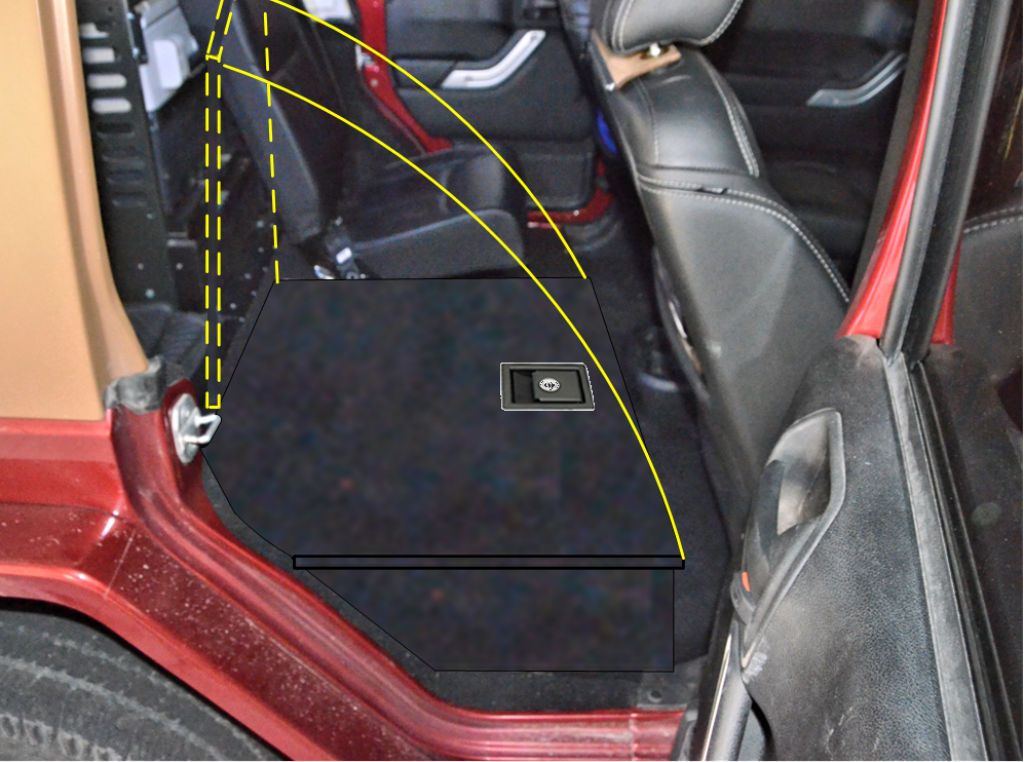

If you follow this thread you may recall the changing room/annex I made for my RTT a few months back:

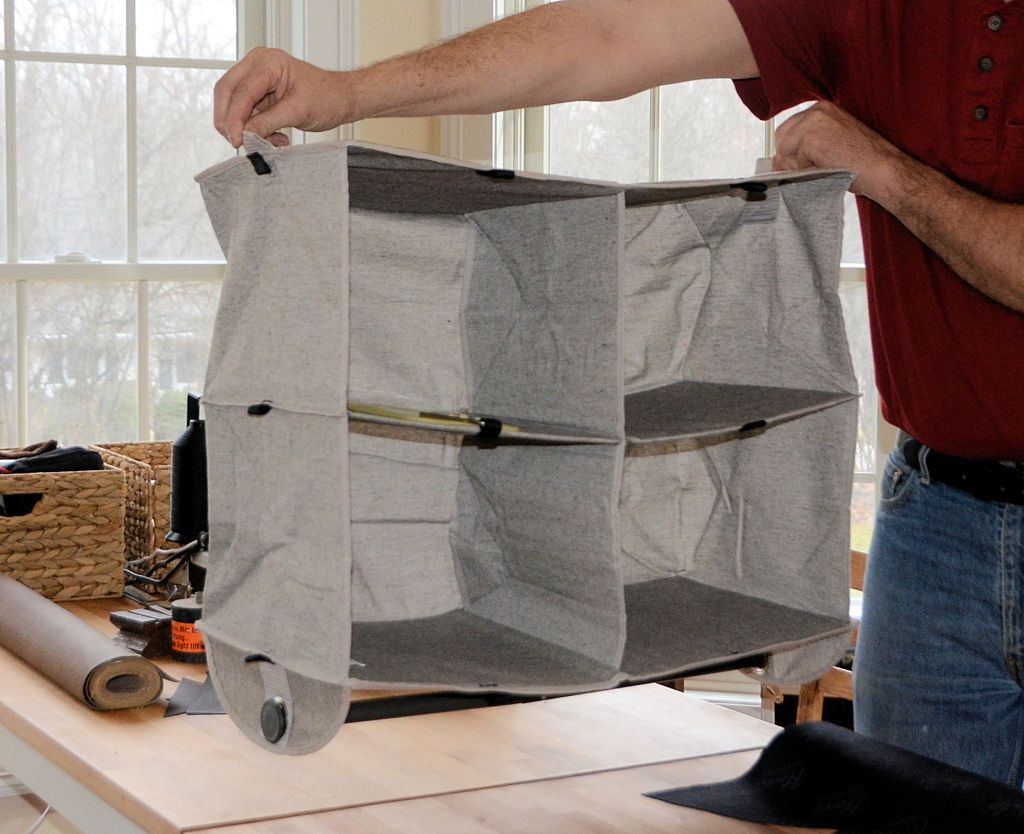

To make it functional as a changing room, I installed hooks to the underside of the tent base to hang a set of cloth closet organizer shelves; I posted this photo of me holding the shelves out as if they're hanging because the tent wasn't on the Jeep at the time, it was stored vertically against the wall.

