ColoDisco

Explorer

Well after a year I finally rebuilt my diff. With help from my good friend Morris we were able to sneak the diff out. My exhaust is welded as one piece thanks to the idiot who put on the full magnaflow with cats and destroyed my manifolds, but that's another story and will be corrected this winter.

Amazing that there wasn't more bearing damage considering l knew they were worn and kept driving on them figuring if it ever got louder I would address it immediately. Never did.

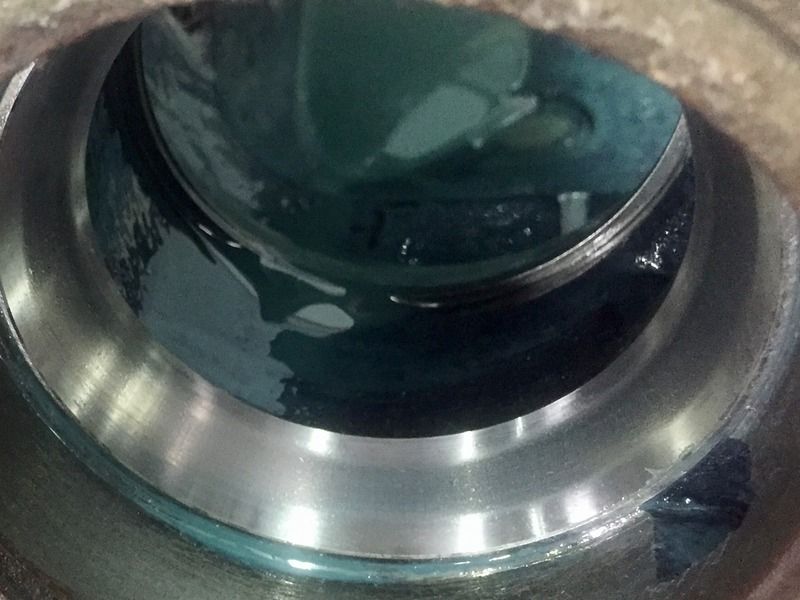

In case you are wondering the green lube is redline shockproof lightweight. It was recommended to me but in hindsight I wish I had kept with factory fluid. I switched back to factory fluid and will be changing it regularly.

After removing the diff and removing the case bolts:

First look inside housing. Can see the paint peeling inside. I ran the whole setup through the parts washer and sandblasted inside the case while it was completely disassembled:

Cover after the parts washer. Again I sandblasted off the remaining paint:

Moisture inside the case which mixed with the shockproof causing a thick slime. No doubt moisture had a role in the degradation of the bearings:

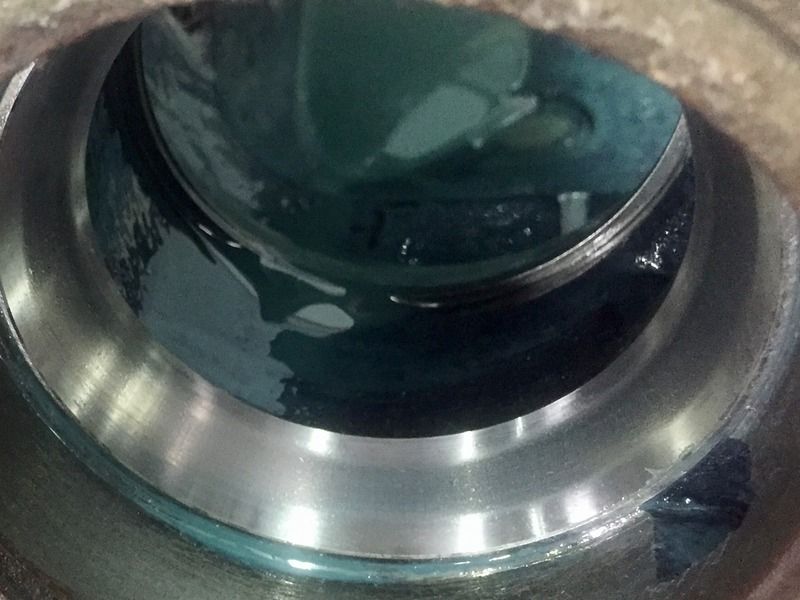

Race wear:

This is the worst bearing. It was the right output bearing:

Installation of the PDR kit was easy. You need a shop press some race drivers that fit (I improvised from a hub tamer kit) and a bearing splitter and removal pullers. Overall it took me 8-9 hours but I added some clean up of the case and had to deal with a one piece exhaust. Well that and I was on day 6 of automotive repair. Noise is gone. Diff works well. On a DIY list I would rate it as difficult. I have a complete shop at my disposal and the instructions are almost non existent. If you have done diffs ( this was my fifth including a 2016 Range Rover) then you should be fine. You need to know what kind of tension should be on the pinion as there is no spec sheet from the factory.

HUGE thank you to Todd (unseenone)!! He was instrumental on me getting this done. I will be buying the front kit in June (preemptive rebuild as I am closing in on 200k).

Amazing that there wasn't more bearing damage considering l knew they were worn and kept driving on them figuring if it ever got louder I would address it immediately. Never did.

In case you are wondering the green lube is redline shockproof lightweight. It was recommended to me but in hindsight I wish I had kept with factory fluid. I switched back to factory fluid and will be changing it regularly.

After removing the diff and removing the case bolts:

First look inside housing. Can see the paint peeling inside. I ran the whole setup through the parts washer and sandblasted inside the case while it was completely disassembled:

Cover after the parts washer. Again I sandblasted off the remaining paint:

Moisture inside the case which mixed with the shockproof causing a thick slime. No doubt moisture had a role in the degradation of the bearings:

Race wear:

This is the worst bearing. It was the right output bearing:

Installation of the PDR kit was easy. You need a shop press some race drivers that fit (I improvised from a hub tamer kit) and a bearing splitter and removal pullers. Overall it took me 8-9 hours but I added some clean up of the case and had to deal with a one piece exhaust. Well that and I was on day 6 of automotive repair. Noise is gone. Diff works well. On a DIY list I would rate it as difficult. I have a complete shop at my disposal and the instructions are almost non existent. If you have done diffs ( this was my fifth including a 2016 Range Rover) then you should be fine. You need to know what kind of tension should be on the pinion as there is no spec sheet from the factory.

HUGE thank you to Todd (unseenone)!! He was instrumental on me getting this done. I will be buying the front kit in June (preemptive rebuild as I am closing in on 200k).