compactcamping

Explorer

Thought people might be interested in seeing the build of my new “off-pavement” camping trailer. This isn’t meant as a hardcore off-road trailer, it’s for towing on gravel / forest service roads. It will run a “soft-ride” leaf spring suspension. It’s designed to be Tent Topped with a main rear storage area sized for Arko-Mils lidded storage boxes and a nose box storage area. The trailer box will be built out of plywood, based on my planned usage; this should be more than strong enough.

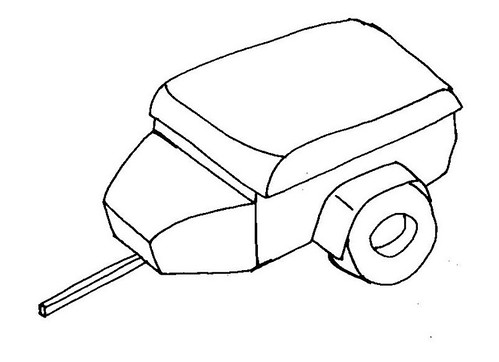

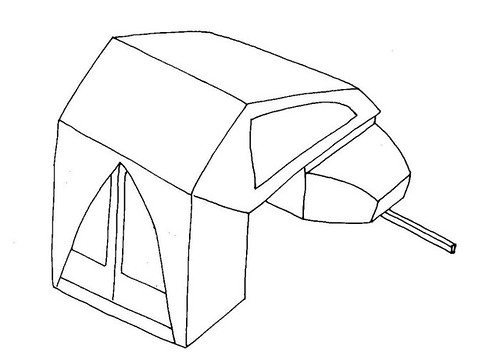

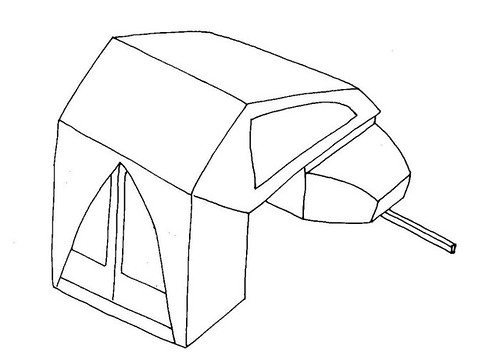

Here are sketches of the basic idea.

I’m building backwards from what most people do. First, I’m building the trailer box on a flat bed trailer I have, then I’ll build the frame. The basic build approach is to create the main box structure, then the rear overhang and access door area; next move to the front, creating the overhang and the nose box. I’ll then build the nose box lid, seal the inside and put the top on. The final step will be to seal the exterior with Durabak.

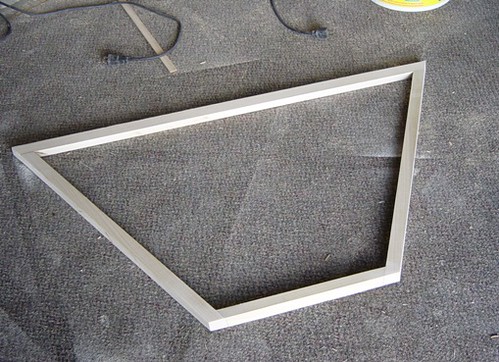

I began by cutting out the floor. The nose box sides have a 60 degree angle and are set in 1”. The 60 degree angle corresponds to the tongue a-frame braces. Next I added the corner blocks to the floor to which the walls will attach.

I added the front wall. Before attaching it, I added a portion of the overhang structure. I made the walls 24”, maximizing material usage and providing proper clearance for the Arko-Mils storage boxes I plan on using

Here is a close up of the front overhang partial built.

Here is a close up of the corner blocks

Here are sketches of the basic idea.

I’m building backwards from what most people do. First, I’m building the trailer box on a flat bed trailer I have, then I’ll build the frame. The basic build approach is to create the main box structure, then the rear overhang and access door area; next move to the front, creating the overhang and the nose box. I’ll then build the nose box lid, seal the inside and put the top on. The final step will be to seal the exterior with Durabak.

I began by cutting out the floor. The nose box sides have a 60 degree angle and are set in 1”. The 60 degree angle corresponds to the tongue a-frame braces. Next I added the corner blocks to the floor to which the walls will attach.

I added the front wall. Before attaching it, I added a portion of the overhang structure. I made the walls 24”, maximizing material usage and providing proper clearance for the Arko-Mils storage boxes I plan on using

Here is a close up of the front overhang partial built.

Here is a close up of the corner blocks