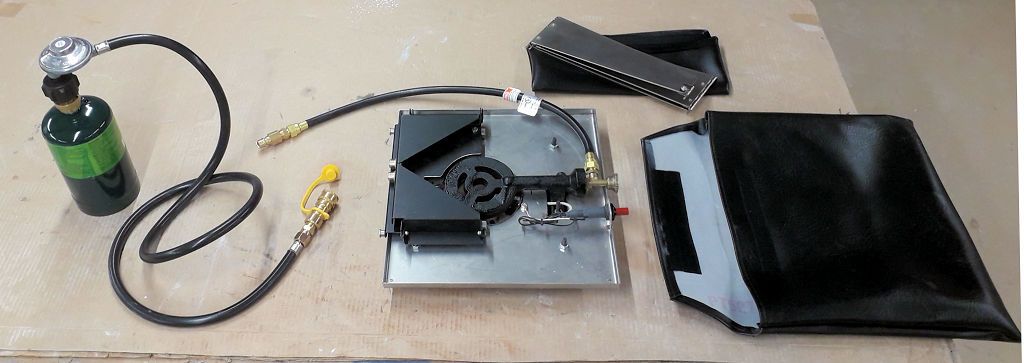

My projects are all about the details, so I decided that my princess should have a mirror. I picked up a Coughlan's Camp Mirror for about $4 at a local outdoor store:

https://www.coghlans.com/products/camping-mirror-650

To hang the mirror, I sewed small loops of 3/4"-wide webbing to the edges of all the shelves, the mirror has a stand that also serves was a hanger so she'll be able to hang it wherever she wants using those loops.

As long as I was sewing, I also sewed loops to the side of the shelf casing in case she wants to hang it there. Or maybe she'll find something else that needs to be hung.

The shelves stay on the tent when it folds up, and because of these loops the mirror can fold up with the shelves as well. In this photo the mirror is swung up on a shelf, the shelves can be folded up and the mirror will stay there.

Probably the next time I put the tent on the Jeep will be when I'm preparing for Overland West, so I'll take some proper photos of the shelves and mirror in the annex then.

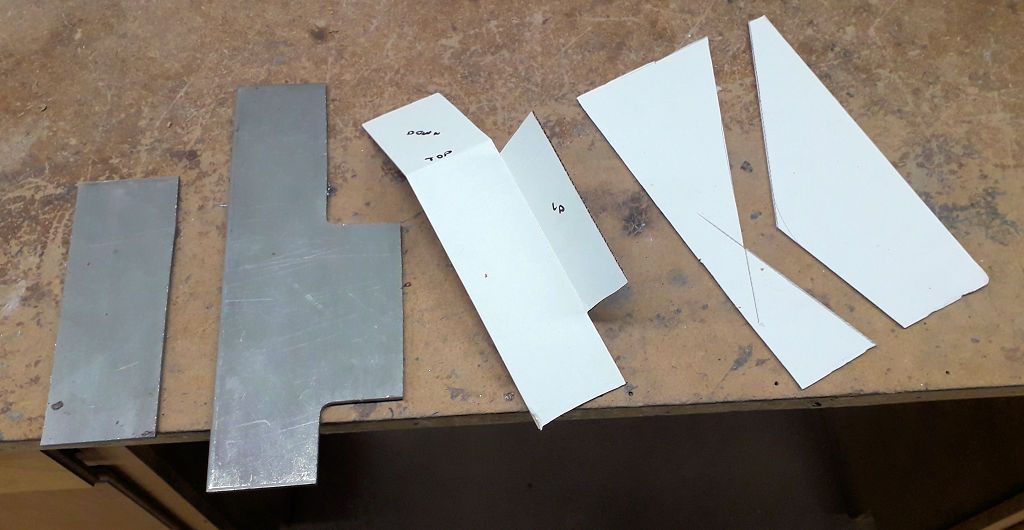

Another sewing project... a company you all know is approaching a big anniversary and they're building a special Jeep to celebrate the event. Based on my designs for Overland Outfitters, they've asked Overland Outfitters (and me) to participate in the project with something special and custom for their build. I can't say any more about it other than it involves my sewing machine, and if they let me do it as I've proposed the end result of my participation will be a product exclusive to Quadratec rather than a one-off just for the anniversary Jeep.