In the next month I’m having 4.11s and an E-locker installed in the Dana 44 to match the front Dana 30 currently under the Jeep.

With a bit of research I decided on a method for painting the Dana 44 that I’d sourced a year or so back. I ultimately went with paint verses powder coating for the simple reason of as the paint gets messed up all I need to do is run to Home Depot or Ace and pick a couple cans of paint and recast the axle where the paint is damaged.

Previous experience with powder coating has shown that as it becomes damaged you can’t repair it. As it starts to peel/strip you need to remove the entire coat and start over. Now while the paint won’t last as long it can be easily fixed, therefore I’m theory it should last longer and prevent rust with routine upkeep.

Here’s what I did to paint the axle over 3 days.

Day 1:

After removing the drum brakes and backing plates and axle shafts all the built up grease, dirt, flaking coating and rust with a wire cup brush. (This step took longer than anticipated as the there was much more grease than I originally thought.) Then I washed the axle housing to remove residual grease and dirt with Dawn dawn dish soap a scrub brush.

Day 2:

Sprayed on 3 coats of Rust-O-leum automotive primer and allowed it to cure for 24 hours.

Day 3:

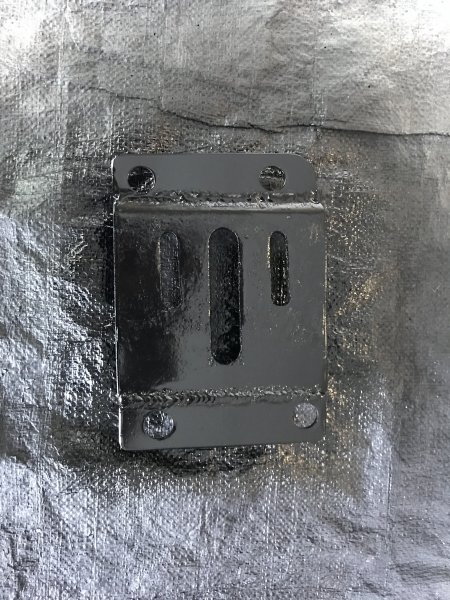

Applied 3 coats of Rust-O-leum appliance epoxy. With a 30-minute dry time between each coat. Where it now sits for the next week to allow the paint to fully cure. The appliance epoxy has become my go to for rattle can paints as I've found it to be more durable than the regular Rust-O-leum.

It’s took awhile but it works well and is not costly. All told I’m $20 in to it. I’m hoping the that it will hold up well with the knowledge that it it’s going to scuff on the first impact and/or wear off with enough time.

Lastly; currently the Jeep has 30” BFGoodrich All Terrains. To bring the RPMs back down after the 4.11s are installed some new kicks in the flavor of 33x10.5x15 BFG KM3 were purchased during the 4WD holiday day. I’ve heard really good things regarding the KM3.

I knew new I didn’t want to go any wider than 10.5 as I want to keep the tires tucked inside the fenders and the narrow tires will track better down the road. Where I really struggled was with which size to go with. I repeatedly went back and forth between 31s and 33s. Both were practical and eventually the aesthetics won out. I’ve always thought the LWB Comanches looked better with a little bigger tire size.

With a bit of research I decided on a method for painting the Dana 44 that I’d sourced a year or so back. I ultimately went with paint verses powder coating for the simple reason of as the paint gets messed up all I need to do is run to Home Depot or Ace and pick a couple cans of paint and recast the axle where the paint is damaged.

Previous experience with powder coating has shown that as it becomes damaged you can’t repair it. As it starts to peel/strip you need to remove the entire coat and start over. Now while the paint won’t last as long it can be easily fixed, therefore I’m theory it should last longer and prevent rust with routine upkeep.

Here’s what I did to paint the axle over 3 days.

Day 1:

After removing the drum brakes and backing plates and axle shafts all the built up grease, dirt, flaking coating and rust with a wire cup brush. (This step took longer than anticipated as the there was much more grease than I originally thought.) Then I washed the axle housing to remove residual grease and dirt with Dawn dawn dish soap a scrub brush.

Day 2:

Sprayed on 3 coats of Rust-O-leum automotive primer and allowed it to cure for 24 hours.

Day 3:

Applied 3 coats of Rust-O-leum appliance epoxy. With a 30-minute dry time between each coat. Where it now sits for the next week to allow the paint to fully cure. The appliance epoxy has become my go to for rattle can paints as I've found it to be more durable than the regular Rust-O-leum.

It’s took awhile but it works well and is not costly. All told I’m $20 in to it. I’m hoping the that it will hold up well with the knowledge that it it’s going to scuff on the first impact and/or wear off with enough time.

Lastly; currently the Jeep has 30” BFGoodrich All Terrains. To bring the RPMs back down after the 4.11s are installed some new kicks in the flavor of 33x10.5x15 BFG KM3 were purchased during the 4WD holiday day. I’ve heard really good things regarding the KM3.

I knew new I didn’t want to go any wider than 10.5 as I want to keep the tires tucked inside the fenders and the narrow tires will track better down the road. Where I really struggled was with which size to go with. I repeatedly went back and forth between 31s and 33s. Both were practical and eventually the aesthetics won out. I’ve always thought the LWB Comanches looked better with a little bigger tire size.