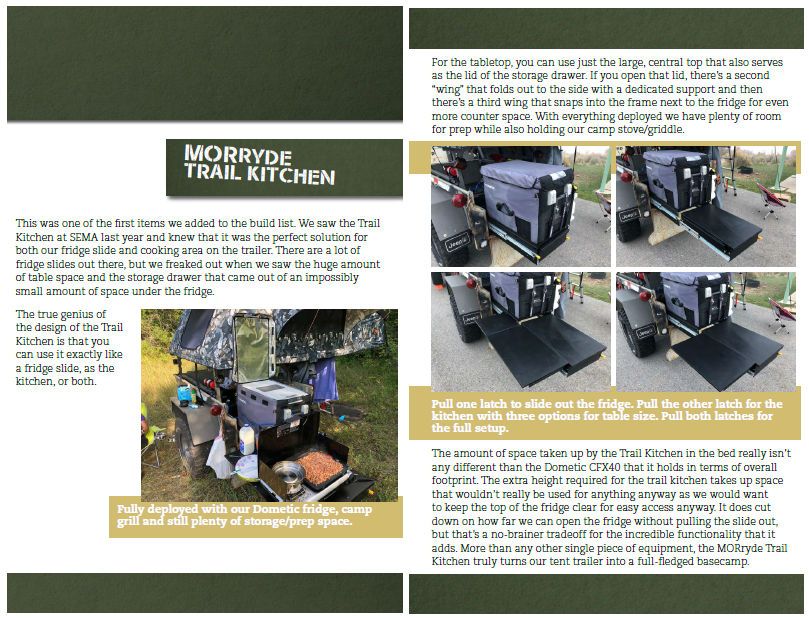

A part of the storage bag designs I did for the startup company is a tailgate panel, the idea is that many of the bags they do could attach there. For example, the backpack bag, which attaches to the back of the seat, would also work on the tailgate, here's a concept image:

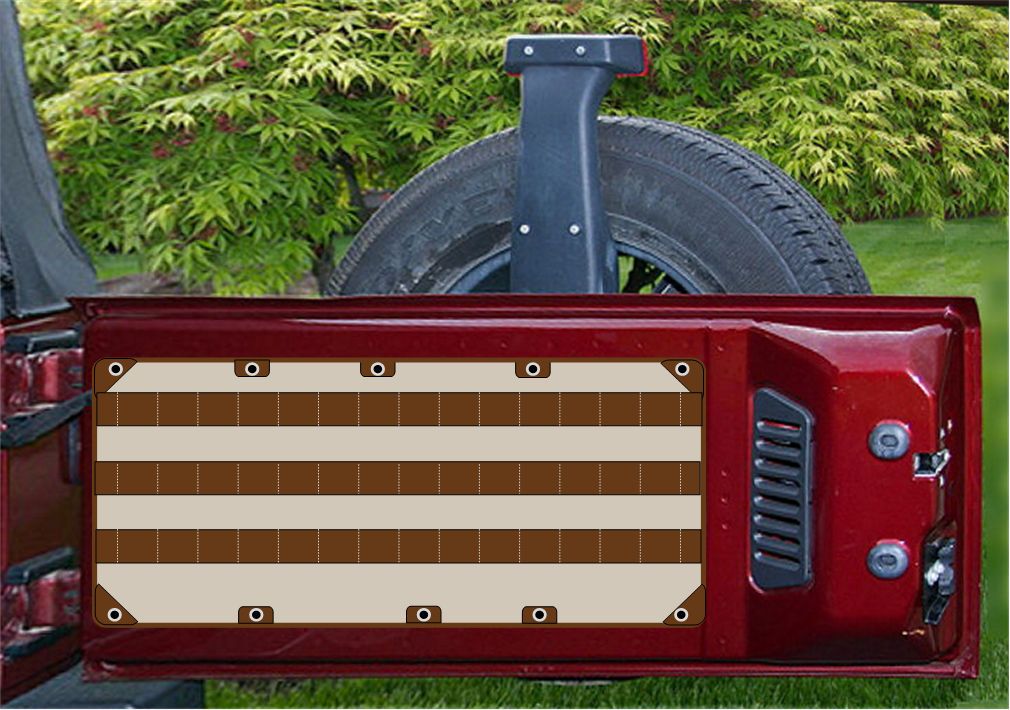

The tailgate panel is a variation of the Molle standard but designed to be stronger so the bags attached to it can hold a decent amount of weight. The dimensions of the grid differ slightly from a standard Molle panel to allow for wider/stronger webbing, but most Molle gear will still be compatible with it, maybe it should be called Molle-HD. This is a concept drawing I did during the design process:

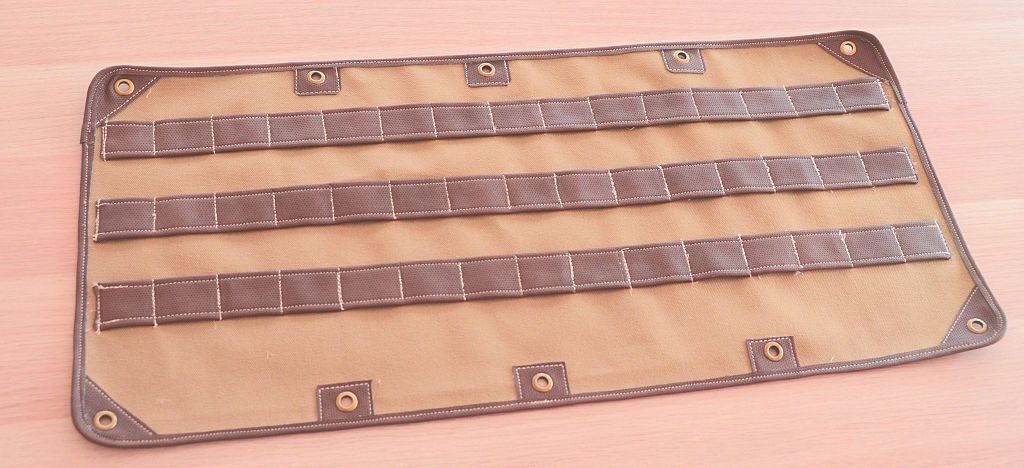

Over the past few days I sewed a rough proof-of-concept:

One unique feature of this panel is that it attaches to the tailgate with no drilling; it uses factory holes in the tailgate for attachment. It installs (or removes) in about a minute.

I don't have any of the company's new design bags here to test with it yet, so here it is with a few Molle pouches.

I plan to sew a second prototype to keep here for testing because I have to turn this one over to the company for them to use as a pattern for getting it into production.