volcomsurfer

Adventurer

Backstory:

So for a while now it's been pretty hard to turn my hub from free to locked. I'm no mechanic but I'm learning as I go; unfortunately I learn when things break. I've always been on my own so it's hard to see/check/find issues without having knowledge about stuff. The hub has been hard to turn for a while so I'm assuming I guess I haven't had 4wd for a long time now, coincidently I must have just gotten unstuck when I've had to throw it in 4wd. I got stuck in a parking spot the other day because it iced over while I was at work and couldn't make it over a little hill. I got out, locked the hubs and still only one tire spinning in the rear. My friend was outside the van and said my driveshaft was spinning but not the wheels. So I came home and opened up the hub to find out it's all rusted and dry. Further more the seal going to the axle was out.

Things I've checked:

-I've lifted the DS tire off the ground, locked it and spun the driveshaft, the wheel spins. Did the same for the PS and it doesn't spin. Because the knuckle assembly moves so much I don't think it's sitting centered so the hub wasn't actually engaging

-All the teeth on the gears of the hub assembly are in tack and nothing is chipped

-The springs are rusted and don't have much resistance

-The diff is fluid level is fine

-The o-ring on the hub cap looks intact so I'm assuming the grease and moisture was coming from the back

-The driver side hub assembly is clean and looks fine

Questions:

-I know it's probably hard to tell me without seeing it, but should I be able to just clean all the surface rust off the hub assembly and get new springs if need be and keep the hub? or will I need to get a whole new one?

-What's the best method of checking everything to see what parts are shot and what I need to order?

-What's my next step?

I've done some searching but I'm not really finding a definitive answer for what I should do. I just spent a bunch of money on an oil cooler issue and transfer case/u-joint issues and I'm trying to do this cheap but right (more right than cheap). If there's any other info you guys need to help me diagnose what I'll have to do lemme know. I appreciate your time in reading this and giving me advice.

Video of the knuckle play..

https://youtu.be/82ERStsYjcI

Passenger side assembly:

A little piece that was stuck inbetween some teeth. I assumed this was one of the issues with it not engaging. It took a bit of effort to pop it out.

The seal:

Driverside, so THAT's what it's supposed to look like...:

So for a while now it's been pretty hard to turn my hub from free to locked. I'm no mechanic but I'm learning as I go; unfortunately I learn when things break. I've always been on my own so it's hard to see/check/find issues without having knowledge about stuff. The hub has been hard to turn for a while so I'm assuming I guess I haven't had 4wd for a long time now, coincidently I must have just gotten unstuck when I've had to throw it in 4wd. I got stuck in a parking spot the other day because it iced over while I was at work and couldn't make it over a little hill. I got out, locked the hubs and still only one tire spinning in the rear. My friend was outside the van and said my driveshaft was spinning but not the wheels. So I came home and opened up the hub to find out it's all rusted and dry. Further more the seal going to the axle was out.

Things I've checked:

-I've lifted the DS tire off the ground, locked it and spun the driveshaft, the wheel spins. Did the same for the PS and it doesn't spin. Because the knuckle assembly moves so much I don't think it's sitting centered so the hub wasn't actually engaging

-All the teeth on the gears of the hub assembly are in tack and nothing is chipped

-The springs are rusted and don't have much resistance

-The diff is fluid level is fine

-The o-ring on the hub cap looks intact so I'm assuming the grease and moisture was coming from the back

-The driver side hub assembly is clean and looks fine

Questions:

-I know it's probably hard to tell me without seeing it, but should I be able to just clean all the surface rust off the hub assembly and get new springs if need be and keep the hub? or will I need to get a whole new one?

-What's the best method of checking everything to see what parts are shot and what I need to order?

-What's my next step?

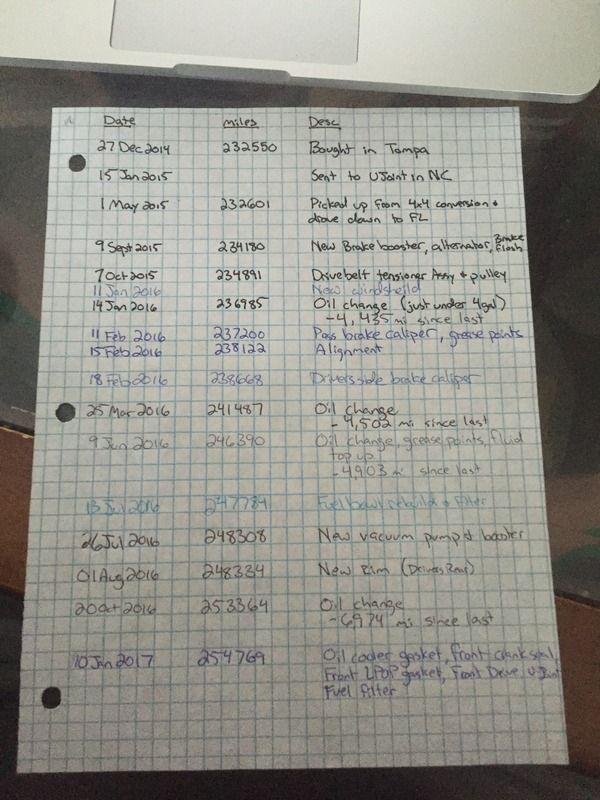

I've done some searching but I'm not really finding a definitive answer for what I should do. I just spent a bunch of money on an oil cooler issue and transfer case/u-joint issues and I'm trying to do this cheap but right (more right than cheap). If there's any other info you guys need to help me diagnose what I'll have to do lemme know. I appreciate your time in reading this and giving me advice.

Video of the knuckle play..

https://youtu.be/82ERStsYjcI

Passenger side assembly:

A little piece that was stuck inbetween some teeth. I assumed this was one of the issues with it not engaging. It took a bit of effort to pop it out.

The seal:

Driverside, so THAT's what it's supposed to look like...: