Wild Coast

Member

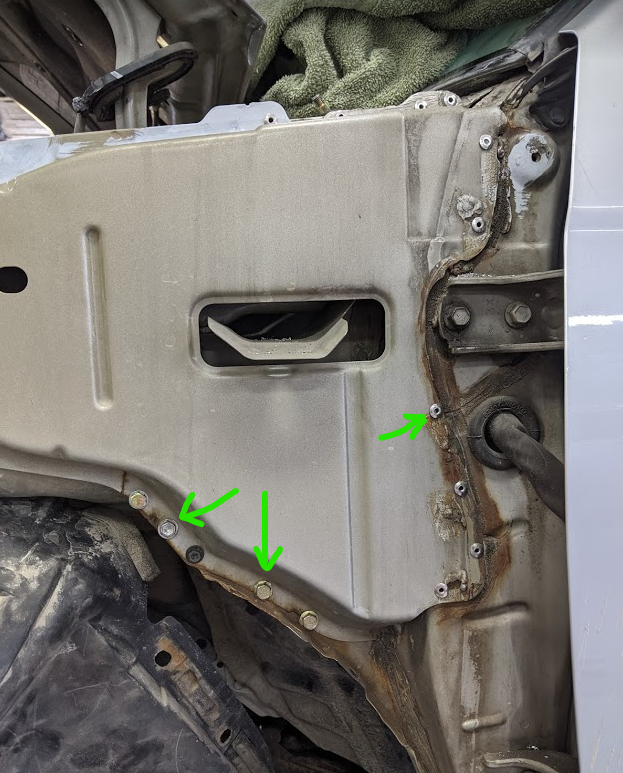

So I'm getting slowly growing cracks in my radiator support, anyone else experiencing this on off-road vehicles?

Some examples, my 2004 Xterra (2" body lift, 3" suspension lift)

Has anyone else experience this?

I'm assuming it's partially to do with driving offroad (rattly logging roads for hours) as well as the fact that I'm running a 2" body lift... those 2" rubber body pucks mean the frame has that much more ability to flex and stress the thin sheet metal.

I talked to a body shop and they said they could braze them but it will likely only be temporary and will likely happen again b/c of the body lift. Any thoughts? Any way that anyone has seen these get reinforced?

Some examples, my 2004 Xterra (2" body lift, 3" suspension lift)

Has anyone else experience this?

I'm assuming it's partially to do with driving offroad (rattly logging roads for hours) as well as the fact that I'm running a 2" body lift... those 2" rubber body pucks mean the frame has that much more ability to flex and stress the thin sheet metal.

I talked to a body shop and they said they could braze them but it will likely only be temporary and will likely happen again b/c of the body lift. Any thoughts? Any way that anyone has seen these get reinforced?