Littleredridinghood

New member

Hello!

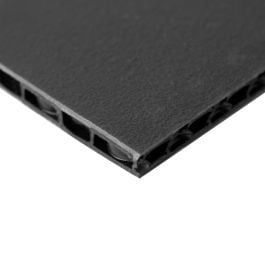

We are beginning our Unimog camper build which has a composite box on the back. The composite box was our first foray into the world of composites and it now has me thinking about our cabinet construction. I can weld and was planning on welding together aluminum angle and skinning it with plywood. However now I'm considering just building the cabinets out of something other than wood altogether. I'm not a huge fan of 80/20. I find it bulky and don't want to pay the high $$ cost when I could just weld together some aluminum we have here at our shop. We've completed 3 other camper builds and up to this point most of my cabinets have been traditional 1/2" plywood construction. I came across Coosa Bluewater and thought it was perfect, but the price had me running.

I would love to do a cabinet construction like this:

however I just cant afford 0.5" Coosa at $330 a sheet. Does anyone know of any alternatives?

Whatever product I use needs to be paintable with a final look similar to plywood, not be too complicated to fasten together, lighter than plywood, structurally strong enough to hold our refrigerator, oven, stove, drawers etc., available in the US market, hold up to the stresses of overlanding/our articulating camper box, and I'd like to make overhead cabinets out of it as well to keep the weight down at the top of the box.

Products I've come across in my research:

Thermo-Lite Board (similar to Coosa in cost): https://www.spaceagesynthetics.com/thermo-lite-board-product-line

Starboard (still pretty heavy): https://www.kingplastic.com/products/king-starboard-st/

AZEK PVC panels: https://www.homedepot.com/p/AZEK-0-5-in-x-4-ft-x-8-ft-White-PVC-Sheet-ARS01248096/315583746

Carbon-Core Carbon Foam Reinforced Panel: https://www.carbon-core.com/products/carbonfoam-structural-foams/fiber-reinforced-panel/

Does anyone have any suggestions for alternatives to Coosa Bluewater? Or do I need to bite the bullet and just use Coosa?

We are beginning our Unimog camper build which has a composite box on the back. The composite box was our first foray into the world of composites and it now has me thinking about our cabinet construction. I can weld and was planning on welding together aluminum angle and skinning it with plywood. However now I'm considering just building the cabinets out of something other than wood altogether. I'm not a huge fan of 80/20. I find it bulky and don't want to pay the high $$ cost when I could just weld together some aluminum we have here at our shop. We've completed 3 other camper builds and up to this point most of my cabinets have been traditional 1/2" plywood construction. I came across Coosa Bluewater and thought it was perfect, but the price had me running.

I would love to do a cabinet construction like this:

however I just cant afford 0.5" Coosa at $330 a sheet. Does anyone know of any alternatives?

Whatever product I use needs to be paintable with a final look similar to plywood, not be too complicated to fasten together, lighter than plywood, structurally strong enough to hold our refrigerator, oven, stove, drawers etc., available in the US market, hold up to the stresses of overlanding/our articulating camper box, and I'd like to make overhead cabinets out of it as well to keep the weight down at the top of the box.

Products I've come across in my research:

Thermo-Lite Board (similar to Coosa in cost): https://www.spaceagesynthetics.com/thermo-lite-board-product-line

Starboard (still pretty heavy): https://www.kingplastic.com/products/king-starboard-st/

AZEK PVC panels: https://www.homedepot.com/p/AZEK-0-5-in-x-4-ft-x-8-ft-White-PVC-Sheet-ARS01248096/315583746

Carbon-Core Carbon Foam Reinforced Panel: https://www.carbon-core.com/products/carbonfoam-structural-foams/fiber-reinforced-panel/

Does anyone have any suggestions for alternatives to Coosa Bluewater? Or do I need to bite the bullet and just use Coosa?