SBSYNCRO

Well-known member

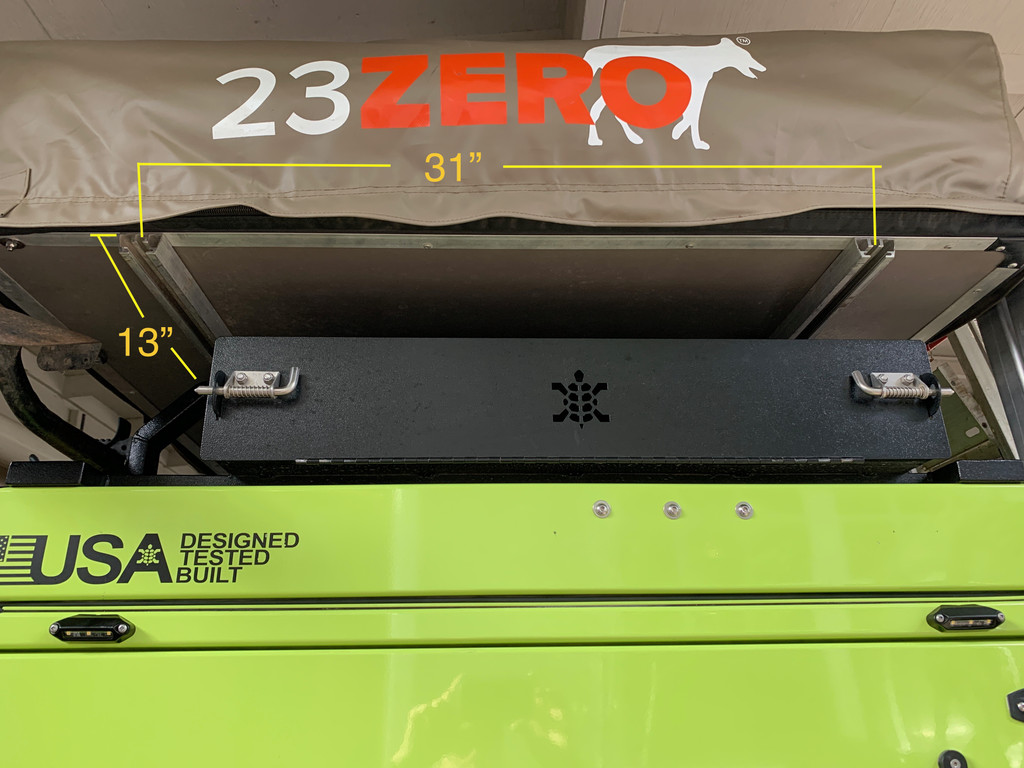

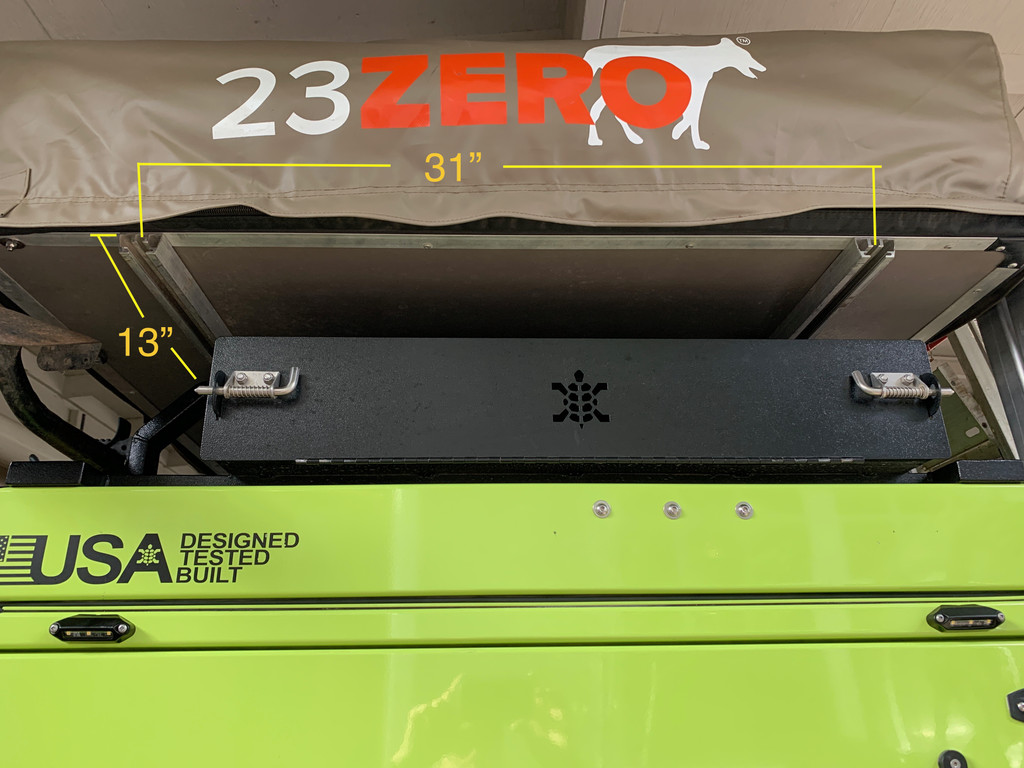

Posting here because I have almost zero experience with using aluminum channel for projects, and I'm hoping someone with more experience will know the most efficient way to do this.. On the back of my Turtleback trailer, the aluminum rails that the RTT mounts to end just flush with the tailgate. In order to provide some better overhead lighting for the galley, I'm thinking of some sort of "light bar" that would slide out and lock with a couple of plunger type pins (like on RTT ladders).

