You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Someone did what I am trying to do! Foamie cap / camper on a full sizer...

- Thread starter dbhost

- Start date

Just get a flatbed. Waaayyy easier, RH door, pass through hatches.

ATC camper, but an example.

View attachment 689777View attachment 689778

I am building onto an '04 F150 XLT 4x4 supercab with a 6.5 foot box. Not a 3/4 or 1 ton truck. Budget won't allow for that, and my wife insists on a king size bed so my options are DIY, or DIY.

I have considered pulling the truck bed and replacing it with a flatbed and doing a DIY flatbed camper, but honestly, I would prefer something that is removeable where I can use the truck bed as a regular pickup bed when I need to...

In concept I want o build a wider than normal, longer than normal hi top, or pop top camper shell, and fit it with a folding platform bed. Water system is 4 Aqua tainers with a single pickup that I move from one to another. Gray water capture is a 10 gallon rollaway. Toilet is a 5 gallon flushable.

My typical "Overlanding" trip is going to be things like exploring ghost towns in the Guadalupe mountains, or out into the Ozarks, Honestly if it weren't for beach camping, which has proven up to now to be intolerable in a tent (sand gets blown everywhere in the tent no matter what you do... ), combined with a desire to do more "workcamping" as I work remotely anyway, as long as I have electricity somehow, and steady broadband connection I am golden... In those cases, overnight suburban "Camp Walmart" stays are next to impossible to do with a tent... Oh and I noticed the plate, if I can manage those workcamping arrangements where I can keep WiFi, I hope to head out your way. I've got friends and family in Bend, Salem, Corvallis, Albany etc... VERY familiar with that area, at least I was 30 years ago...

Honestly, if Eureka Campers was still around, I would be looking to see if I could custom order one built for a king size bed and a touch more headroom in the bed area. I am a big dude and do NOT need to be hitting the ceiling rolling over in bed...

Maybe you will find the following link useful?

www.truckcampermagazine.com

www.truckcampermagazine.com

Please be aware that I haven't watched the videos on the linked page.

Carbon Fiber Truck Camper Build: The Titan Expedition Vehicle

Eric Davis designed and built a remarkably innovative hard side pop-up carbon fiber truck camper. Check it out!

Please be aware that I haven't watched the videos on the linked page.

Maybe you will find the following link useful?

Carbon Fiber Truck Camper Build: The Titan Expedition Vehicle

Eric Davis designed and built a remarkably innovative hard side pop-up carbon fiber truck camper. Check it out!www.truckcampermagazine.com

Please be aware that I haven't watched the videos on the linked page.

Awesome. that is another set of links to the same project. The fact that he published on Vimeo, which I find usually only commercial music videos on, is why I hadn't seen this project before now.

Just FWIW, I have zero intent on going with carbon fiber. Too expensive, although it does hit the nail on the head for light weight and strong.

My thought process is going with slightly thinner walls at 1.5" of XPS via 2 layers of 3/4", with either plywood, or southern yellow pine reinforcements at areas like where door locks go through, or where the awning will mount etc... And I will likely end up skinning with fiberglass / epoxy resin.

The advantage of this setup is light weight which is critical for a half ton, and VERY high relatively speaking, insulation value. Although the truck bed isn't exactly well insulated, Just FWIW, mine has a "Bedrug" liner that does offer some, albeit most likely miniscule insulating factor.

Just FWIW, if Eureka Camper was still in business, I wouldn't even consider building my own. Just prior to the owner dying, I was getting priced out for a custom build king bed, mine would have been their first, and no overcab. They are very light at around 600lbs without the overcab, and very lean on the features... There was one I knew of owned by a Youtuber "Travels WIth Yoli" that had a queen overcab that was nice, but not enough headroom in the overcab...

Again, keep weight down, use my existing camping gear. The idea is to replace the tent, and EZ Up with a camper and awning...

brycercampbell

Active member

Hey man, when you start cracking at this, definitely make a build thread. I want to do something similar on my '10 Tundra. Gotta keep it light, not sure if 4WC or DIY. Would love to follow along.Awesome. that is another set of links to the same project. The fact that he published on Vimeo, which I find usually only commercial music videos on, is why I hadn't seen this project before now.

Just FWIW, I have zero intent on going with carbon fiber. Too expensive, although it does hit the nail on the head for light weight and strong.

My thought process is going with slightly thinner walls at 1.5" of XPS via 2 layers of 3/4", with either plywood, or southern yellow pine reinforcements at areas like where door locks go through, or where the awning will mount etc... And I will likely end up skinning with fiberglass / epoxy resin.

The advantage of this setup is light weight which is critical for a half ton, and VERY high relatively speaking, insulation value. Although the truck bed isn't exactly well insulated, Just FWIW, mine has a "Bedrug" liner that does offer some, albeit most likely miniscule insulating factor.

Just FWIW, if Eureka Camper was still in business, I wouldn't even consider building my own. Just prior to the owner dying, I was getting priced out for a custom build king bed, mine would have been their first, and no overcab. They are very light at around 600lbs without the overcab, and very lean on the features... There was one I knew of owned by a Youtuber "Travels WIth Yoli" that had a queen overcab that was nice, but not enough headroom in the overcab...

