TRIARII

Adventurer

rayra: I certainly would like to talk more in depth with you over the phone or via email about a possible arrangement. That said Im not in a immediate rush to get the drawer system though Id like to get some plans started.

To clear up some confusion for other folks on here. I have completely removed the second row seating assembly from my vehicle. So when I say length I mean a drawer system that stretches from directly behind the front passenger seat, all the way to the rear cargo do. I do alot of camping with my rig and I can assure you folks that their is plenty of room for me to sprawl out in, play on my laptop or cook a good meal. As for the plastic drawers. I believe the best way to figure out what works and what does not work is to experiment. Go camping. Test out your kit and see what works and what could be changed or improved. Same thing can be said for determining a practical quantity of your kit. I wanted to experiment with the plastic drawers I found at Walmart to see if they could be a practical substitute for a heavy duty drawer system. On paper it looked good but after a week of use the drawers began to bend, crack, snap and break. The drawers were dirt cheap and I now know that I need something much stronger.

Regarding construction materials and cost. Ive see alot of folks constructing elaborate drawer systems made out of plywood, marine grade wood or other heavier materials none of which tickle my fancy. I was introduced to aluminum extrusion while working a seasonal job at a submarine cable factory. One of the departments I was working in manufactures the repeaters for the cables. These repeaters cost a fortune to manufacture and weigh in at 2000 lbs. Moving the repeaters around the department for assembly would be a pain in the butt had it not been for these lightweight yet strong aluminum carts.

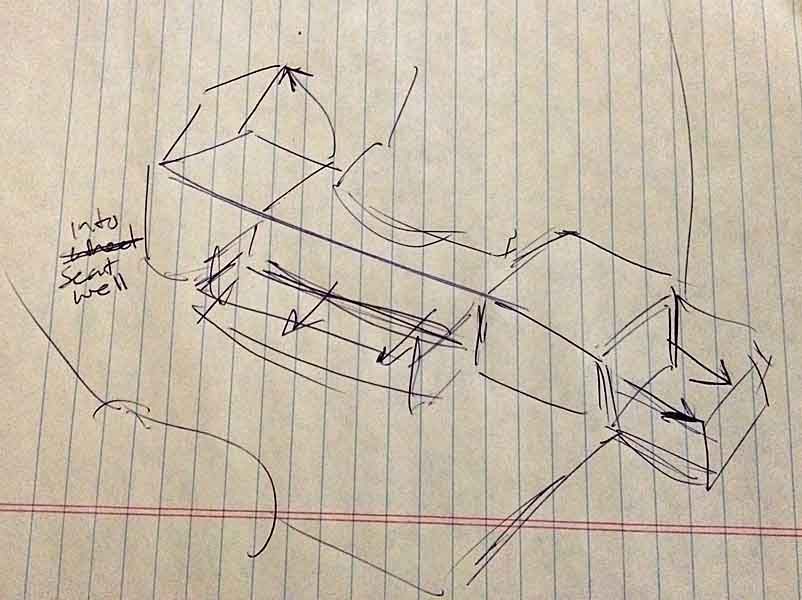

Thus I'd like to utilize aluminum extrusion as the primary building material for my drawer system. From the little research I did on suppliers of this material, its affordable and easier to assemble than sheets of plywood via locking tabs. The only question is how to cut the material and how to build the actual sliding drawers. Rather than contouring the drawer system to the exact shape and curves in the cargo area behind the front seats, I think a simple rectangular shaped drawer system would be the best approach. Fewer measurements needed and less labor time. Fully assembled a rectangular drawer system would be light enough that it can be easily positioned inside the truck or removed without risk of injury or the need of a helper. Apply some Discovery carpeting to the drawer to make it look clean, latching points and a solid thin piece of metal or fiberglass on top for the counter top surface and call it good.

To clear up some confusion for other folks on here. I have completely removed the second row seating assembly from my vehicle. So when I say length I mean a drawer system that stretches from directly behind the front passenger seat, all the way to the rear cargo do. I do alot of camping with my rig and I can assure you folks that their is plenty of room for me to sprawl out in, play on my laptop or cook a good meal. As for the plastic drawers. I believe the best way to figure out what works and what does not work is to experiment. Go camping. Test out your kit and see what works and what could be changed or improved. Same thing can be said for determining a practical quantity of your kit. I wanted to experiment with the plastic drawers I found at Walmart to see if they could be a practical substitute for a heavy duty drawer system. On paper it looked good but after a week of use the drawers began to bend, crack, snap and break. The drawers were dirt cheap and I now know that I need something much stronger.

Regarding construction materials and cost. Ive see alot of folks constructing elaborate drawer systems made out of plywood, marine grade wood or other heavier materials none of which tickle my fancy. I was introduced to aluminum extrusion while working a seasonal job at a submarine cable factory. One of the departments I was working in manufactures the repeaters for the cables. These repeaters cost a fortune to manufacture and weigh in at 2000 lbs. Moving the repeaters around the department for assembly would be a pain in the butt had it not been for these lightweight yet strong aluminum carts.

Thus I'd like to utilize aluminum extrusion as the primary building material for my drawer system. From the little research I did on suppliers of this material, its affordable and easier to assemble than sheets of plywood via locking tabs. The only question is how to cut the material and how to build the actual sliding drawers. Rather than contouring the drawer system to the exact shape and curves in the cargo area behind the front seats, I think a simple rectangular shaped drawer system would be the best approach. Fewer measurements needed and less labor time. Fully assembled a rectangular drawer system would be light enough that it can be easily positioned inside the truck or removed without risk of injury or the need of a helper. Apply some Discovery carpeting to the drawer to make it look clean, latching points and a solid thin piece of metal or fiberglass on top for the counter top surface and call it good.