wave 3 is rated at 130 sq. ft. The Wave 6 is 230 and the Wave 8 for 290. I assume these ratings are for an interior room with no outside walls because this is the way to make the numbers as high as possible, and manufacturers are biased like that. Who ain't?

.

So let's down-rate the figures due to my van having nothing but external walls and some of them single-wall canvas and the others only containing as much insulation as can fit (definitely less than 2/4" walls filled with fiberglass bats with sheetrock on one side and sheathing/siding on the other. I'll say that my van, with its 70" interior height (top popped) and approximate (rounded up and assumed square) external dimensions of 237" long and 80" wide, contains about 349.235 cubic feet of air, minus furnishings and cargo. Why that number? With the 8' ceiling assumption, the Wave models are rated at 1,040 cu ft, 1,840 cu ft and 2,320 cubic feet, respectively. These ratings are of course with heaters set on high and are fairly abritrary given the assumptions and misgivings of the math to get them. Based on these findings however I think the Wave 3 should sufficiently heat a van since it's rated for over double the volume.

.

So that Wave 3 model, let's see how much propane it uses. This is all super tricky and frankly, only quasi-reasonable at best given all the variables of wind, temperature, sunlight, elevation, etc etc etc that a van will see vs a stationary home. Basically, if you want a structure that can be heated efficiently, don't pick a van, especially one with canvas walls. That being said, here are the minimum and maximum amounts of propane and butane and 70/30 mix the heater can use under any normal circumstances:

.

Olympian Wave 3 Heater's lowest setting is 1,600 BTU and its highest is 3,000. Did some math and found that for about $425 I can insulate the van to an average R value of 6.28 and this makes the heat loss 1,946.37 BTU/hr when the van’s 65 inside and 30* outside, which is about as cold as I expect to use the thing more than once. Let's say I want to heat the van for sleeping in only, so 10 hours should let you get ready for bed, into bed, and out the next morning. Whether or not I'd feel safe sleeping (and expect to wake up the next day unasphyxiated) whilst the heater ran remains to be seen but if it's cold enough to want heat all night (would be really really extreme since folks camp in tents with no heat all the time) I'll vent aplenty and hope for the best. Normally I'd expect to heat the van to maybe 70ish before bed, kill the heater, and burrow into my 20*F sleeping bag with my sweetie but let’s see what 10 hours of staying 65* takes: 91,500 BTUs in 1 gallon of propane, divided by 1,950 to keep the can warm = a tenth of a gallon an hour. Do that for 10 hours and you’ve used a gallon. The tank I hope to lasts me 90 summer days 30 winter days is going to last me less than a week doing it that way! Now if the heater could be turned off for half that time and then run 25% higher for the other half, you’d save 25% of the fuel. Turn it off 75% of the time and run it 25% of the time at a 40% higher output and you’d save 65% of the fuel yet theoretically have the same average temperature. If you don’t see what I’m getting at, it’s called Duty Cycle, or the percent of the time something’s being worked vs the percent of time it isn’t. Now that’s great but I really don’t want to drive to South America to sit in my van turning the heater on and off every few minutes to conserve fuel.

.

ENTER THE FORCED-AIR FURNACE!

.