Again, keep weight down, use my existing camping gear. The idea is to replace the tent, and EZ Up with a camper and awning...

Hey man, when you start cracking at this, definitely make a build thread. I want to do something similar on my '10 Tundra. Gotta keep it light, not sure if 4WC or DIY. Would love to follow along.

My F150 has the 5.4L 3V Triton I am going through, new Melling pump, upgrading to later model VCT system components hot tanking etc... It is going slow. Once the repower is done, I need to redo the actuators for the rear doors, but I am doing the build, slowly in the mean time. I am building out related subsystems, electrical, plumbing, prior to the build of the actual canopy.

The 4WC was a consideration, but lack of a king size option was a deal breaker.

brycercampbell

Active member

Makes sense. Will be following along for sure.My F150 has the 5.4L 3V Triton I am going through, new Melling pump, upgrading to later model VCT system components hot tanking etc... It is going slow. Once the repower is done, I need to redo the actuators for the rear doors, but I am doing the build, slowly in the mean time. I am building out related subsystems, electrical, plumbing, prior to the build of the actual canopy.

The 4WC was a consideration, but lack of a king size option was a deal breaker.

Would you save any weight by replacing the pickup bed with an aluminum flatbed?... I have considered pulling the truck bed and replacing it with a flatbed and doing a DIY flatbed camper, but honestly, I would prefer something that is removable where I can use the truck bed as a regular pickup bed when I need to...

Epoxy resin and fiberglass can be quite strong.... Just FWIW, I have zero intent on going with carbon fiber. Too expensive, although it does hit the nail on the head for light weight and strong.

My thought process is going with slightly thinner walls at 1.5" of XPS via 2 layers of 3/4", with either plywood, or southern yellow pine reinforcements at areas like where door locks go through, or where the awning will mount etc... And I will likely end up skinning with fiberglass / epoxy resin. ...

Would you save any weight by replacing the pickup bed with an aluminum flatbed?

Epoxy resin and fiberglass can be quite strong.

Agreed, however, in my experience, and I may be wrong here, but fiberglass / epoxy resin, or poly resin are not big fans of holding screws.

I am planning on installing a residential style door lock and mortising into wood should be MUCH simpler than fiberglassing.

And yes, I would likely shave weight but increase cost and complexity of the build by going with an aluminum flatbed. I am trying to hold costs down.

You might find the following links useful:Agreed, however, in my experience, and I may be wrong here, but fiberglass / epoxy resin, or poly resin are not big fans of holding screws.

I am planning on installing a residential style door lock and mortising into wood should be MUCH simpler than fiberglassing.

And yes, I would likely shave weight but increase cost and complexity of the build by going with an aluminum flatbed. I am trying to hold costs down.

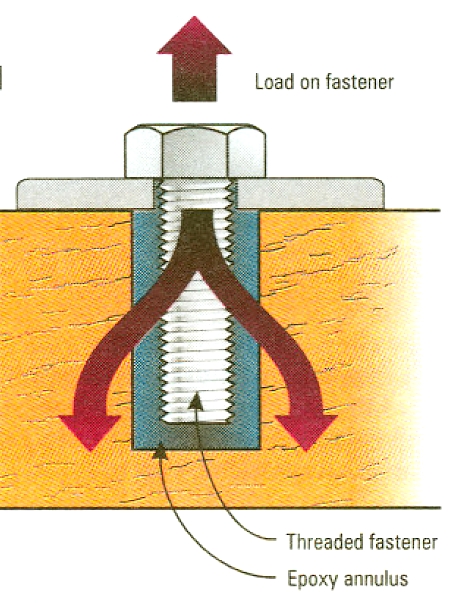

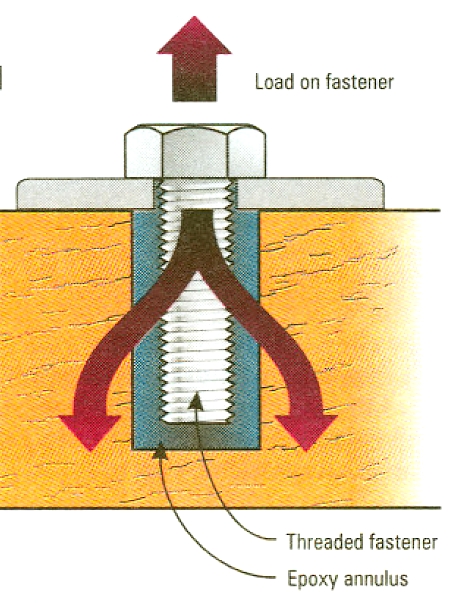

Bonding Fasteners in High-Density Urethane Foam - Epoxyworks

Tips for Sign Builders & Everyone Else by Bruce Niederer — GBI Technical Advisor Above: Bonding fasteners in high-density urethane (HDU) foam calls for drilling an oversized hole slightly shallower than the fastener length and setting the fastener in an annulus of thickened epoxy. Many of our...

More on Hardware Bonding - Epoxyworks

General considerations for epoxy bonded fasteners in wood By Robert Monroe With epoxy bonded fasteners, the idea is to balance the three parts, (fastener, epoxy and wood/hole) to obtain optimum performance. The key information needed is the tensile strength of the fastener, the shear strength of...

Bonding Fasteners and Hardware | WEST SYSTEM Epoxy

Improve load carrying capacity by spreading the fastener’s load into a greater area of the substrate with WEST SYSTEM Epoxy.

Bonding with Epoxy Fillets - Epoxyworks

By Tom Pawlak — GBI Technical Advisor Building with epoxy fillets is especially beneficial when attaching bulkheads to hull sides, attaching hull sides to hull bottoms where the faces of the plywood are coming together at ever-changing angles. Gluing plywood structures together with epoxy...

You might find the following links useful:

Bonding Fasteners in High-Density Urethane Foam - Epoxyworks

Tips for Sign Builders & Everyone Else by Bruce Niederer — GBI Technical Advisor Above: Bonding fasteners in high-density urethane (HDU) foam calls for drilling an oversized hole slightly shallower than the fastener length and setting the fastener in an annulus of thickened epoxy. Many of our...www.epoxyworks.com

More on Hardware Bonding - Epoxyworks

General considerations for epoxy bonded fasteners in wood By Robert Monroe With epoxy bonded fasteners, the idea is to balance the three parts, (fastener, epoxy and wood/hole) to obtain optimum performance. The key information needed is the tensile strength of the fastener, the shear strength of...www.epoxyworks.com

Bonding Fasteners and Hardware | WEST SYSTEM Epoxy

Improve load carrying capacity by spreading the fastener’s load into a greater area of the substrate with WEST SYSTEM Epoxy.www.westsystem.com

Bonding with Epoxy Fillets - Epoxyworks

By Tom Pawlak — GBI Technical Advisor Building with epoxy fillets is especially beneficial when attaching bulkheads to hull sides, attaching hull sides to hull bottoms where the faces of the plywood are coming together at ever-changing angles. Gluing plywood structures together with epoxy...www.epoxyworks.com

That'll help with the weight, and rot considerations of using wood...

The reason I suggested a flatbed was to make the build simple. An aluminum flat bed would be lighter than the original bed/tailgate. You could also do a 7x7 ft flatbed, it would stick out only 3" past the cab and probably not go past the rear bumper. You don't have to use a $12,000 Austraiian imported bed, the 7x8 1/2 Protec flatbed cost me $3500.

When you build the box, everything is straight and square. It would also fit any future truck you bought. Put a plywood floor in it and you could remove it from the flatbed. You would also have a huge sleep bed laying cross-ways. You get a 7x7 floor, instead of 4x6.

It is also flexible on the man door location, having a door on the back bumper is a pain and usually dirty/dusty. Side hatches can then be used.

When you build the box, everything is straight and square. It would also fit any future truck you bought. Put a plywood floor in it and you could remove it from the flatbed. You would also have a huge sleep bed laying cross-ways. You get a 7x7 floor, instead of 4x6.

It is also flexible on the man door location, having a door on the back bumper is a pain and usually dirty/dusty. Side hatches can then be used.

The reason I suggested a flatbed was to make the build simple. An aluminum flat bed would be lighter than the original bed/tailgate. You could also do a 7x7 ft flatbed, it would stick out only 3" past the cab and probably not go past the rear bumper. You don't have to use a $12,000 Austraiian imported bed, the 7x8 1/2 Protec flatbed cost me $3500.

When you build the box, everything is straight and square. It would also fit any future truck you bought. Put a plywood floor in it and you could remove it from the flatbed. You would also have a huge sleep bed laying cross-ways. You get a 7x7 floor, instead of 4x6.

It is also flexible on the man door location, having a door on the back bumper is a pain and usually dirty/dusty. Side hatches can then be used.

A lot less cutting in and around to make the bumpout back work for sure...

rruff

Explorer

Just FWIW, I have zero intent on going with carbon fiber. Too expensive, although it does hit the nail on the head for light weight and strong.

Fiberglass Supply has some 11oz carbon that is very reasonable. I used it for the floor/base because I wanted it to be stiff. Carbon is a little lighter and stronger than fiberglass, but the main difference is stiffness... it's 2.5 to 3x the stiffness. In my experiments it didn't seem to handle impact as well as FG, so I didn't use it in the rest of the camper. https://shop.fiberglasssupply.com/Carbon_Fiber_Cloth-11_1oz_6K_Carbon_Fiber_Fabric_60_Wide.html

If you use the cheap hardware XPS I'd suggest sanding and then texturing the surface with a wallpaper perforator. Work the epoxy into the voids (get the bubbles out) and do your layup before the epoxy fully cures. I'd also use wood "stringers" in the core as well for piece of mind and internal hard points. I know of a few people who've had the fiberglass and foam part ways...