You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alternative Solar Panel Installation on Hardshell RTTs?

- Thread starter erstwild

- Start date

I really don't velcro will hold in the wind created by a vehicle on the road. You could be the test case for this application.

this isnt your fathers velcro !! todays velcro is rediculously strong but id worry about the connect to the shell and the panels. the velcro itself will hold.

Hillbilly Heaven

Explorer

Why not magnets and metal plates. You cold felt line the contacting surfaces so no damage to either the inside or outside surfaces. I wouldn't want adhesive of the Velcro left remaining after UV rays damaged the velcro.

Thanks so much everyone for your prompt replies and ideas. Felt lined thin magnets and metal plate idea is interesting! I wonder if that would have any negative impact on the electronics in the solar panel have to check first. I agree modern velcro is probably strong enough but the adhesive would be the weak point (and could still be destructive to remove to the gelcoat). Also glad to clarifying, VHB is 3M Very High Bond Tape which is great if you want to permanently mount something securely which is common for some folks to attach traditional metal framed solar panels to van roofs among other applications.

Hillbilly Heaven

Explorer

Yes VHB is a great adhesive but will be impossible to remove later on. The double hook velcro is very strong. Problem with Velcro exposed long term to sunlight is the nylon used to make it. I know of no UV resistant Velcro. The VHB itself will not damage fiberglass but trying to remove it would.

The magnets will not interfere with the solar panel at all. The only thing it will interfere with would be a compass either electronic with a magnetic sensor or mechanical within about a foot of the magnet. Magnets do not interfere with electronics.

The magnets will not interfere with the solar panel at all. The only thing it will interfere with would be a compass either electronic with a magnetic sensor or mechanical within about a foot of the magnet. Magnets do not interfere with electronics.

Yes VHB is a great adhesive but will be impossible to remove later on. The double hook velcro is very strong. Problem with Velcro exposed long term to sunlight is the nylon used to make it. I know of no UV resistant Velcro. The VHB itself will not damage fiberglass but trying to remove it would.

The magnets will not interfere with the solar panel at all. The only thing it will interfere with would be a compass either electronic with a magnetic sensor or mechanical within about a foot of the magnet. Magnets do not interfere with electronics.

This is great! I'm going to put together some magnet/plate connectors and give this a try.

