After a lot of reading, I bought a M416 (really good condition w/ minor surface rust) to turn into a off road/overland trailer.

My question to all the DIYers... What tools did you use throughout the project? Good/bad ones? Were there any you felt you did not end up needing?

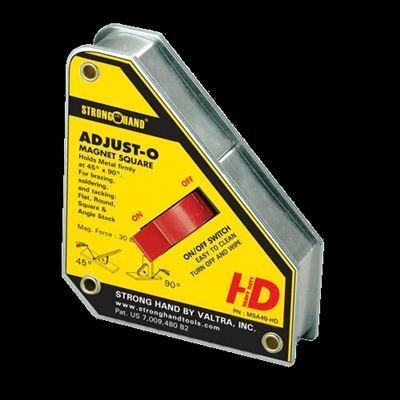

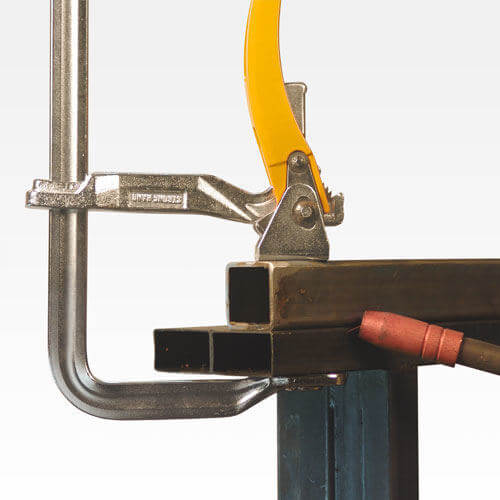

I have plenty of sockets, wrenches, screwdrivers, circular saw, drill, etc... (what I would consider the "normal" stuff) and will be taking a basic welding class soon. I have done form carpentry in the past, but metalwork will be new to me.

As I said, I have read a LOT, but haven't really noticed the tool aspect of the builds covered.

Thanks for the help and for the wealth of information throughout the site

My question to all the DIYers... What tools did you use throughout the project? Good/bad ones? Were there any you felt you did not end up needing?

I have plenty of sockets, wrenches, screwdrivers, circular saw, drill, etc... (what I would consider the "normal" stuff) and will be taking a basic welding class soon. I have done form carpentry in the past, but metalwork will be new to me.

As I said, I have read a LOT, but haven't really noticed the tool aspect of the builds covered.

Thanks for the help and for the wealth of information throughout the site