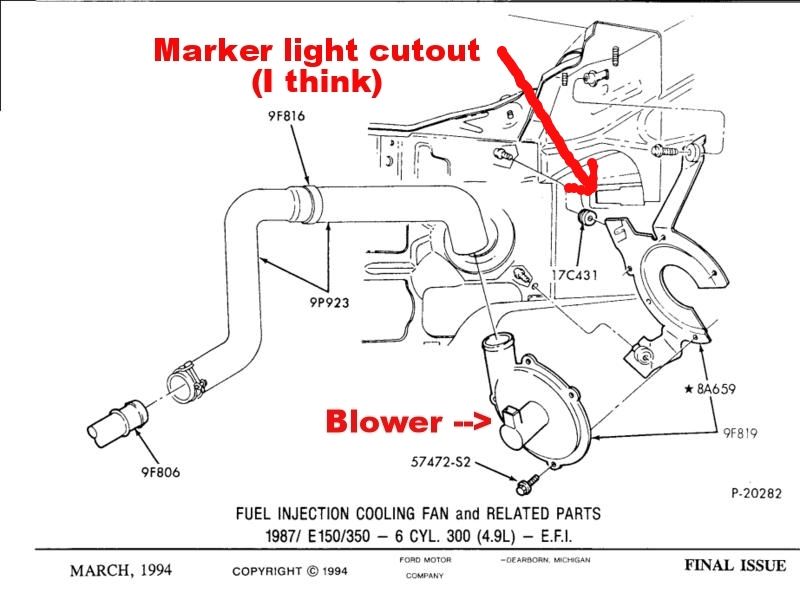

Suburban makes a pretty nice little unit, the NT16SE I think, but it’s 16,000 BTUs and quite large. Too large. It also requires a big (think shoe box) hole cut into the van’s exterior and it requires ducting its output throughout the van, which takes time and energy to do and takes up even more space than just the big furnace itself. Well...poop. As my brother Dave says, “Rejoice, Dear Hearts!” The Atwood Everest Star furnace is available in output ratings of 9,120, 9,160, 12,160, and 13,680 BTU/hr. It’s small, only 11 3/8"H x 8 3/8"W x 20 1/2"D, 23 lbs. Vent cutout size: 2-1/2" H x 4-7/8" W. They can be ducted but don’t have to be. They do require electricity, but it’s under 2 amps on the lowest power model. They also waste heat by blowing their (hot but noxious) exhaust outside, but are still 76% efficient on propane. The lowest power model @ 9,120 BTU output can maintain 65 in an uninsulated van @ about 30% duty cycle, heat it from 30 to 65 in an hour with over 1,000 BTU spare and maintain an insulated van @ 14.6% duty cycle. Best of all, thermostat controlled and fully automatic and totally safe. Like Ron Popeil says, “Set it and forget it.”

.

Now, with regard to consumption, the 8012-II Everest Star furnace @ 9,120 BTU output can maintain an insulated van at 65* in 30* weather @ about 14.6% duty cycle. That means about 9 minutes of an hour (8.88) it's running to hold 65 *in 30 *degree weather. 8.88 minutes x 1.8amps = 15.84 amp minutes, or 0.264AH, which is under 6.5AH per day (6.33) if it stays 30* and you just let ‘er rip, tater chip. Under those same conditions the furnace will burn 12,000 x .148 = 1,776 BTU of propane per hour, or ~2% of a gallon per hour (1.94%) and ~½ a gallon (46.5%) per day, keeping toasty round the clock. Compare that to the catalytic turned down low burning a gallon in 10 hours, or 2.4 gallons a day. 2.4 > .46 in my world.

.

So if you only heated, no cooking, and had 8.25 gallons of propane, that’s over 430 hours of heat, almost 18 days (17.95), during which time it'll use ~113 AH of battery power (but under 7AH a day so very easily replaced daily).

.

In more real-world conditions, like camping in winter where nightly lows are 30-ish and the furnace is run maybe half the day (but having to heat the van up from 30* before bed then keep it 65* through the night), you're looking at about 33% of a gallon burned for heat per day with the top up (30,240 BTUs) and 23% with it down (21,024 BTUs), which extends run time to over 25 and 35 days, respectively, and again, the electrical demand can very easily be overcome with solar, driving, etc.

.

Figured earlier that I can cook plenty of food on 8,400 BTUs per day. Now we know I can heat the van up nicely on 21,024 so a single cold day with home-cooked meals is 29,424 BTUs. That’s 25.7 days without conservation or a warm spell.

.

I remind you these are all worst-case-scenario numbers and that they've now been up-estimated twice. Boiling a lot of water, burning the least efficient fuel available (which you might have to do at elevations over 10,000 ft and/or temps below 32°F), and assuming huge heat losses (as in, no gain from all that cooking inside). There's still a bed for 2 with the top down and since I'll travel with a pretty hot female, that's plenty. "Yeah babe I'm cold too...REAL cold"

.

At current $/gal prices as of Monday, October 27, 2014 that 8 gallons would cost $6.96 USD in Argentina according to the US Energy Information Administration. The annual peak in $/gal prices for propane was $1.10 in April 2014, when a 8 gallon fillup would cost $8.80. You're talking ~$9/month, at the very worst of times. I didn't hand-pick a country with low propane prices; I thought of the montains there and how long I'd probably spend in them and decided that's a likely spot for a fillup. Last month in Mexico propane was .56 per gallon. That means my 21 (COLD) day supply for cooking and heating would run me ~$4.62, or about $6.60 per month of 30* days, and yes it's USD, not pesos. I can handle that. At their 2014 peak, last February, propane prices in Mexico hit $1.44 USD per gallon, so still under $17 per month of 30 degree weather.