Hillbilly Heaven

Explorer

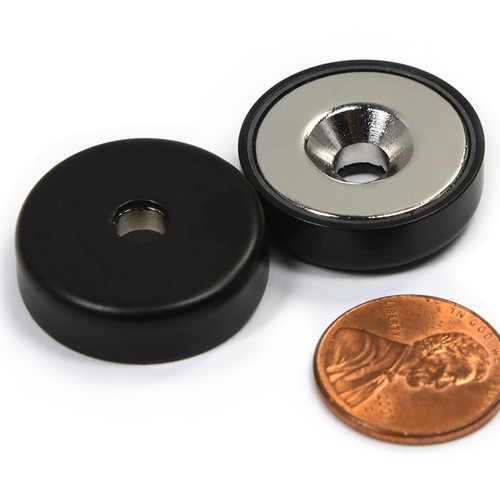

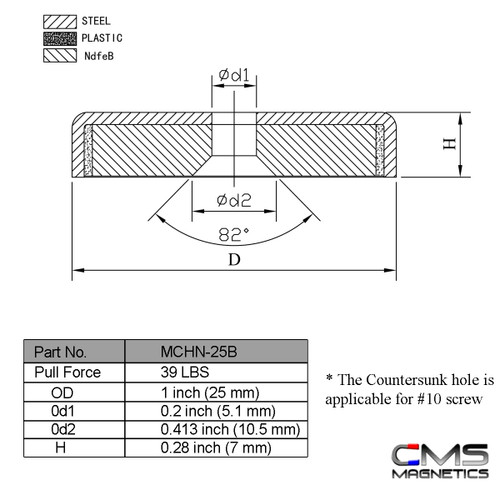

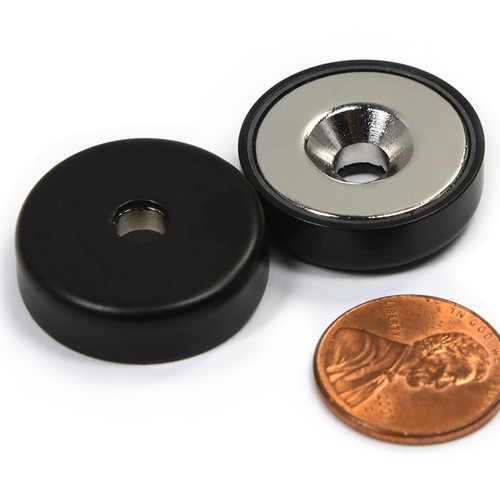

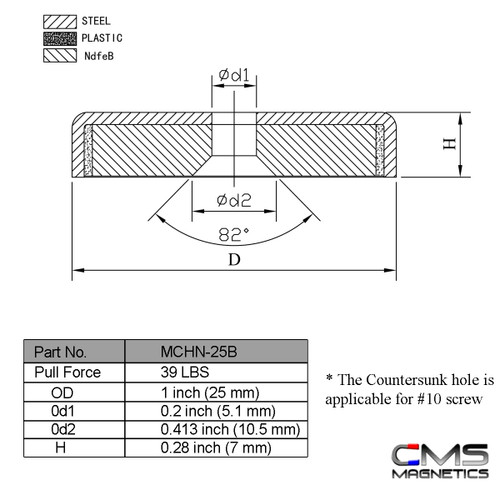

Something like this would be perfect and could be removed without having to use a crane. 39 pounds of force 1" diameter with countersunk hole in center. Use 304 stainless countersunk screw with with the panel sandwiched between two 304 stainless flat washers and stainless nylock nut. Reason to use 304 stainless hardware is that it is non magnetic. Looks like a 10-32 or 10-24 screw can fit hole in magnet.

https://www.magnet4sale.com/39-lb-holding-power-neodymium-cup-magnet-1-black-mchn-25b/

https://www.magnet4sale.com/39-lb-holding-power-neodymium-cup-magnet-1-black-mchn-25b/

Something like this would be perfect and could be removed without having to use a crane. 39 pounds of force 1" diameter with countersunk hole in center. Use 304 stainless countersunk screw with with the panel sandwiched between two 304 stainless flat washers and stainless nylock nut. Reason to use 304 stainless hardware is that it is non magnetic. Looks like a 10-32 or 10-24 screw can fit hole in magnet.

https://www.magnet4sale.com/39-lb-holding-power-neodymium-cup-magnet-1-black-mchn-25b/

Wow, thanks so much for doing that legwork for me! Apologies, if I am misunderstanding anything, but just to clarify, I would be planning on using a renogy 100 watt flexible panel (no standard mount points). I’m not quite sure how your design comes together exactly.

What I am thinking is using 3M VHB to attach thin steel circular plates to the four corners of the panel. Then add thin layer of plastic, felt, or even just tape to bottom of plates to not scuff fiberglass. Inside the Columbus shell it is carpeted already so all I would need to do is line up and attach sufficiently strong magnets inside.

Do let me if you like that idea or if I am off base and misunderstanding your original recommendation. Thx

Hillbilly Heaven

Explorer

My idea was based on the flexible panel having some type of mounting holes. It is the reverse of what you described with the magnets on the outside. Your way should work if your magnets are strong enough and the distance between magnet and plate is not too far.

My idea was based on the flexible panel having some type of mounting holes. It is the reverse of what you described with the magnets on the outside. Your way should work if your magnets are strong enough and the distance between magnet and plate is not too far.

That is true. It would be more like the reverse case. What do you think of using different polarity magnets one on each side as opposed to one magnet and steel plate?

That 39 pound is likely meaning axial force, pulling straight off. Be aware, force to slide the magnet along and then free of its attached to surface will be considerable less.

That is a good point as well. I would hope that since the panels only weigh a few pounds that would be sufficient to hold them.

Hillbilly Heaven

Explorer

Using opposite magnets might work but I think you will find the cupped ones I link as all having the same polarity. I can't say for sure unless they just random assembled them then it would be like a grab bag buying them. It would help with holding power vs mag and plate. I was thinking in the less than 100 pound rating because you have to remove them at some point. I wouldn't want to risk ripping the vinyl of the solar panel.

Unfortunately, it seems like the magnet idea won't end up working quite the way I will need it to after some additional consultation.

How about this for a crazy idea? Use a bunch of those large 5 lb each 3M outdoor command strips around the edges. The lensun 100 watt flexi panel I am buying is only 5lbs with a fiberglass sheet backing. I could clean the mounting point with alcohol and then attach fiberglass to fiberglass, haha.

How about this for a crazy idea? Use a bunch of those large 5 lb each 3M outdoor command strips around the edges. The lensun 100 watt flexi panel I am buying is only 5lbs with a fiberglass sheet backing. I could clean the mounting point with alcohol and then attach fiberglass to fiberglass, haha.

Forum statistics

Members online

- Bergger

- Herbc

- osukj04

- XJLI

- Geared4adventure

- Savagenut

- Timraphael33

- 287sds

- fisher205

- devilstang

- emulous74

- Zeep

- RoverGS

- zimflux

- Dougnuts

- Alwaysstranded

- BlueLantern

- Corona_Cave_Garage

- habakuk

- naks

- zimm

- SaltStainedEyes

- Waygoner

- jacobmatat

- lcdck

- Panthera

- Toytaco2

- discodisco

- Shermanator

- CoExplorer

- YukonMontanaTannerTrapper

- g_m

- Rancid

- TexasD-90

- jebaker

- whododat

- Kingsize24

- Superinferno

- jsmo

- scottrinne

- Wnick308

- Doslocos

- Banzai Jimmy

- George Donner

- swinnie

- Elkfitness

- tacollie

- dstaniec

- teethless

- BlackDogTravelers

Total: 870 (members: 53, guests: 817)