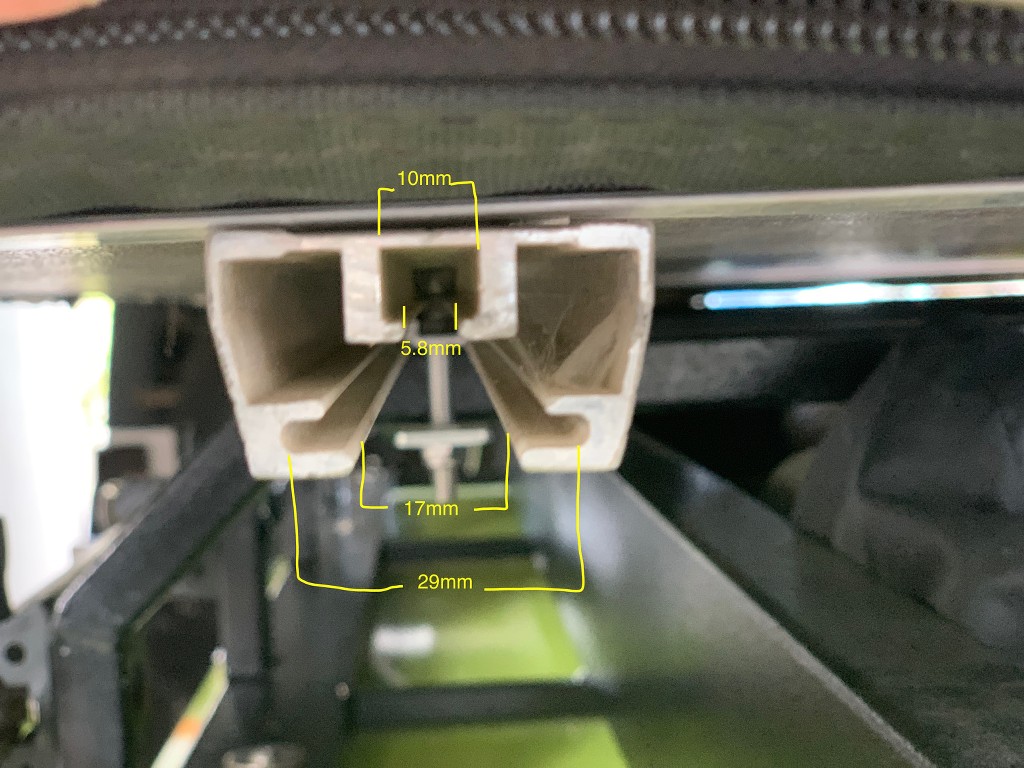

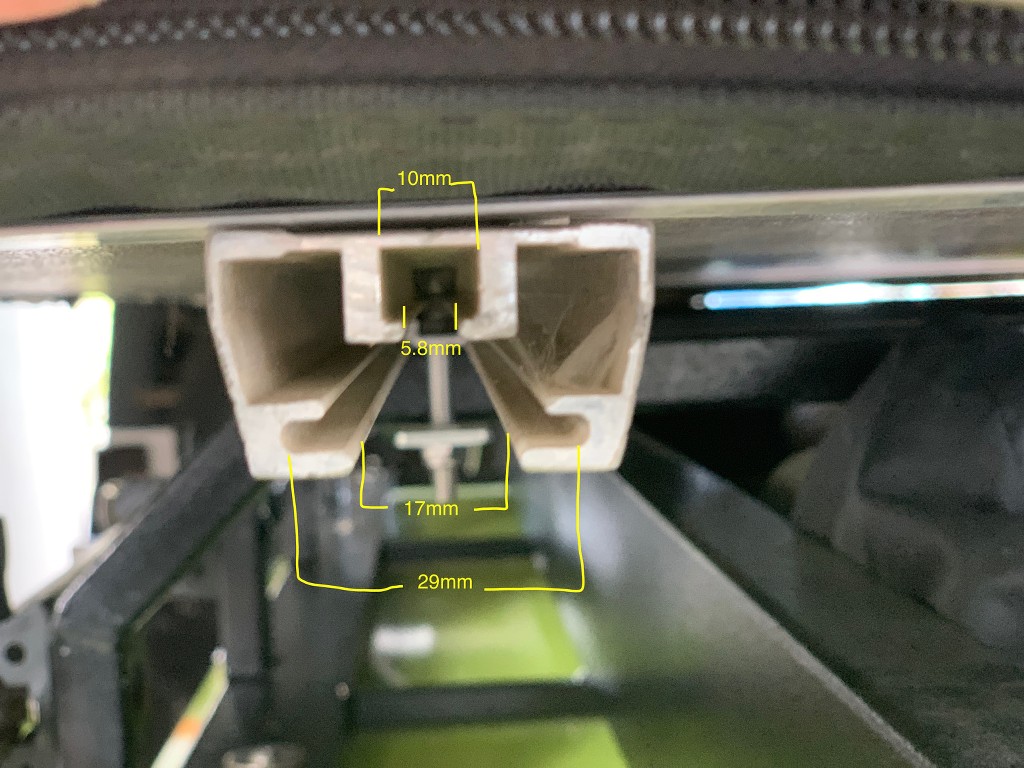

Here are the dimensions of the aluminum extrusions (forgive the mix-up between metric and standard - I happened to have a carpenter's tape measure handy and was too lazy to go get my metric one). I'm thinking some 1/8" x 1" aluminum bar stock that would slide inside the 29mm slot and then maybe secure with a thumb screw secured to a T-nut inside the 10mm slot. (But because of road vibration, I'd prefer some sort of plunger/pin arrangement). I'd want it to slide out about 10" and there would be a horizontal aluminum bracket that spans the 31" distance between the two (this would become the overhead light mount). The bar stock would be about 14" long, bent to a 90º at the 12" mark, leaving a 2" long mounting surface, across which I would span another piece of aluminum bar stock or extruded channel like 80/20.

Any other suggestions?

Here are the dimensions of the aluminum extrusions (forgive the mix-up between metric and standard - I happened to have a carpenter's tape measure handy and was too lazy to go get my metric one). I'm thinking some 1/8" x 1" aluminum bar stock that would slide inside the 29mm slot and then maybe secure with a thumb screw secured to a T-nut inside the 10mm slot. (But because of road vibration, I'd prefer some sort of plunger/pin arrangement). I'd want it to slide out about 10" and there would be a horizontal aluminum bracket that spans the 31" distance between the two (this would become the overhead light mount). The bar stock would be about 14" long, bent to a 90º at the 12" mark, leaving a 2" long mounting surface, across which I would span another piece of aluminum bar stock or extruded channel like 80/20.

Any other suggestions?

Last edited: